Quick charging lithium-ion battery

A lithium-ion battery, fast charging technology, applied to battery electrodes, secondary batteries, circuits, etc., can solve the problems of long charging cycle, environmental pollution, etc., and achieve the effects of smooth surface, high electrochemical activity, and favorable cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

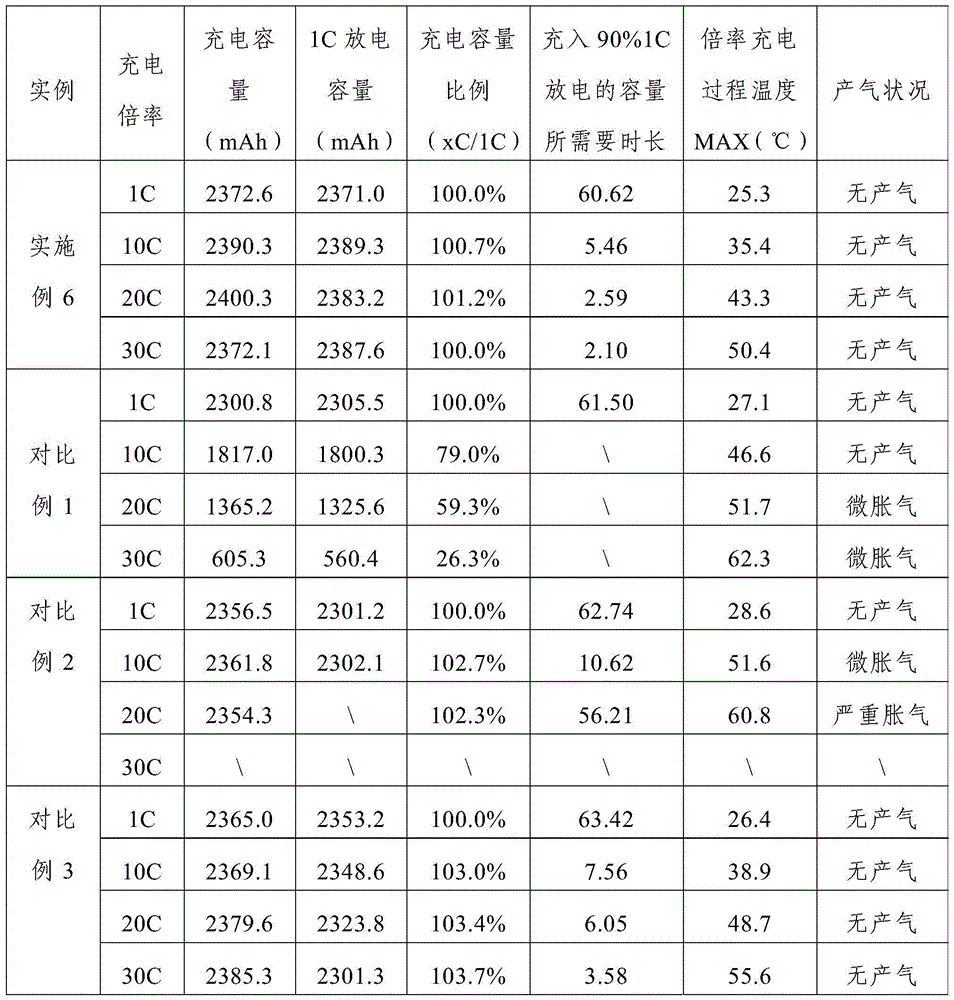

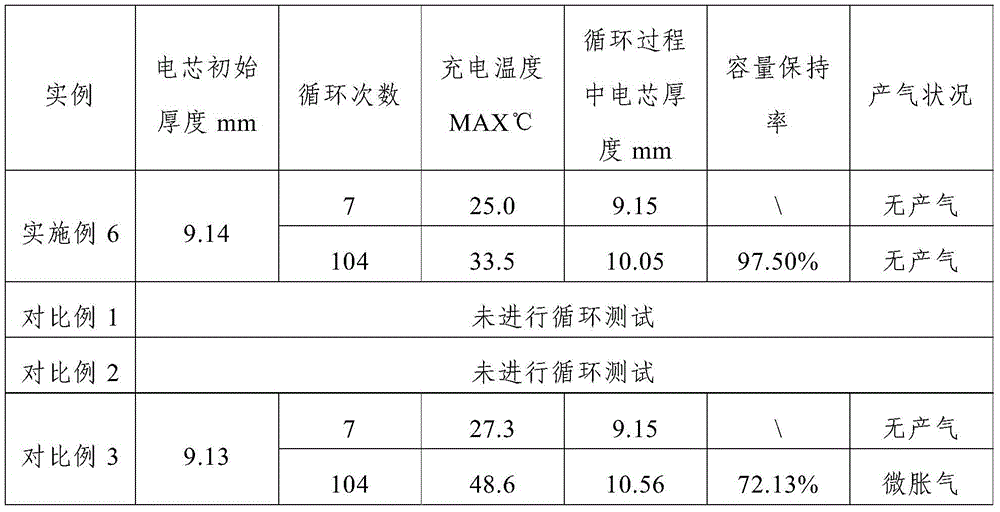

Examples

Embodiment 1

[0028] Preparation of modified graphite:

[0029] Step 1: Melt the asphalt powder under the protection of nitrogen atmosphere, and then spin the melted asphalt powder centrifugal spinning under the action of a 1.5T magnetic field to obtain asphalt filaments; the melting temperature is 400°C;

[0030] Step 2. Cut the pitch thread described in Step 1 into pitch particles with a length of 20 μm, and then carbonize the pitch particles under the protection of a nitrogen atmosphere to obtain primary particle carbon fibers; the temperature of the carbonization treatment is 1000°C, The carbonization treatment time is 8h;

[0031] Step 3. Heat the phenolic resin powder at 400°C for 5.5 hours, then heat up to 600°C in a nitrogen atmosphere, then change the nitrogen atmosphere to carbon dioxide, heat and activate for 40 minutes, and get activated phenolic resin after natural cooling;

[0032] Step 4. Mix the phenolic resin particles, the primary particle carbon fibers described in step 2 and the...

Embodiment 2

[0035] Preparation of modified graphite:

[0036] Step 1: Melt the asphalt powder under the protection of nitrogen atmosphere, and then spin the melted asphalt powder centrifugal spinning under the action of a 1T magnetic field to obtain asphalt filaments; the melting temperature is 300°C;

[0037] Step 2. Cut the pitch thread described in Step 1 into pitch particles with a length of 30 μm, and then carbonize the pitch particles under the protection of a nitrogen atmosphere to obtain primary particle carbon fibers; the temperature of the carbonization treatment is 1100°C, The carbonization treatment time is 7h;

[0038] Step 3. Heat the phenolic resin powder at 500°C for 5 hours, then heat up to 600°C in a nitrogen atmosphere, then change the nitrogen atmosphere to carbon dioxide, heat and activate for 60 minutes, and obtain an activated phenolic resin after natural cooling;

[0039] Step 4. Mix the phenolic resin particles, the primary particle carbon fibers described in step 2 and t...

Embodiment 3

[0042] Preparation of modified graphite:

[0043] Step 1: Melt the asphalt powder under the protection of nitrogen atmosphere, and then spin the melted asphalt powder centrifugally under the action of a 1.2T magnetic field to obtain asphalt filaments; the melting temperature is 500°C;

[0044] Step 2. Cut the pitch thread described in Step 1 into pitch particles with a length of 5 μm, and then carbonize the pitch particles under the protection of a nitrogen atmosphere to obtain primary particle carbon fibers; the temperature of the carbonization treatment is 1200°C, The carbonization treatment time is 6h;

[0045] Step 3. Heat the phenolic resin powder at 300°C for 6 hours, then heat up to 600°C in a nitrogen atmosphere, then change the nitrogen atmosphere to carbon dioxide, heat and activate for 30 minutes, and obtain activated phenolic resin after natural cooling;

[0046] Step 4. Mix the phenolic resin particles, the primary particle carbon fiber described in step 2 and the activat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com