Method for manufacturing Ni steel moderately-thick plate for low-temperature container

A technology of low temperature container and manufacturing method, which is applied in the field of manufacturing 3.5Ni steel medium and thick plate for low temperature container, can solve the problems of unmentioned low temperature toughness, can not use LEG storage tank, higher than -110 ℃, etc., and can improve the low temperature Toughness and strength, simple heat treatment process, effect of reducing alloy cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

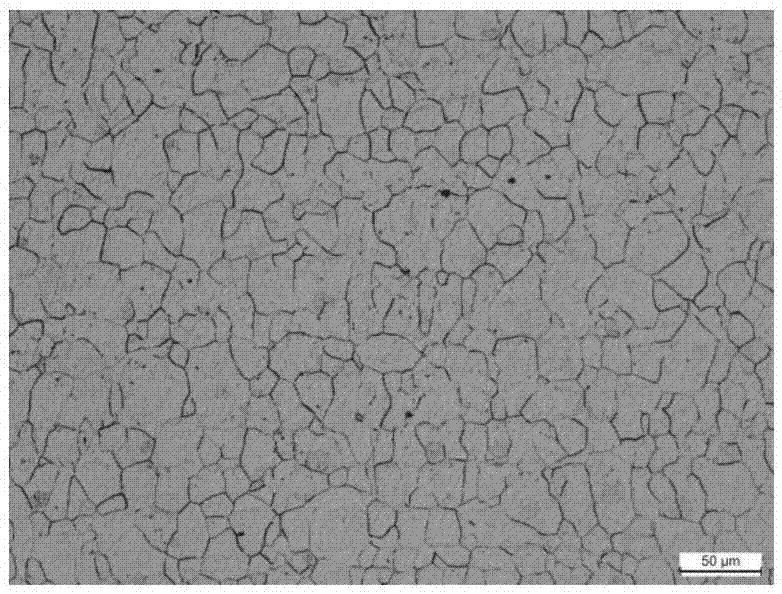

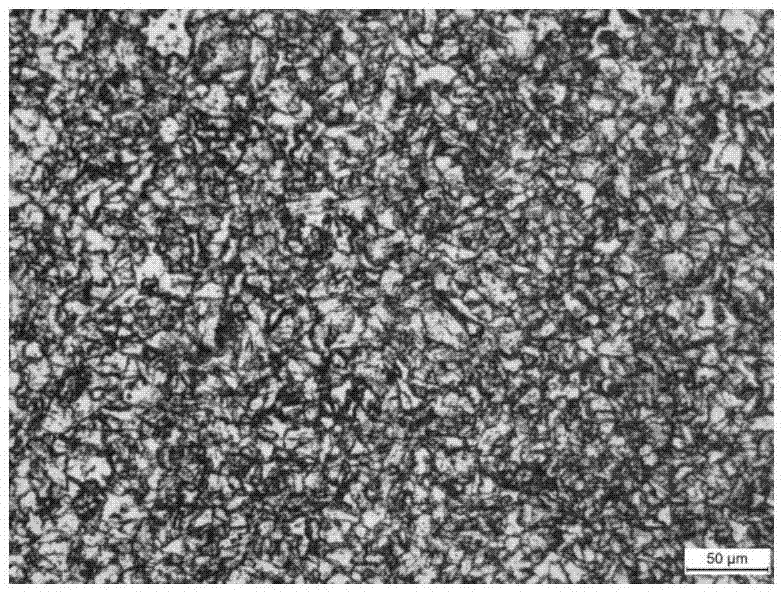

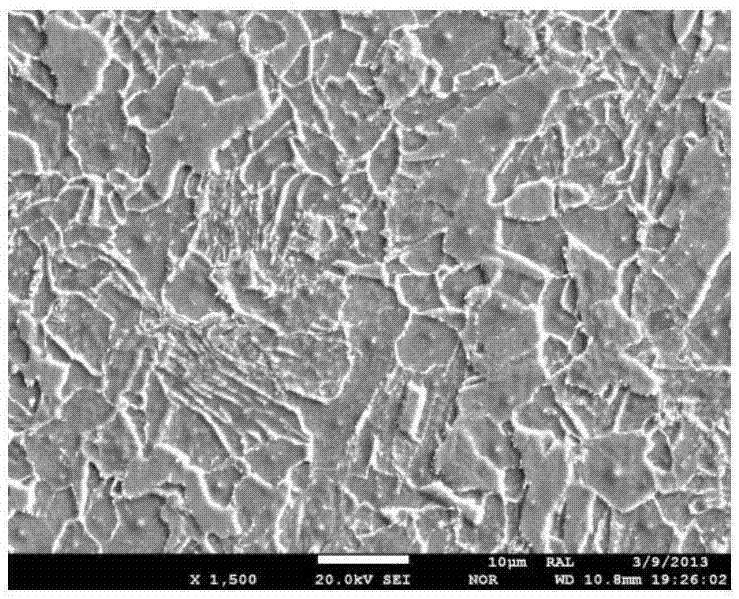

[0022] This embodiment provides a method for manufacturing a 3.5Ni steel plate for low-temperature vessels. A steel plate with a thickness of 15 mm is produced by rolling a billet with a thickness of 150 mm in a steel coil rolling mill. Including the following steps:

[0023] The composition of medium and thick plates is as follows: C: 0.055%, Si: 0.21%, Mn: 0.62, S: 0.002%, P: 0.005%, Ni: 3.46%, Alt: 0.031%, and the balance is Fe and Impurities; steelmaking according to the composition and continuous casting into a 150mm thick slab, the continuous casting slab is heated to 1200°C in a heating furnace, and kept for 2 hours; rolling is controlled in two stages, and the rough rolling is in the austenite complete recrystallization zone Rolling, the starting temperature is 1100°C, the finishing temperature of rough rolling is 1050°C, the finish rolling is rolled in the austenite incomplete recrystallization zone, the starting temperature is 900°C, and the finish rolling temperatur...

Embodiment 2

[0025] This embodiment provides a method for manufacturing a 3.5Ni steel plate for low-temperature containers. A steel plate with a thickness specification of 20 mm is produced by rolling a 150 mm thick billet with a steel coil mill. Including the following steps:

[0026] The composition of medium and thick plates is as follows: C: 0.066%, Si: 0.24%, Mn: 0.56%, S: 0.003%, P: 0.005%, Ni: 3.72%, Alt: 0.023%, and the balance is Fe and impurities; steelmaking according to the composition and continuous casting into a 150mm thick slab, the continuous casting slab is heated to 1150°C in a heating furnace, and kept for 2 hours; the rolling is controlled in two stages, and the rough rolling is completely recrystallized in the austenite Zone rolling, start rolling temperature 1050°C, rough rolling finish temperature 1020°C, finish rolling in the austenite incomplete recrystallization zone, start rolling temperature 890°C, finish rolling finish temperature 850°C; a total of eight passe...

Embodiment 3

[0028] This embodiment provides a method for manufacturing a 3.5Ni steel plate for low-temperature containers. A steel plate with a thickness specification of 20 mm is produced by rolling a 150 mm thick billet with a steel coil mill. Including the following steps:

[0029] The composition of medium and thick plates is as follows: C: 0.039%, Si: 0.14%, Mn: 0.83%, S: 0.0009%, P: 0.004%, Ni: 3.37%, Alt: 0.043%, and the balance is Fe and impurities; steelmaking according to the composition and continuous casting into a 150mm thick slab, the continuous casting slab is heated to 1170°C in a heating furnace, and kept for 2 hours; the rolling is controlled in two stages, and the rough rolling is completely recrystallized in the austenite Zone rolling, start rolling temperature is 1060°C, rough rolling finish temperature is 1050°C, finish rolling is rolled in austenite incomplete recrystallization zone, start rolling temperature is 830°C, finish rolling finish temperature is 810°C; a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com