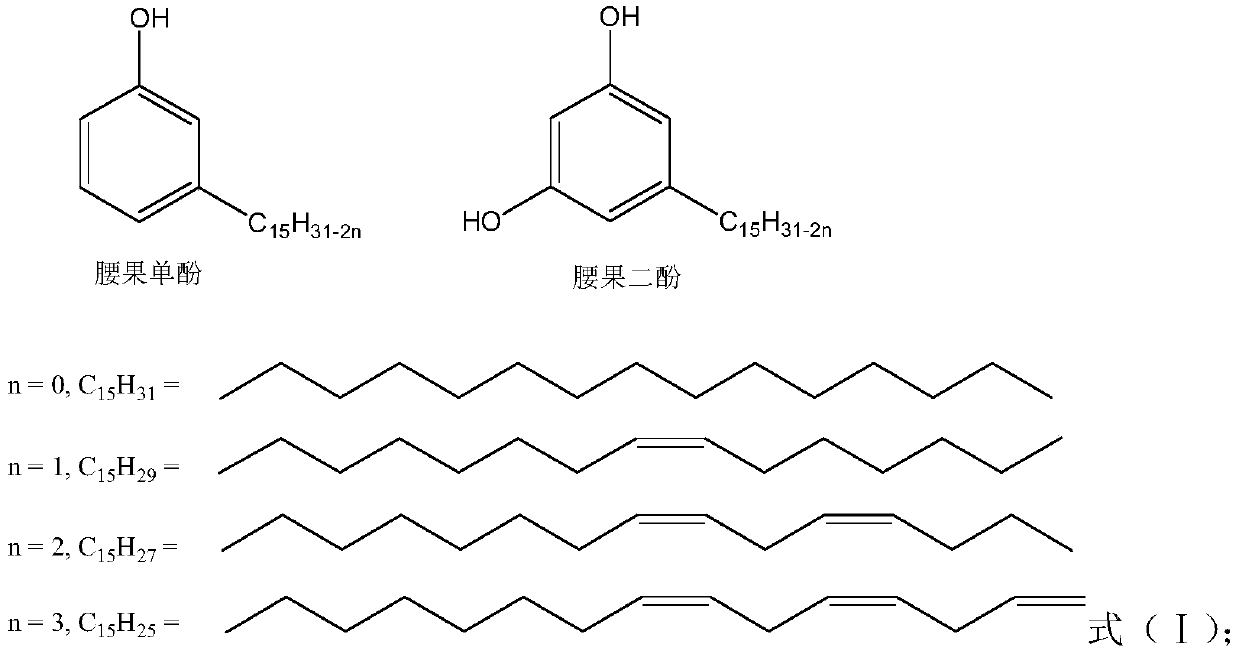

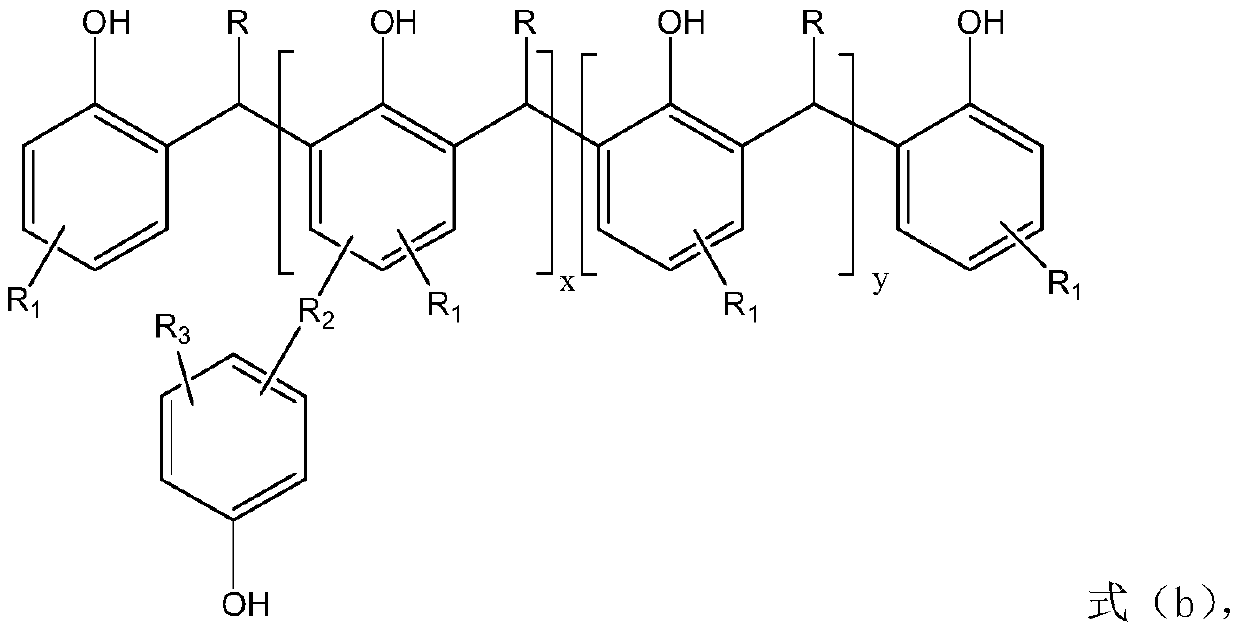

A kind of cardanol modified phenolic resin used as adhesive for rubber and its products

A technology of phenolic resin and cardanol, used in transportation and packaging, special tires, tire parts, etc., can solve the problems of complex process, consumption of phenol reactive points, smoke and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] In a 5L four-necked round-bottomed reaction flask equipped with a stirrer, thermometer, reflux condenser and dropping funnel, add 1880g phenol, 235g cardanol, 25g oxalic acid, heat to 95-100°C, then drop in 90 minutes Add 1260g of 37% formaldehyde solution, and continue to reflux for 30 minutes after the dropwise addition. At this time, change the reflux device to a distillation device, heat up and steam the water and part of unreacted phenol generated by the reaction. When the temperature reaches 114-115 ° C, no longer If there is water to evaporate, continue to heat up to 195-200°C, then add steam to distill for 60 minutes, then continue vacuum distillation at 195-200°C for 60 minutes (vacuum degree -95KPa), and obtain cardanol modified phenolic resin after breaking the vacuum 2250 grams. The softening point of the resin is 95°C, and the free phenol is 0.32%.

Embodiment 2

[0097] In a 5L four-necked round-bottomed reaction flask equipped with a stirrer, a thermometer, a reflux condenser and a dropping funnel, add 1880g of phenol and 10g of p-toluenesulfonic acid monohydrate, heat to 95-100°C, and then Add 1170g of 37% formaldehyde aqueous solution dropwise, and continue to reflux for 30 minutes after the addition is completed. At this time, the reflux device is changed to a distillation device, and then the temperature is raised and the water generated by the reaction and part of the unreacted phenol are evaporated, and the temperature reaches 114-115°C When no more water is distilled out, add 235 grams of cardanol, change the distillation device to a reflux device, continue to heat up to 180-185 ° C and react for 60 minutes, then add 8 grams of triethanolamine and continue to stir for 5-10 minutes. Change the reflux device to a distillation device, continue to heat up to 195-200°C, and then pass in steam for distillation for 60 minutes, then con...

Embodiment 3

[0099] The cardanol-modified phenolic resin prepared by embodiment 1, embodiment 2 is tested and verified in the rubber formula, and with resorcinol, commercially available SL-3022 resin (resorcinol formaldehyde resin) and PN760 resin ( Butyl carbamate modified phenol formaldehyde resin) for comparison. Wherein the formula of rubber is refined according to the formula shown in Table 1, wherein the blending amount of each component is based on the rubber per 100 parts by weight (phr).

[0100] The formula of table 1 rubber composition

[0101] Compounding amount / phr Natural Rubber (NR) 100.00 Carbon black (N236) 60.00 Zinc oxide 7.00 stearic acid 0.50 Cobalt salt (CN20.5%, Shepherd company product) 0.75 Sulfur (80%, OT20) 5.00 N, N-dicyclohexyl-2-benzothiazole sulfenamide (DZ) 1.20 N-(1,3-Dimethylbutyl)-N’-phenyl-p-phenylenediamine (4020) 1.00 HMMM (65% pure, supported on silica) 3.50 The resin of embodiment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com