Graphene oxide-modified electrode material for energy storage flow battery

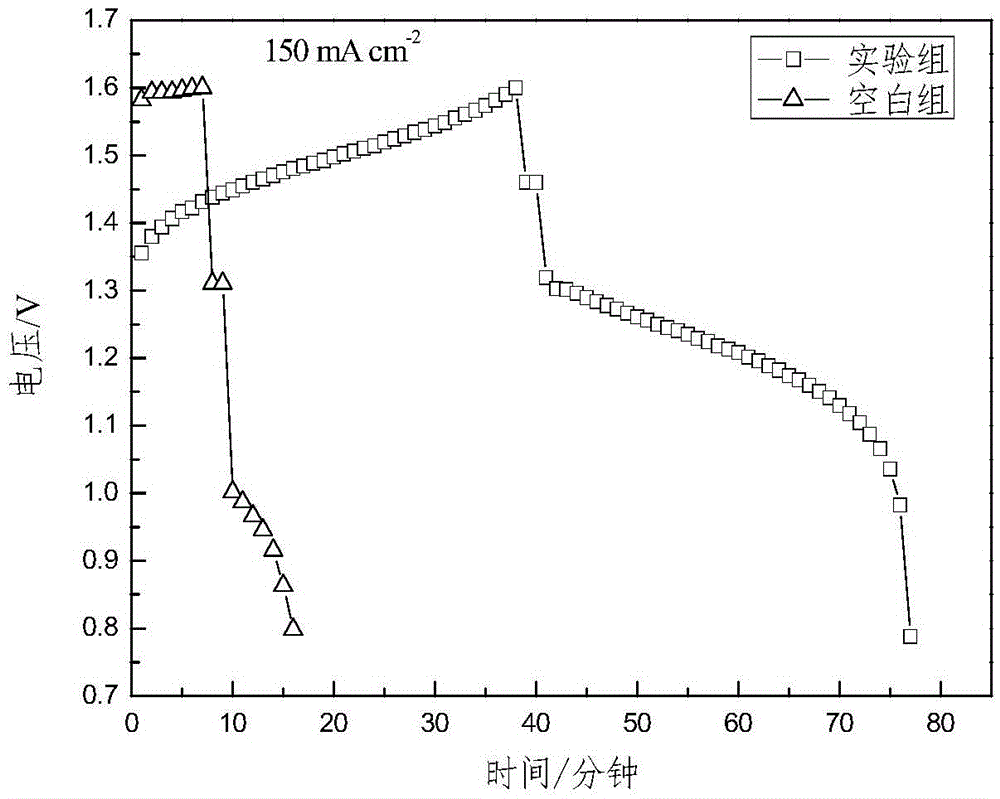

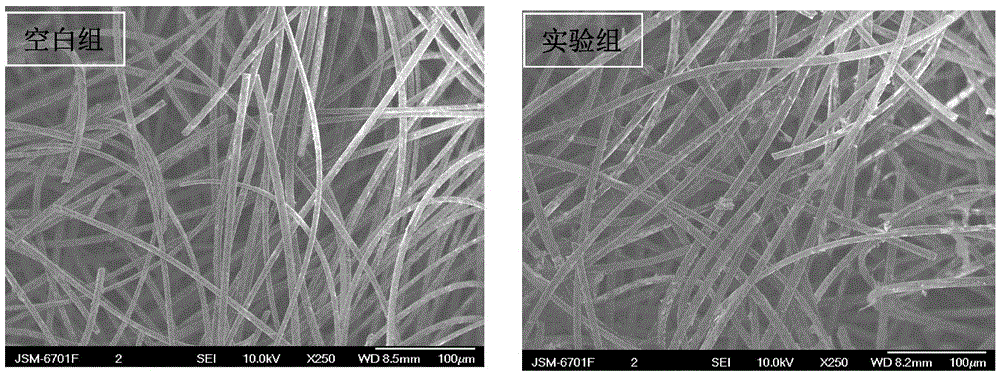

An electrode material, the technology of all-vanadium redox flow battery, applied in the direction of battery electrodes, fuel cells, regenerative fuel cells, etc., can solve the problems of unstable adhesion, consume a lot of manpower and material resources, reduce charge transfer impedance, etc., and achieve omission of processing and time, save equipment and capital investment, and enrich the effect of oxygen-containing functional groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

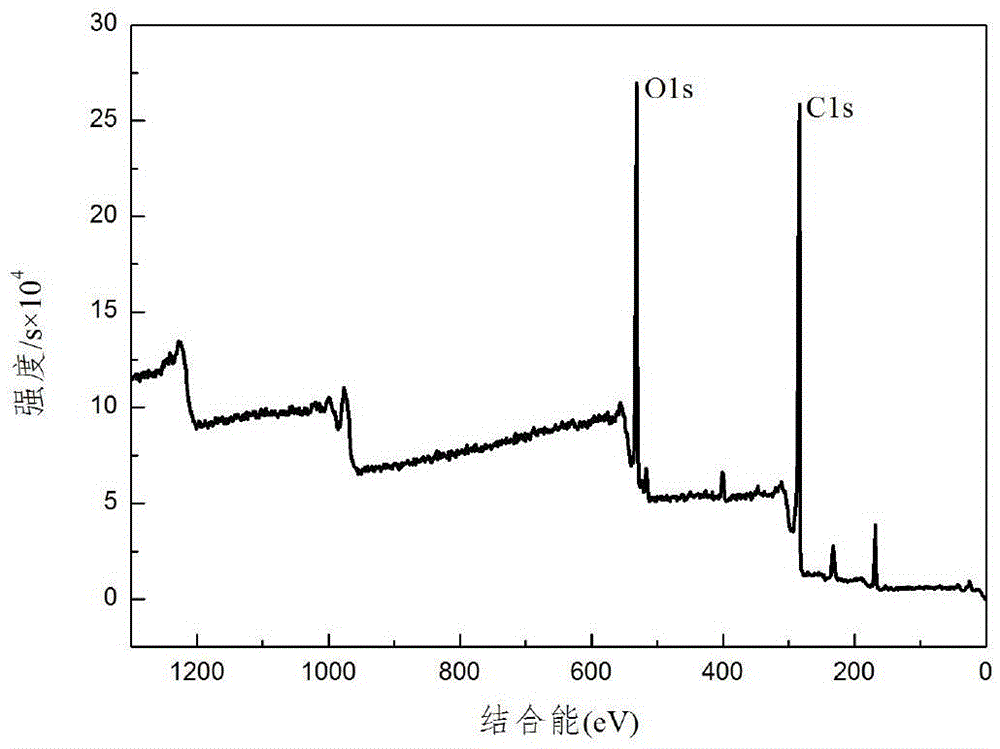

Embodiment 1

[0030] Take 0.3g of graphite powder with a purity of 99.9999%, 2g of potassium permanganate, 36ml of concentrated sulfuric acid, and 4ml of concentrated phosphoric acid, put them into a round-bottomed flask, mix the three fully, place the round-bottomed flask in a magnetic stirring pot, and put it in an oil bath. Set the temperature to 45°C and the reaction time to 24 hours, place the prepared graphene oxide in ice water, ensure that the temperature of the ice-water bath is 1°C, add 33% hydrogen peroxide to the graphene oxide until no bubbles are generated in the solution, Take the solution from the previous step and put it into a 50ml centrifuge tube, add 30ml, 2mol / L hydrochloric acid solution, centrifuge for 15min at a speed of 2000r / min, wash three times, take the clear liquid and add deionized water, centrifuge for 15min and wash at a speed of 6000r / min , until the pH of the solution is 6, a graphene oxide precipitate is obtained, containing hydroxyl, carboxyl, epoxy, and ...

Embodiment 2

[0033] Take 1.5g of graphite powder with a purity of 99.9999%, 10g of potassium permanganate, 1g of sodium nitrate, 180ml of concentrated sulfuric acid, and 20ml of concentrated phosphoric acid, put them into a round-bottomed flask, mix them well, and place the round-bottomed flask in a magnetic stirring pot , oil bath, set the temperature to 50°C, and the reaction time is 30 hours, place the prepared graphene oxide in ice water, ensure that the temperature of the ice-water bath is 3°C, add 33% hydrogen peroxide to the graphene oxide until it is in the solution No bubbles are generated, take the solution from the previous step and put it into a 50ml centrifuge tube, add 30ml, 2mol / L hydrochloric acid solution, centrifuge for 15min at a speed of 3000r / min, wash three times, take the clear solution and add deionized water, centrifuge and wash for 30min, The rotating speed is 7000r / min until the pH of the solution is 6, and the graphene oxide precipitate is obtained, which contain...

Embodiment 3

[0036] Take 1.5g of graphite powder with a purity of 99.9999%, 15g of potassium permanganate, 1g of potassium persulfate, 180ml of concentrated sulfuric acid, and 20ml of concentrated phosphoric acid, put them into a round-bottomed flask, mix them well, and place the round-bottomed flask in a magnetic stirring pot In an oil bath, the set temperature is 55°C, and the reaction time is 26 hours. The prepared graphene oxide is placed in ice water to ensure that the temperature of the ice-water bath is 5°C, and 33% hydrogen peroxide is added to the graphene oxide until the solution is If there is no bubbles in the medium, take the solution from the previous step and put it into a 50ml centrifuge tube, add 30ml, 2mol / L hydrochloric acid solution, centrifuge for 45min at a speed of 4000r / min, wash three times, take the clear solution and add deionized water, centrifuge and wash for 30min , rotation speed 8000r / min, until the pH of the solution is 7, graphene oxide precipitates are obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com