Diamond-ene artificial joint and production method thereof

An artificial joint, diamond olefin technology, applied in pharmaceutical formulations, medical science, tissue regeneration, etc., can solve the problem of low hardness and wear resistance of ultra-high molecular weight polyethylene, shortening the service life of artificial joint implants, and poor soft tissue organisms. Chemical reaction and other problems, to achieve the effect of improving lubricity, improving biocompatibility, and narrowing the particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

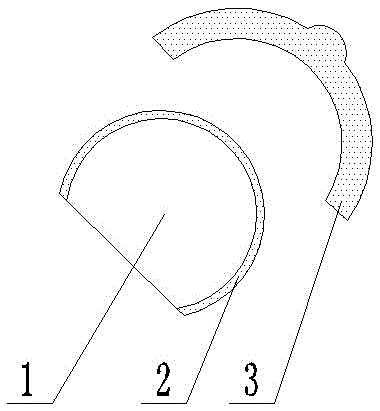

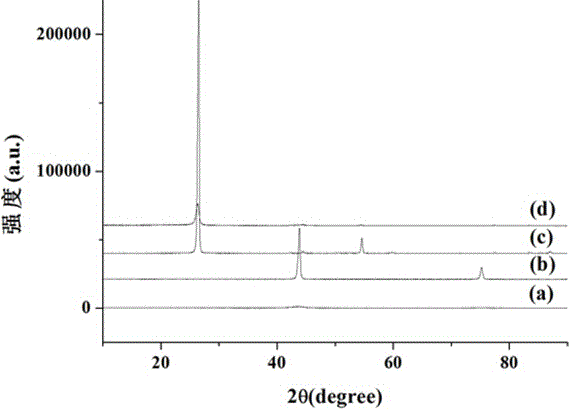

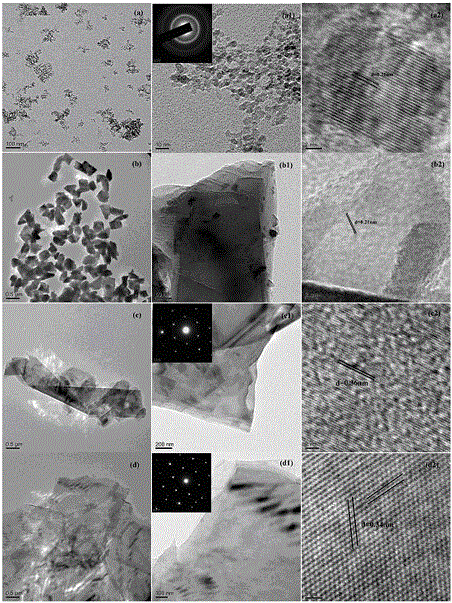

[0024] Diamondene artificial joints, such as figure 1 As shown, it includes a joint head and a joint socket 3 that cooperate with each other. The joint head includes a metal substrate 1, and an ultrafine diamondene layer 2 is arranged on the outside of the metal substrate 1. The ultrafine diamondene layer 2 is composed of nanodiamondene; the joint socket 3 is composed of Nanodiamantene and polyethylene, wherein the volume ratio of nanodiamantene and polyethylene is 2:3; the surface roughness of the articular fossa 3 is 0.09 microns; nanodiamantene is a lamellar single crystal structure, and nanodiamantene is Carbon atoms in the same layer are connected by sp3 orbital hybrid carbon bonds between carbon atoms in the same layer, and carbon atoms between layers are connected by sp2 hybrid carbon bonds; the crystal lattice of nanodiamondene The spacing is 0.21nm; the average particle size of nano-diamantene is R, 20≤R≤500nm; the C content of nano-diamantene is 99-100%. The ultrafi...

Embodiment 2

[0029] The difference between this embodiment and Example 1 is that the volume ratio of nano-diamondene to polyethylene in the articular fossa is 2:3, the surface roughness of the articular fossa is 0.08 micron, and the thickness of the ultrafine diamondene layer in the articular head is 2. The average particle diameter R of the nanodiamondene in the ultrafine diamondene layer is 30nm.

Embodiment 3

[0031] The difference between this embodiment and Example 1 is that the volume ratio of nanodiamondene and polyethylene in the articular fossa is 1:1, the surface roughness of the articular fossa is 0.06 microns, and the thickness of the ultrafine diamondene layer in the joint head is 1.5 The average particle size R of the nanodiamondene in the ultrafine diamondene layer is 20nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com