Lead-zinc smelting slag based geopolymer gelling material and preparation method thereof

A technology for polymer glue and smelting slag, applied in cement production and other directions, can solve problems such as less research, and achieve the effect of protecting the ecological environment, improving economic benefits and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

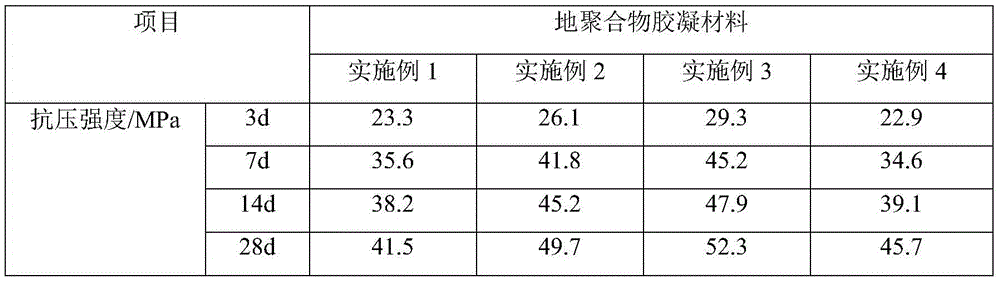

Examples

Embodiment 1

[0026] Embodiment 1: take lead-zinc smelting slag as main raw material geopolymer composition and its mass percentage content are: lead-zinc smelting slag 72wt.%, fly ash 5wt.%, composite alkali activator (sodium silicate and Sodium hydroxide is prepared by mixing 8wt.% of sodium hydroxide at a ratio of 1:1, 3wt.% of sulfate activator, 1wt.% of aluminate activator (sodium aluminate), and 11wt.% of deionized water.

[0027] The preparation steps of the above-mentioned lead-zinc smelting slag base polymer are as follows:

[0028] In the first step, the lead-zinc smelting slag and fly ash are dried separately until the moisture content is less than 1wt.%, and then placed in a ball mill for pre-grinding until the specific surface area is 400m 2 / kg or more, then mix well and add sulfate activator and aluminate activator to grind together until the specific surface area is 500m 2 / kg or more, the ball mill mixture is obtained. Dissolving the composite base activator in deionized ...

Embodiment 2

[0031] Embodiment 2: take the lead-zinc smelting slag as main raw material geopolymer composition and its mass percentage content are: lead-zinc smelting slag 65wt.%, fly ash 8wt.%, composite alkali activator (sodium silicate and Potassium hydroxide is mixed according to the ratio of substance ratio 1:2) 8wt.%, sulfate activator 6wt.%, aluminate activator (calcium aluminate) 1wt.%, deionized water 12wt.%.

[0032] The preparation steps of the above-mentioned lead-zinc smelting slag base polymer are as follows:

[0033] In the first step, the lead-zinc smelting slag and fly ash are dried separately until the moisture content is less than 1wt.%, and then placed in a ball mill for pre-grinding until the specific surface area is 400m 2 / kg or more, then mix well and add sulfate activator and aluminate activator to grind together until the specific surface area is 500m 2 / kg or more, the ball mill mixture is obtained. Dissolving the composite base activator in deionized water to ...

Embodiment 3

[0036] Embodiment 3: take lead-zinc smelting slag as main raw material geopolymer composition and its mass percentage content are: lead-zinc smelting slag 65wt.%, fly ash 10wt.%, composite alkali activator (sodium silicate and Calcium hydroxide is prepared by mixing (1:1) 10wt.%, sulfate activator 4wt.%, aluminate activator (potassium aluminate) 1wt.%, deionized water 10wt.%.

[0037] The preparation steps of the above-mentioned lead-zinc smelting slag base polymer are as follows:

[0038] In the first step, the lead-zinc smelting slag and fly ash are dried separately until the moisture content is less than 1wt.%, and then placed in a ball mill for pre-grinding until the specific surface area is 400m 2 / kg or more, then mix well and add sulfate activator and aluminate activator to grind together until the specific surface area is 500m 2 / kg or more, the ball mill mixture is obtained. Dissolving the composite base activator in deionized water to prepare a solution;

[0039] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com