Method for selectively increasing haloacid dehalogenase yield

A haloacid dehalogenase and selective technology, applied in the field of selectively improving the production of L-2-haloacid dehalogenase by Pseudomonas, can solve the problem of low yield and avoid uncertainty performance, increase output, and maintain stable output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Seed solution preparation:

[0017] (1) The symbiotic Pseudomonas sp. DEH138 (Pseudomonassp. DEH138) used in the present invention is stored in the China Industrial Microorganism Culture Collection and Management Center, and the number is CICC10431.

[0018] (2) Preparation of inorganic salt basal medium: Na 2 HPO 4 12H 2 O(12g / L),NaH 2 PO 4 2H 2 O (1g / L), NaCl (30g / L), yeast extract powder (0.1g / L), (NH 4 ) 2 SO 4 (2.0g / L), MgSO 4 ·7H 2 O (0.1g / L), the balance is water, adjust the pH to 7.0-7.5.

[0019] (3) 2-chloropropionic acid solid medium: add 0.04g / L bromothymol blue (as a pH indicator) to the inorganic salt basic medium, the final concentration is 18g / L agar, the final concentration is 8-20mmol / L of 2-chloropropionic acid.

[0020] (4) 2-chloropropionic acid liquid medium: add 2-chloropropionic acid at a final concentration of 8-20 mmol / L to the inorganic salt basal medium.

[0021] (5) 2216E medium: 5.0g / L, yeast extract powder 1.0g / L, FeCl30.1g / L,...

Embodiment 2

[0024] Effects of auxiliary carbon source and inducer types and culture methods on the production of dehalogenase:

[0025](1) The control in this example is the L-DEX obtained under normal culture conditions (2-chloropropionic acid as the only carbon source (2-chloropropionic acid liquid medium) cultured DEH13840~50h, OD600nm reached 0.4~0.6) The output of D-DEX is 2.46U and 0.21U respectively.

[0026] (2) DEH138 was cultured with 10mM glycolic acid, lactic acid, hydroxybutyric acid or glucose as the sole carbon source (respectively replacing 2-chloropropionic acid in 2-chloropropionic acid liquid medium), and the obtained bacteria had no dehalogenase activity .

[0027] (3) With 10mM iodoacetic acid, 2-fluoropropionic acid, 3-chloropropionic acid, 2-chlorobutyric acid, 2-bromobutyric acid, 2,2-dichloropropionic acid, 2-chloropropionamide or 2- When DEH138 was cultured with bromopropionamide as the only carbon source (respectively replacing 2-chloropropionic acid in 2-chlo...

Embodiment 3

[0046] Effects of lactic acid concentration and culture time on dehalogenase production:

[0047] (1) 10mM lactic acid, 10mM 2-chlorobutyric acid culture DEH13810h, 30h, 40h, 50h, 60h.

[0048] (2) 20mM lactic acid, 10mM 2-chlorobutyric acid culture DEH13810h, 30h, 40h, 50h, 60h.

[0049] (3) 30mM lactic acid, 10mM 2-chlorobutyric acid culture DEH13810h, 30h, 40h, 50h, 60h.

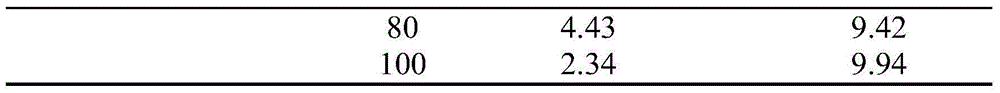

[0050] (4) As a result, the highest yield of L-DEX was 12.45U, which was 5.1 times that of 2-chloropropionic acid as the sole carbon source (the control in Example 2), and the highest yield of D-DEX was 0.16U, which remained stable , the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com