A kind of non-stoichiometric copper bismuth acid nanomaterial and its preparation method and application

A non-stoichiometric, nano-material technology, applied in the field of non-stoichiometric copper bismuthate nano-materials and its preparation, can solve the problems of reaction time repeatability and efficiency limitation, and achieve low cost, good etching effect, good Dispersion and Uniformity Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of non-stoichiometric ratio copper bismuth acid nanometer material, its preparation method comprises the steps:

[0033] Mix 1mmol of bismuth nitrate pentahydrate with 20mL of copper acetate aqueous solution with a concentration of 5g / L, place the resulting reaction solution in a 100mL glass beaker, and disperse with ultrasonic stirring to obtain a uniform suspension, then add dropwise 5mol / L of potassium hydroxide solution 10mL until the solution was separated, and the obtained reaction system was aged for 24h (20°C). After the reaction, the obtained product was centrifuged to remove the residual solvent and dried at 60°C for 24h. After cooling, the non-stoichiometric ratio was obtained. Copper bismuth oxide nanomaterials.

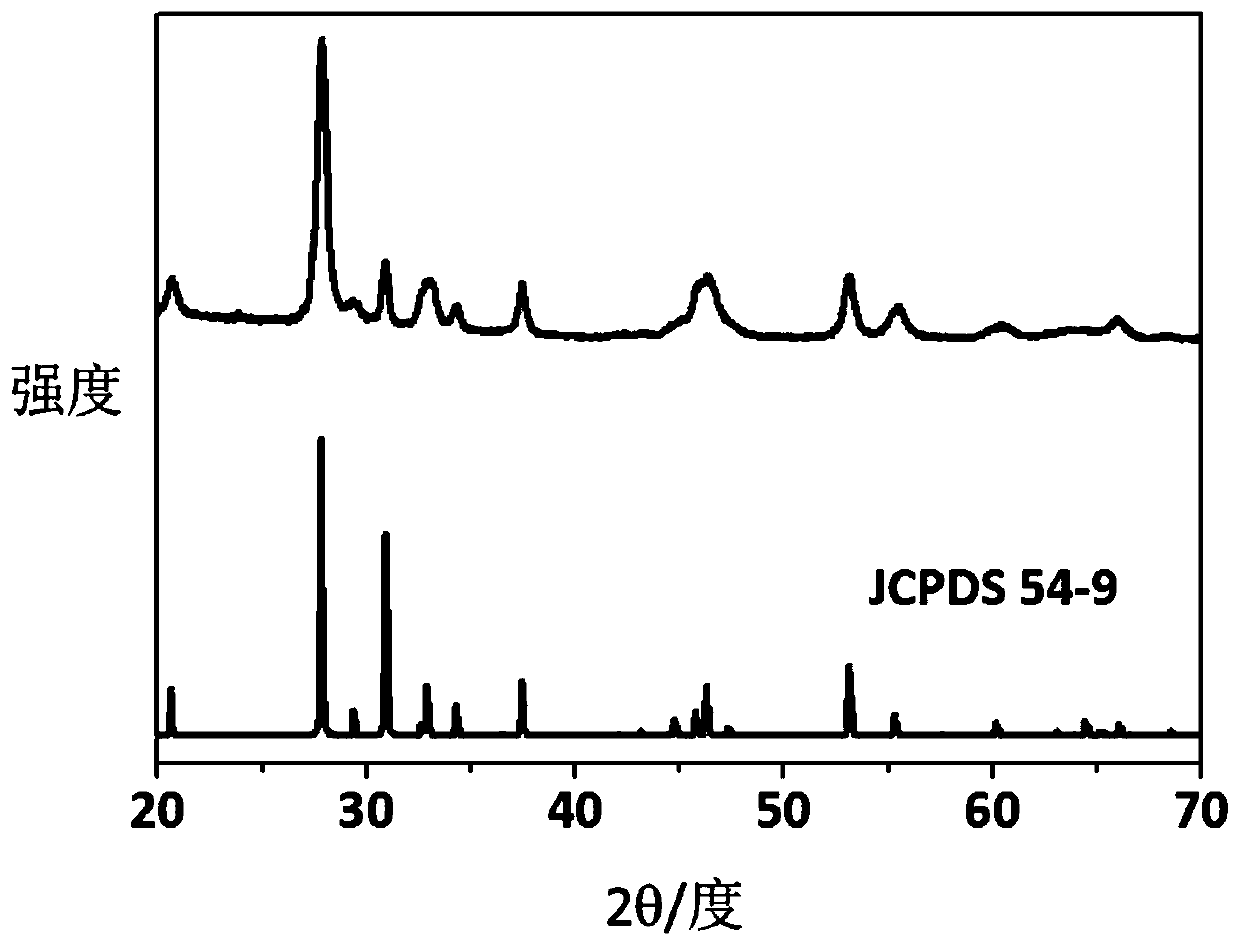

[0034] Adopt Brukeraxs D8 type X-ray diffraction analyzer (XRD) to carry out X-ray diffraction analysis to the product obtained in this embodiment, the results are shown in figure 1 . As can be seen from the spectrum, the main peak of the ...

Embodiment 2

[0038] A kind of non-stoichiometric ratio copper bismuth acid nanometer material, its preparation method comprises the steps:

[0039] Mix 2mmol of bismuth nitrate pentahydrate with 20mL of 10g / L copper acetate aqueous solution, place the reaction solution in a 100mL glass beaker, and disperse with ultrasonic stirring to obtain a uniform suspension, then add dropwise 10mL of 10mol / L potassium hydroxide solution to the solution Layered, the obtained reaction system was left to stand for aging for 24h (20°C). After the reaction, the obtained product was centrifuged to remove the residual solvent and dried at 60°C for 24h. After cooling, the sea urchin-like non-stoichiometric bismuth acid was obtained. copper nanomaterials.

Embodiment 3

[0041] A kind of non-stoichiometric ratio copper bismuth acid nanometer material, its preparation method comprises the steps:

[0042] Mix 2mmol of bismuth nitrate pentahydrate with 20mL of copper acetate aqueous solution with a concentration of 5g / L, place the resulting reaction solution in a 100mL glass beaker, and disperse with ultrasonic stirring to obtain a uniform suspension, then add dropwise 0.5mol / L of potassium hydroxide Solution 10mL until the solution is separated, and the mixture is left to age for 12h (20°C); after the reaction, the product obtained is centrifuged to remove the residual solvent and dried at 60°C for 24h, and the sea urchin-like non-stoichiometric bismuth acid is obtained after cooling copper nanomaterials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com