Fiber-reinforced building formwork and preparation method thereof

A fiber-reinforced, building formwork technology, which is applied in the on-site preparation of building components, construction, building construction, etc., can solve the problems of residual aluminum formwork, short service life, low production efficiency, etc., and avoid breakage and corner damage. , The effect of improving the overall mechanical properties and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

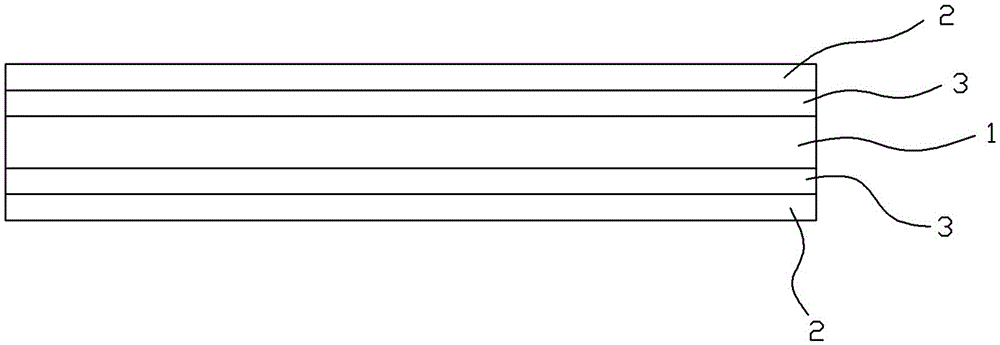

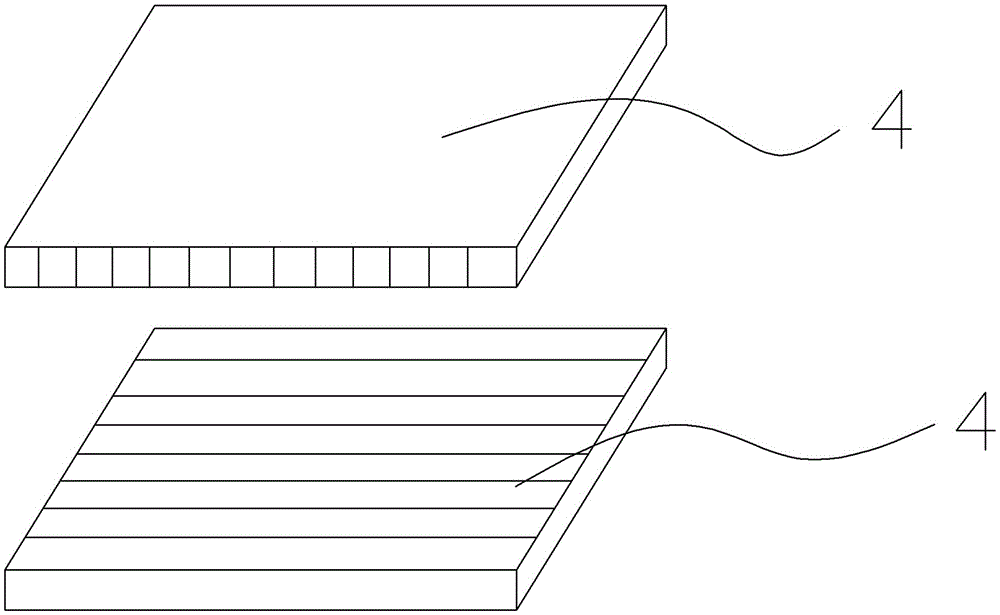

[0018] A method for preparing a fiber-reinforced building formwork, the steps are as follows:

[0019] (1) Preparation of board core: a. Rotary cut veneer, dry the veneer after rotary cutting at 60°C~110°C for 4h~8h, and the drying temperature is preferably 80°C~100°C; b. Apply glue to the veneer, The amount of glue applied to the veneer is 100g / m 2 ~500g / m 2, the adhesive used is coated with phenolic resin, urea-formaldehyde resin or melamine. After the glue is applied, the multi-layer veneer is laid as a whole, so that the wood fiber directions of adjacent veneers are perpendicular to each other to form the core 1, and then under 8MPa~20MPa pressure Next, cold press the board core 1 for 30min~2h, and the cold pressing pressure is preferably 10MPa~15MPa, which can promote the penetration of glue and increase the bonding force between the board cores; c. At a temperature of 70°C~140°C and a hot pressing pressure of 8MPa~20MPa The core 1 is then hot-pressed and cured, the hot...

Embodiment 1

[0021] In this embodiment, the veneer after rotary cutting was dried at 60°C for 8 hours, and melamine glue was applied on the veneer, and the amount of glue applied was 500g / m 2 , paving to form core 1 with a thickness of 15mm, cold pressing the formed core 1 with a pressure of 8MPa and a cold pressing time of 2h, followed by hot pressing at a temperature of 70°C and a pressure of 20MPa, hot-pressing time is 8min, pressurize once every 2min during the hot-pressing process; impregnate, pull and cool the alkali-free glass fiber under the copolymerized polypropylene with a melt index of 50g / 10min to obtain fiber-reinforced prepreg Material strips, based on the total weight of the fiber-reinforced prepreg sheets, the weight percentage of continuous fibers is 20wt%, and the obtained fiber-reinforced prepreg strips are cut into fiber-reinforced prepregs that match the size of the core 1 Material sheet layer, surface layer 2 is one layer, the thickness of the surface layer is 0.3mm,...

Embodiment 2

[0028] In this embodiment, the drying temperature of the veneer is set to 110°C, the drying time is set to 4h, the cold pressing pressure is set to 20MPa, the cold pressing time is set to 30min, the hot pressing temperature is set to 140°C, and the hot pressing pressure is set to 8MPa, the hot pressing time is set to 15min, based on the total weight of the fiber reinforced prepreg sheet, the weight percentage of the continuous fiber is 80wt%, the number of surface layers is 2 layers, and the thickness of the surface layer is 0.3mm. Embodiment 1 is the same. The building formwork in this embodiment was tested with a drop hammer. The drop hammer impacted 10 times, the weight of the drop hammer was 2kg, and the drop height was 1m. The measured static bending strength retention rate of the building template was 91%, and the static bending modulus retention rate was 93%. After boiling the building formwork in the present embodiment for 2 hours in a pressure cooker, it was cooled at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com