A kind of pdc cutter based on damping structure

A technology of cutting teeth and composite sheets, which is applied in the field of cutting teeth to achieve the effects of reducing impact force, improving impact resistance and life, and improving impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

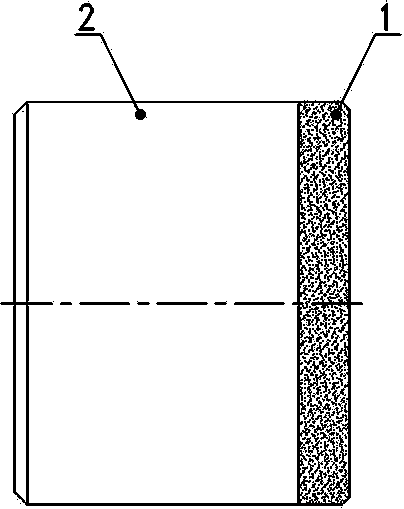

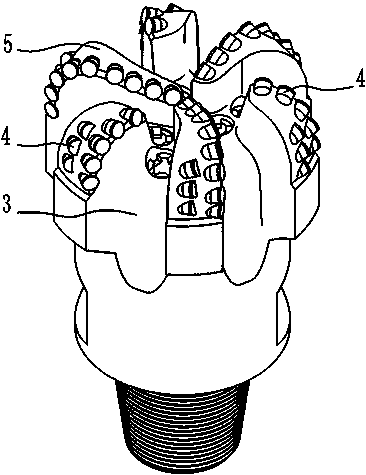

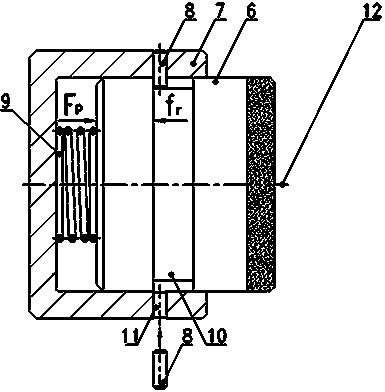

[0018] Such as figure 1 , figure 2 with image 3 Shown, a kind of PDC cutting tooth based on damping structure, it comprises PDC cutting tooth 4, and described PDC cutting tooth 4 is installed on the bit blade blade 5 of PDC bit 3, and described PDC cutting tooth 4 comprises movable PDC Composite sheet 6, bushing 7, limiter 8 and damper 9, a mounting hole is provided on the bushing 7, and the movable PDC composite sheet 6 is installed in the mounting hole. In this embodiment, the movable PDC composite sheet 6 is made up of polycrystalline diamond 1 and cemented carbide substrate 2, and polycrystalline diamond 1 is positioned at the front end of cemented carbide substrate 2, and described installation hole is circular blind hole, so when movable PDC composite sheet 6 receives During impact, the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com