One-step synthesis method of polyethyleneimine

A polyethylene imine and synthesis method technology, applied in the field of polyethylene imine preparation, can solve the problems of unfavorable cost reduction, and achieve the effects of saving reaction time, avoiding high reactivity, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

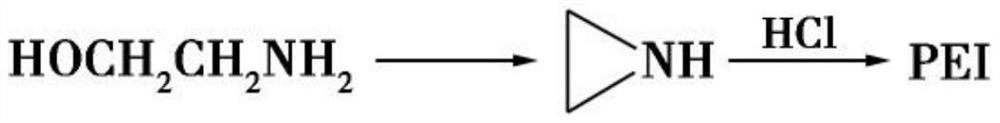

Method used

Image

Examples

Embodiment 1

[0049] Example 1 Without separation and purification of monomers, the hydrochloric acid method synthesizes PEI in one step

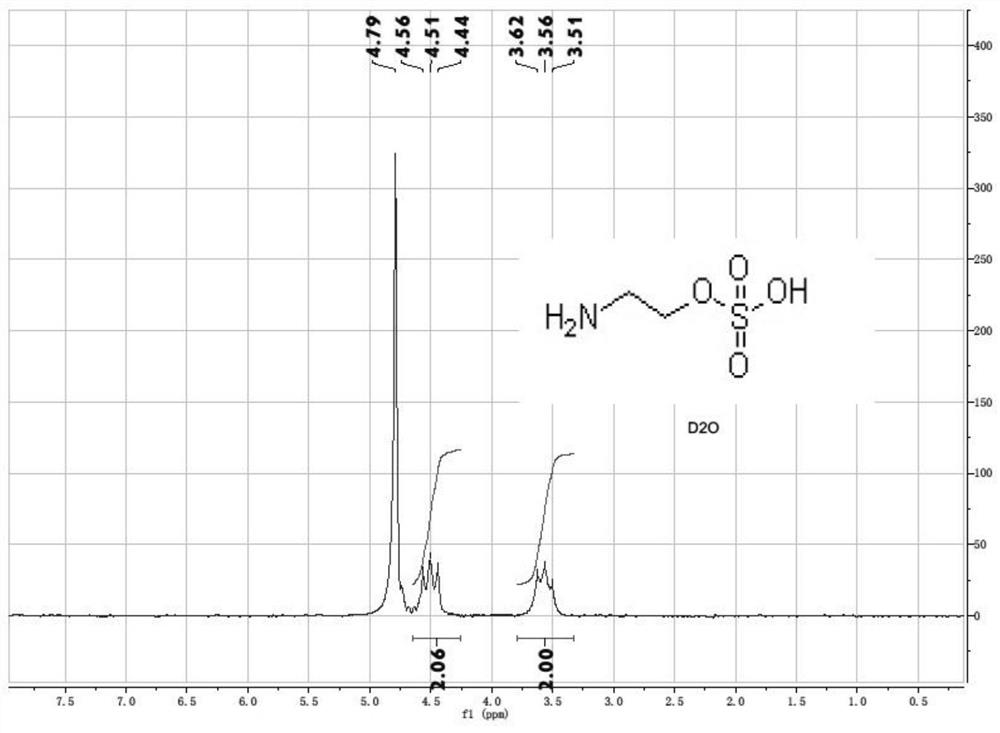

[0050] 1. Synthesis of aminoethanol hydrogen sulfate

[0051] The reaction formula is shown in formula 5:

[0052]

[0053] Concrete reaction steps are as follows:

[0054] 1) Take 30g of ice water and add it to a beaker, place it in an ice-salt bath, keep the temperature at 4°C, stir and slowly add 60g of concentrated sulfuric acid;

[0055] 2) According to the molar ratio of sulfuric acid to 1:1, slowly add 36.6g of ethanolamine dropwise to the solution, and at the same time add ice cubes to the solution continuously, and control the solution temperature at 5-7°C for about 1 hour;

[0056] 3) After the dropwise addition is completed, transfer the reaction solution to a three-necked flask, and carry out vacuum distillation in an oil bath. The distillation temperature is initially set to 135°C, and most of the liquid is evaporated; then slowly rise ...

Embodiment 2

[0079] Embodiment 2: One-step synthesis of PEI by 1,2 dichloroethane method

[0080] Take 30 g of ice water and add it to a 500 ml three-neck flask, place it in an ice-salt bath at 4°C, stir and slowly add 100 g of concentrated sulfuric acid; slowly add 61 g of ethanolamine dropwise to the solution, while continuously adding ice cubes to the solution, The solution temperature was controlled at 20°C.

[0081] After the dropwise addition is completed, carry out vacuum distillation in the oil bath. The distillation temperature is initially set to 135°C, and most of the liquid is evaporated; then the temperature is slowly raised to 160°C, and part of the liquid is evaporated, and the solution appears cloudy at the same time. The internal temperature of the solution was 150°C. Stop heating immediately and take the three-necked flask out of the oil bath, and place it in the air to cool naturally. A white solid precipitated out, and stood for several hours until the liquid completely...

Embodiment 3

[0085] Embodiment 3: Epichlorohydrin method one-step synthetic PEI

[0086] Take 100g of ice water and add it to a 2-liter three-neck flask, place it in a 4°C ice-salt bath, stir and slowly add 400g of 98% concentrated sulfuric acid; slowly add 244g of ethanolamine dropwise to the solution, and continuously add Ice cubes, the solution temperature was controlled at 20°C.

[0087] After the dropwise addition is completed, carry out vacuum distillation in the oil bath. The distillation temperature is initially set to 135°C, and most of the liquid is evaporated; then the temperature is slowly raised to 160°C, and part of the liquid is evaporated, and the solution appears cloudy at the same time. The internal temperature of the solution is 150°C. Stop heating immediately and take the three-neck flask out of the oil bath, and place it in the air to cool naturally. A white solid precipitates out. Leave it for several hours until the liquid completely becomes a white solid;

[0088] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com