Luminous 3D printing photosensitive adhesive and preparation method thereof

A 3D printing and photosensitive adhesive technology, applied in luminescent coatings, coatings, additive processing, etc., can solve the problems of inability to achieve full color, heating, inconvenient use, etc., and achieve fast curing speed, simple process and mature technology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

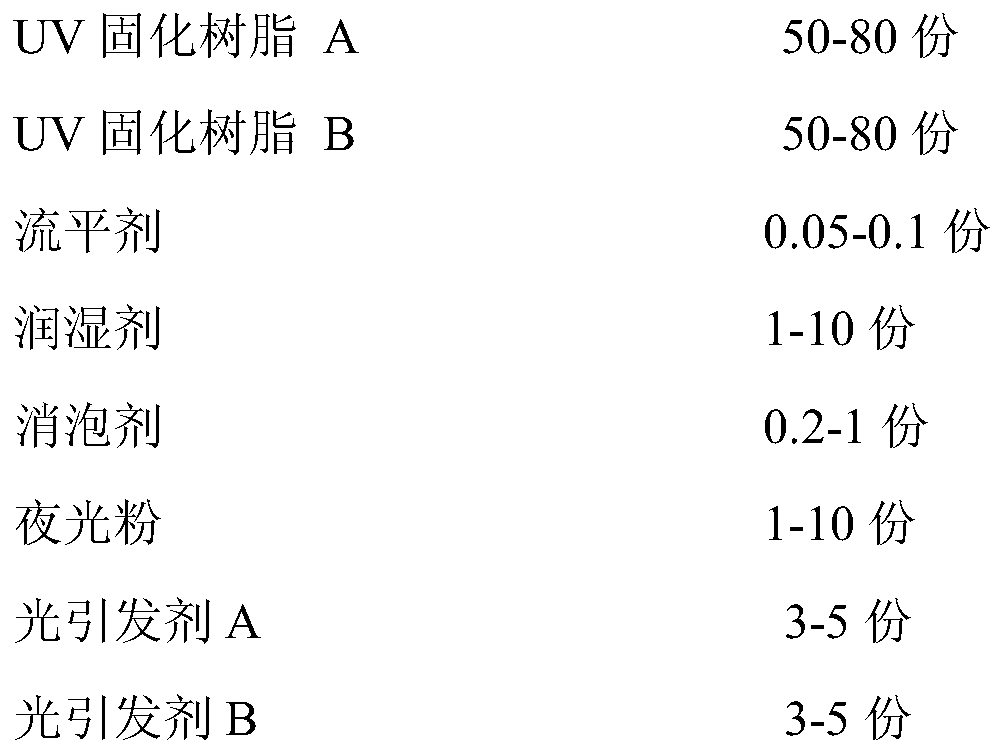

[0033] A luminous 3D printing photosensitive adhesive, calculated in parts by weight, its components and contents are as follows:

[0034]

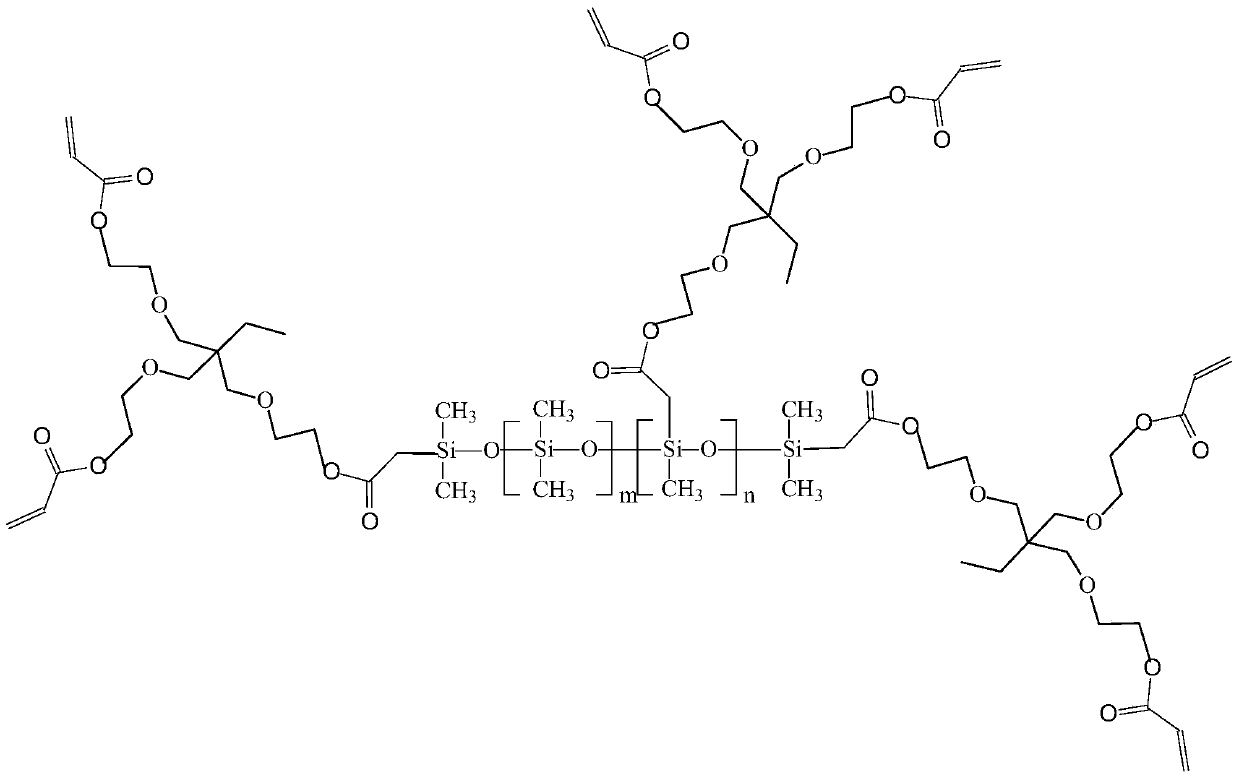

[0035] Wherein said UV curable resin A is prepared according to the following method:

[0036] Add 10g of methyl hydrogen-containing silicone oil and 10g of ethoxylated trimethylolpropane triacrylate into a 500ml three-necked flask, then add 0.01g of hydroquinone, pass in protective gas, stir and heat, and raise the temperature to 60 ℃, add 0.01g of chloroplatinic acid complex, keep the temperature under stirring for 3 hours, stop heating, wait until the temperature of the flask drops to room temperature, and obtain UV curable resin A.

[0037] Described UV curing resin B is a toughening resin, such as a mixture of epoxy acrylate and polyurethane acrylate in a mass ratio of 1:1;

[0038] The leveling agent is Tego Glide 410;

[0039] Described wetting agent is NP-100 of U.S. Dow Company;

[0040] The said luminous powder is the yell...

Embodiment 2

[0049] A luminous 3D printing photosensitive adhesive, calculated in parts by weight, its raw material composition and content are as follows:

[0050]

[0051] Wherein said UV curable resin A is prepared according to the following method:

[0052] Add 10g of methyl hydrogen-containing silicone oil and 10g of ethoxylated trimethylolpropane triacrylate into a 500ml three-necked flask, then add 0.01g of hydroquinone, pass in protective gas, stir and heat, and raise the temperature to 60 ℃, add 0.01g of chloroplatinic acid complex, keep the temperature under stirring for 3 hours, stop heating, wait until the temperature of the flask drops to room temperature, and obtain UV curable resin A.

[0053]Described UV curable resin B is the mixture of epoxy acrylate and polyurethane acrylate in a mass ratio of 2:1;

[0054] The leveling agent is a mixture of German BYK-345 and BYK-346 in a mass ratio of 1:1;

[0055] The wetting agent is German BYK 333;

[0056] The defoamer is a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com