Method for preparing NCA positive electrode material of lithium-ion battery by utilizing coprecipitation method

A technology for lithium ion batteries and cathode materials, which is applied in the field of preparing lithium ion battery NCA cathode materials by co-precipitation method, can solve the problems of poor cycle performance and poor particle uniformity, and achieves low equipment requirements, uniform shape and good cycle. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Synthesis of precursors

[0029] Weigh 0.08mol analytically pure NiSO 4 ·6H 2 O (21g), 0.015mol analytically pure CoSO 4 ·7H 2 O (4.21g) and 0.025mol analytically pure Al 2 (SO 4 ) 3 18H 2 O (16.6g), the three were dissolved in 300ml of deionized water successively to form a mixed salt solution, marked as solution A;

[0030] Weigh 0.4g NaOH and 0.7g sulfosalicylic acid respectively, mix them with a certain volume of 0.2mol / L NH 3 ·H 2 O mixed solution was dissolved in 300mL of deionized water, marked as solution B;

[0031] Add solution B to the peristaltic pump and drop it into solution A at a certain speed, and keep the pH value of the reaction process at 11 by strictly controlling the titration speed, while keeping the mixed solution constantly stirring;

[0032] Control the aging time for 11 hours to control the degree of reaction. During the aging process, keep the ambient temperature at 65°C. After the aging process, use deionized water and alcohol ...

Embodiment 2

[0037] (1) Synthesis of precursors:

[0038] Weigh 0.08mol analytically pure NiSO 4 ·6H 2 O (21g), 0.015mol analytically pure CoSO 4 ·7H 2 O (4.21g) and 0.025mol analytically pure Al 2 (SO4) 3 18H 2 O (16.6g), the three were dissolved in 300ml of deionized water successively to form a mixed salt solution, marked as solution A;

[0039] Weigh 0.4g NaOH and 0.7g sulfosalicylic acid respectively, mix them with a certain volume of 0.2mol / L NH 3 ·H 2 O mixed solution was dissolved in 300mL of deionized water, marked as solution B;

[0040] Control the aging time for 11 hours to control the degree of reaction. During the aging process, keep the ambient temperature at 65°C. After the aging process, use deionized water and alcohol to repeatedly centrifuge the precipitate obtained after aging until the solution If it is neutral, the neutral sample after cleaning is placed in a vacuum drying oven at 130°C for 8 hours and then sieved to obtain Ni 0.8 co 0.15 Al 0.05 (OH) 2 P...

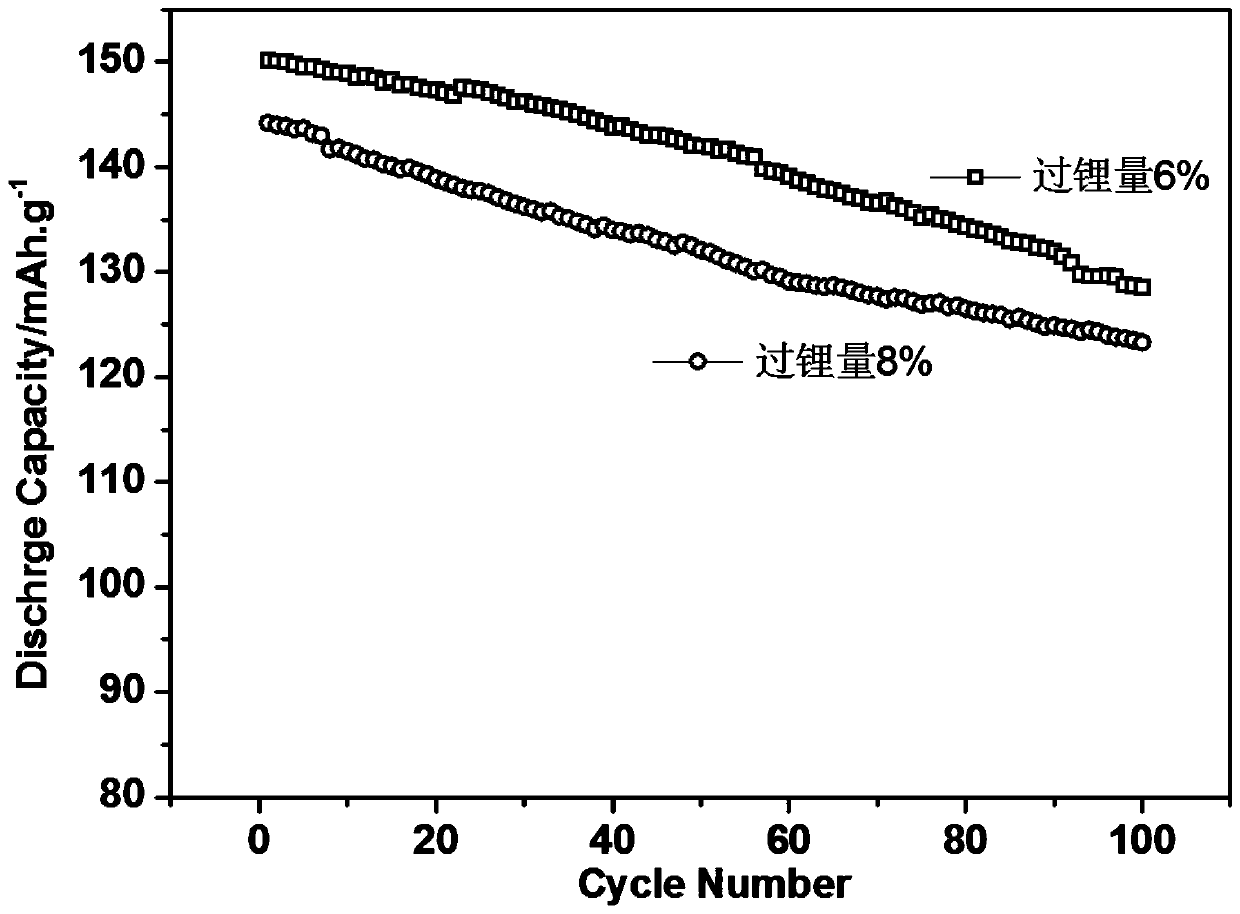

Embodiment 3

[0044] (1) Synthesis of precursors:

[0045] Weigh 0.08mol analytically pure NiSO 4 ·6H 2 O (21g), 0.015mol analytically pure CoSO 4 ·7H 2 O (4.21g) and 0.025mol analytically pure Al 2 (SO 4 ) 3 18H 2 O (16.6g), the three were dissolved in 300ml of deionized water successively to form a mixed salt solution, marked as solution A;

[0046] Weigh 0.4g NaOH and 0.7g sulfosalicylic acid respectively, mix them with a certain volume of 0.2mol / L NH 3 ·H 2 O mixed solution was dissolved in 300mL of deionized water, marked as solution B;

[0047] Control the aging time for 11 hours to control the degree of reaction. During the aging process, keep the ambient temperature at 65°C. After the aging process, use deionized water and alcohol to repeatedly centrifuge the precipitate obtained after aging until the solution If it is neutral, the neutral sample after cleaning is placed in a vacuum drying oven at 130°C for 8 hours and then sieved to obtain Ni 0.8 co 0.15 Al 0.05 (OH) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com