Surface treatment method for alloy steel W18Cr4V mold parts

A surface treatment, alloy steel technology, applied in the field of surface technology improvement of alloy steel W18Cr4V mold parts, can solve the problems of poor working conditions, difficult quality control, no promotion or ban, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

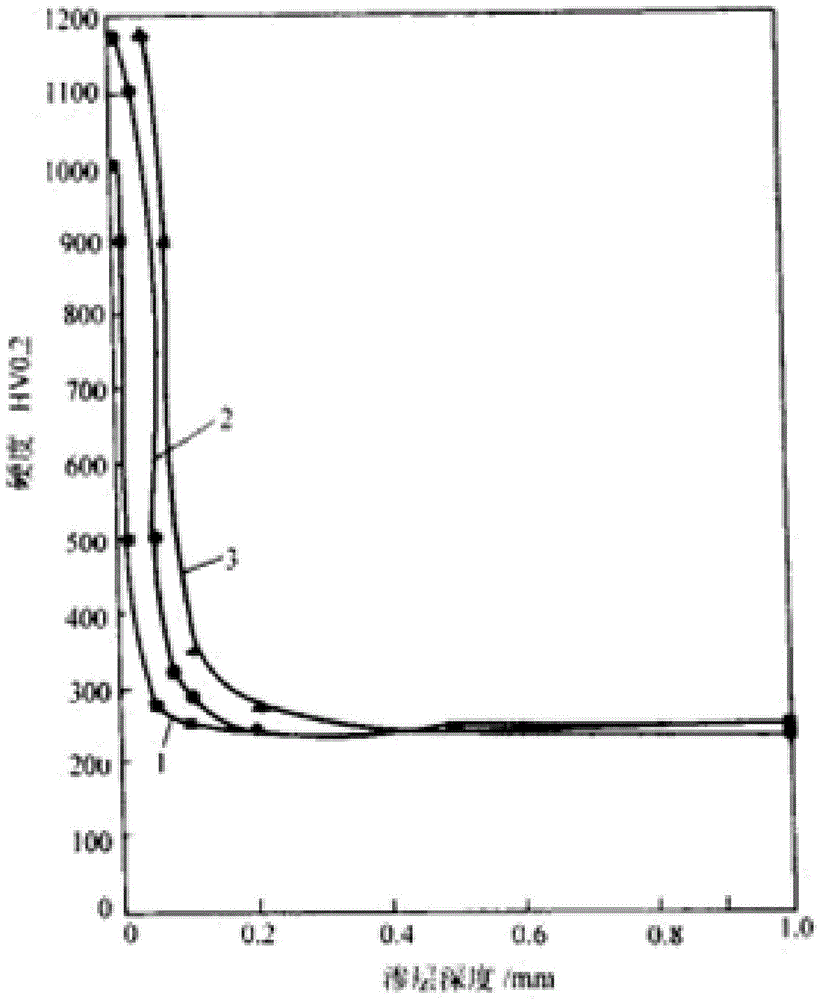

[0037] Concrete embodiment: a kind of surface treatment method of alloy steel W18Cr4V mold part, specifically comprises: workpiece cleaning, after workpiece cleaning, puts into furnace immediately within 3-5 seconds, deflates, heats, cools; Described degassing stage, ammonia and The carrier gas is 50% each; in the heating stage, the nitriding temperature reaches 400-500°C and is maintained for 5 hours, the ammonia decomposition rate is 35-40%, and the working temperature of the heating furnace does not exceed 700°C. After gas nitriding treatment, the nitriding depth is 0.05-0.07mm, and the hardness is 900-1200HV.

[0038] After gas nitriding of W18Cr4V mold parts, the hardness distribution curves of the nitriding layer at 400°C, 450°C and 500°C are as follows figure 1 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com