A ball mill auxiliary co 2 Method for preparing oligolayer graphene by intercalation

A technology of oligolayer graphite and CO2, which is applied in the field of ball milling-assisted CO2 intercalation to prepare oligolayer graphene, can solve the problems of harsh reaction conditions, long reaction cycle, and unfriendly environment, and achieve easy large-scale production, shortened cleaning process, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of ball milling assisted CO2 intercalation prepares the method for oligolayer graphene, comprises the following steps:

[0034] (1) Add zirconia balls with a diameter of 3mm into a 100mL zirconia ball mill jar, so that the zirconia balls account for one-third of the volume of the zirconia ball mill jar;

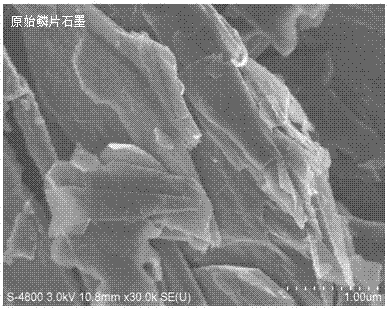

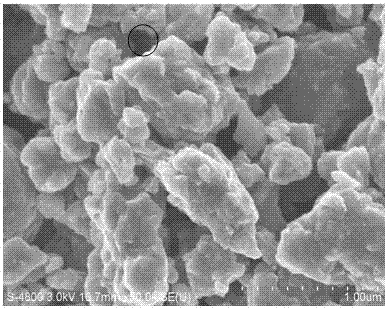

[0035] (2) Add 3 g of flake graphite with a particle size of 625 mesh to the zirconia ball mill jar, so that the mass ratio of flake graphite to ball milling balls is 1:10;

[0036] (3) Fix the zirconia ball mill jar to the planetary ball mill and mill at a speed of 400r / min for 8 hours to obtain the ball milled sample, and transfer the ball milled sample to the quartz kiln furniture;

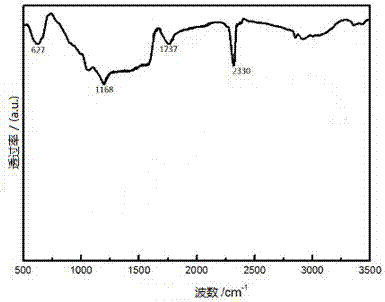

[0037] (4) Send the quartz kiln furniture into the middle of the atmosphere-protected CVD tube furnace, seal and vacuum the CVD tube furnace, and then continuously feed CO at a flow rate of 0.5L / min. 2 gas;

[0038] (5) Heating at a rate of 5°C / min, raising the temperature to 6...

Embodiment 2

[0048] A kind of ball milling assisted CO2 intercalation prepares the method for oligolayer graphene, comprises the following steps:

[0049] (1) Add polytetrafluoroethylene balls with a diameter of 3.5 mm into a 100mL polytetrafluoroethylene ball mill tank, so that the polytetrafluoroethylene balls account for one-third of the volume of the polytetrafluoroethylene ball mill tank;

[0050] (2) Add 3g of spherical graphite with a particle size of 400 mesh to the polytetrafluoroethylene ball mill tank, so that the mass ratio of spherical graphite to polytetrafluoroethylene balls is 1:20;

[0051] (3) Fix the polytetrafluoroethylene ball mill jar to the planetary ball mill and mill at a speed of 600r / min for 6 hours to obtain the ball milled sample, and transfer the ball milled sample to the alumina ceramic kiln furniture;

[0052] (4) Send the alumina ceramic kiln furniture into the middle of the atmosphere-protected CVD tube furnace, seal and vacuum the CVD tube furnace, and th...

Embodiment 3

[0056] A kind of ball milling assisted CO2 intercalation prepares the method for oligolayer graphene, comprises the following steps:

[0057] (1) Add agate balls with a diameter of 4mm into a 100mL agate ball mill jar, so that the agate balls account for one-third of the volume of the agate ball mill jar;

[0058] (2) Add 3g of expandable graphite with a particle size of 325 mesh to the agate ball mill jar, so that the mass ratio of expandable graphite to agate balls is 1:50;

[0059] (3) Fix the agate ball mill jar to the planetary ball mill and mill at a speed of 300r / min for 48 hours to obtain the ball milled sample, and transfer the ball milled sample to the quartz kiln furniture;

[0060] (4) Send the quartz kiln furniture into the middle of the atmosphere-protected CVD tube furnace, seal and vacuum the CVD tube furnace, and then continuously feed CO at a flow rate of 0.3L / min. 2 gas;

[0061] (5) Heating at a rate of 5 °C / min to 400 °C for 3 hours, and then cooling to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com