Preparation method of polylactic-acid-gel-toughened sponge

A polylactic acid and polyurethane sponge technology, applied in the field of fabric accessories, can solve the problems of high cost and large usage of sponges, and achieve the effects of improving hydrophilicity, increasing hydrophilic groups and improving rebound rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

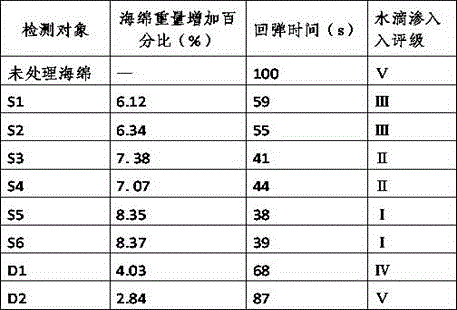

Examples

Embodiment 1

[0025] The preparation method of the polylactic acid gel toughened sponge of embodiment 1, comprises steps:

[0026] S1: Put the polyurethane sponge in the alkali pretreatment solution for immersion treatment, heat up the pretreatment for 2 hours, wash it with water, dry it, put the polyurethane sponge in low-temperature oxygen for plasma treatment, apply a voltage discharge frequency of 13.75MHz, and a power of 100W. The time is 20s;

[0027] S2: Configure polylactic acid finishing solution. The main components of polylactic acid finishing solution are ethylenediamine-modified polylactic acid, ethyl lactate and carbodiimide. The weight percentage of ethylenediamine-modified polylactic acid in the polylactic acid finishing solution is 3%, the weight ratio of carbodiimide to ethylenediamine-modified polylactic acid is 0.03:1;

[0028] S3: Soak the polyurethane sponge in the polylactic acid finishing solution for at least two padding treatments, remove the excess solution, rais...

Embodiment 2

[0032] Embodiment 2 is based on embodiment 1, difference is:

[0033] S1: Put the polyurethane sponge in the alkali pretreatment solution for immersion treatment, heat up the pretreatment for 5 hours, wash it with water, dry it, put the polyurethane sponge in low-temperature oxygen for plasma treatment, apply a voltage discharge frequency of 13.75MHz, and a power of 150W. The time is 50s;

[0034] S2: Configure polylactic acid finishing solution. The main components of polylactic acid finishing solution are ethylenediamine-modified polylactic acid, ethyl lactate and carbodiimide. The weight percentage of ethylenediamine-modified polylactic acid in the polylactic acid finishing solution is 7%, the weight ratio of carbodiimide to ethylenediamine-modified polylactic acid is 0.1:1;

[0035] S3: Soak the polyurethane sponge in the polylactic acid finishing solution for at least two padding treatments, roll off the excess solution, raise the temperature of the sponge to 70°C, and k...

Embodiment 3

[0039] Embodiment 3 is based on embodiment 2, difference is:

[0040] S1: Put the polyurethane sponge in the alkali pretreatment solution for immersion treatment, heat up the pretreatment for 3.5 hours, wash with water, dry, put the polyurethane sponge in low-temperature oxygen for plasma treatment, apply the voltage discharge frequency of 13.75MHz, and the power of 125W, The processing time is 35s;

[0041] S2: Configure polylactic acid finishing solution. The main components of polylactic acid finishing solution are ethylenediamine-modified polylactic acid, ethyl lactate and carbodiimide. The weight percentage of ethylenediamine-modified polylactic acid in the polylactic acid finishing solution is 5%, the weight ratio of carbodiimide to ethylenediamine-modified polylactic acid is 0.065:1;

[0042] S3: Soak the polyurethane sponge in the polylactic acid finishing solution for at least two padding treatments, roll off the excess solution, raise the temperature of the sponge t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com