Color change-preventing and wear-resistant protective agent of automotive interior metal zipper

A technology for metal zippers and automotive interiors, applied in anti-corrosion coatings, fire-resistant coatings, coatings, etc., can solve problems such as poor adhesion fastness, easy-to-contaminate fabrics, large pores, etc., to avoid discoloration of zippers, additives are environmentally friendly and non-toxic , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

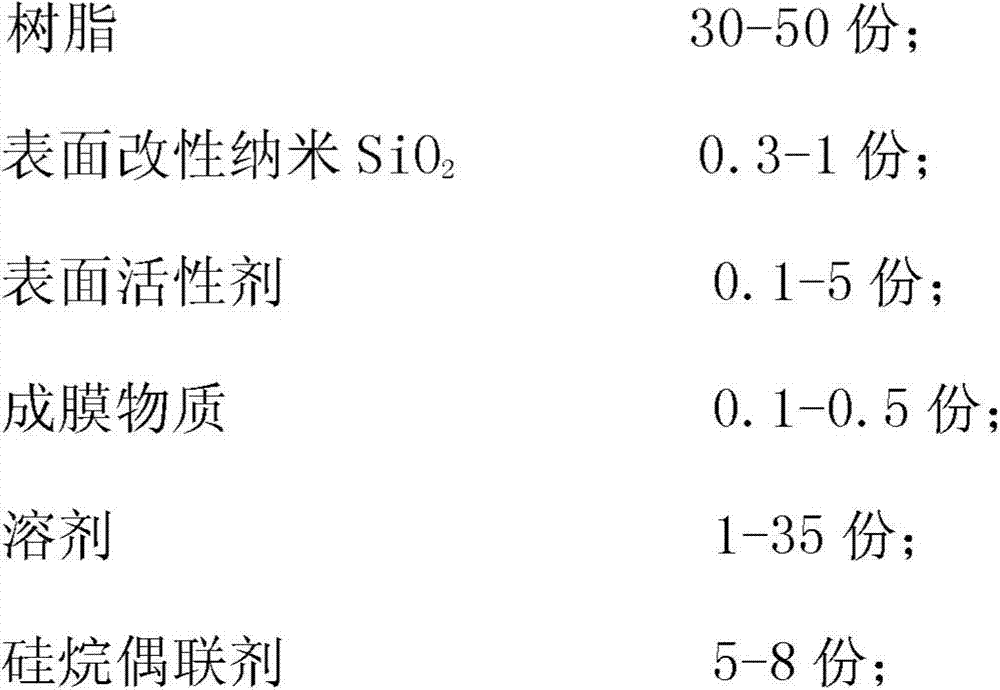

[0021] An anti-discoloration and wear-resistant protective agent for metal zippers in automobile interiors, the anti-discoloration and wear-resistant protective agent is composed of the following components in parts by weight:

[0022]

[0023] The resin is selected from one or two of acrylic emulsion, acrylic resin, bisphenol A epoxy resin, amino resin, polyurethane resin, polypolyol, phenolic resin, and urea-formaldehyde resin.

[0024] The surface modified nano-SiO 2 Nano-SiO modified by surface modifier and silane coupling agent 2 .

[0025] The surfactant is selected from one or both of alkylphenol polyoxyethylene ethers, nonylphenol polyoxyethylene ethers, fatty alcohol polyoxyethylene ethers, and fatty alcohol ethers-25.

[0026] The film-forming substance is selected from propoxylated glycerin triacrylate, o-phenylphenoxyethyl acrylate, modified polydimethylsiloxane polymer, dipropylene glycol butyl ether, tripropylene glycol butyl ether, ethyl One or two kinds o...

specific Embodiment 2

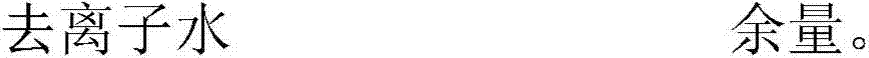

[0031] An anti-discoloration and wear-resistant protective agent for metal zippers in automobile interiors, the anti-discoloration and wear-resistant protective agent is composed of the following components in parts by weight:

[0032]

[0033] The resin is selected from one or two of acrylic emulsion, acrylic resin, bisphenol A epoxy resin, amino resin, polyurethane resin, polypolyol, phenolic resin, and urea-formaldehyde resin.

[0034] The surface modified nano-SiO 2 Nano-SiO modified by surface modifier and silane coupling agent 2 .

[0035] The surfactant is selected from one or both of alkylphenol polyoxyethylene ethers, nonylphenol polyoxyethylene ethers, fatty alcohol polyoxyethylene ethers, and fatty alcohol ethers-25.

[0036] The film-forming substance is selected from propoxylated glycerin triacrylate, o-phenylphenoxyethyl acrylate, modified polydimethylsiloxane polymer, dipropylene glycol butyl ether, tripropylene glycol butyl ether, ethyl One or two kinds o...

specific Embodiment 3

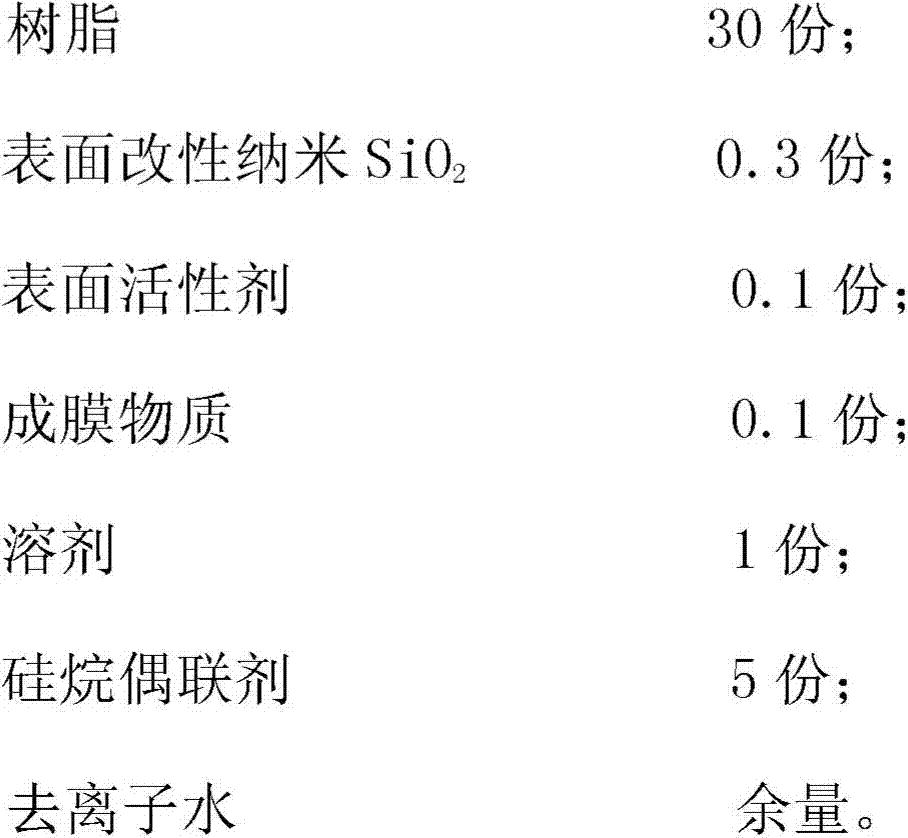

[0041] An anti-discoloration and wear-resistant protective agent for metal zippers in automobile interiors, the anti-discoloration and wear-resistant protective agent is composed of the following components in parts by weight:

[0042]

[0043] The resin is selected from one or two of acrylic emulsion, acrylic resin, bisphenol A epoxy resin, amino resin, polyurethane resin, polypolyol, phenolic resin, and urea-formaldehyde resin.

[0044] The surface modified nano-SiO 2 Nano-SiO modified by surface modifier and silane coupling agent 2 .

[0045] The surfactant is selected from one or both of alkylphenol polyoxyethylene ethers, nonylphenol polyoxyethylene ethers, fatty alcohol polyoxyethylene ethers, and fatty alcohol ethers-25.

[0046] The film-forming substance is selected from propoxylated glycerin triacrylate, o-phenylphenoxyethyl acrylate, modified polydimethylsiloxane polymer, dipropylene glycol butyl ether, tripropylene glycol butyl ether, ethyl One or two kinds of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com