A kind of boron-containing high-strength annealing-free fastener steel wire rod and its preparation method

A high-strength, fastener technology, applied in the field of materials, can solve the problems of plastic toughness and processing deformation ability that cannot meet the market demand, and achieve the effect of reducing processing procedures and steel consumption, improving the deformation ability of upsetting and increasing the strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the boron-containing high-strength annealing-free fastener steel wire rod according to the present invention is characterized in that it comprises the following steps:

[0026] A. Hot metal pretreatment desulfurization: the chemical composition C 4.5~5.0wt%, Si 0.30~0.50wt%, Mn 0.25~0.50wt%, P 0.090~0.110wt%, S≤0.020wt%, the rest is Fe and unavoidable The blast furnace molten iron with impurities is transported to the KR method molten iron pretreatment device for desulfurization treatment. The insertion depth of the stirring head is controlled at 2200~2400mm, according to 15.0~17.0kg / t 钢 Add the conventional CaO-based desulfurizer for desulfurization treatment, and control the stirring time to 8 minutes; after the stirring, carry out the slag removal operation to ensure that the molten iron surface in the ladle is exposed ≥ 4 / 5, and remove the desulfurization slag; the molten iron composition after pretreatment The control is: C 4.5~4.8wt%, Si ...

Embodiment 1

[0053] A. Hot metal pretreatment desulfurization: blast furnace hot metal (chemical composition C 4.5wt%, Si 0.30wt%, Mn 0.25wt%, P0.090wt%, S 0.012wt%, the rest is Fe and unavoidable impurities) transport To the KR method molten iron pretreatment device for desulfurization treatment, the insertion depth of the stirring head is controlled at 2200-2400mm, according to 15.0kg / t 钢 Add the conventional CaO-based desulfurizer for desulfurization treatment, and control the stirring time to 8 minutes; after the stirring, carry out the slag removal operation to ensure that the molten iron surface in the ladle is exposed ≥ 4 / 5, and remove the desulfurization slag; the molten iron composition after pretreatment The control is: C 4.5wt%, Si 0.30wt%, Mn 0.25wt%, P0.090wt%, S 0.002wt%, the rest is Fe and unavoidable impurities.

[0054] B, molten steel smelting: the pretreatment deep desulfurization hot metal of step A (chemical composition C 4.5wt%, Si 0.30wt%, Mn0.25wt%, P 0.090wt%, S 0....

Embodiment 2

[0067] A, hot metal pretreatment desulfurization: blast furnace hot metal (chemical composition C 4.8wt%, Si 0.40wt%, Mn 0.38wt%, P0.102wt%, S 0.017wt%, the rest is Fe and unavoidable impurities) transport To the KR method molten iron pretreatment device for desulfurization treatment, the insertion depth of the stirring head is controlled at 2200-2400mm, according to 16.0kg / t 钢 Add the conventional CaO-based desulfurizer for desulfurization treatment, and control the stirring time to 8 minutes; after the stirring, carry out the slag removal operation to ensure that the molten iron surface in the ladle is exposed ≥ 4 / 5, and remove the desulfurization slag; the molten iron composition after pretreatment The control is: C 4.6wt%, Si 0.40wt%, Mn 0.38wt%, P0.102wt%, S 0.003wt%, the rest is Fe and unavoidable impurities.

[0068] B, molten steel smelting: the pretreatment deep desulfurization hot metal of step A (chemical composition C 4.6wt%, Si 0.40wt%, Mn0.38wt%, P 0.102wt%, S 0....

PUM

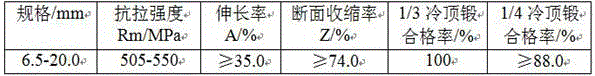

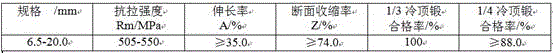

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com