Lithium-sulfur battery containing barrier layer

A lithium-sulfur battery and barrier layer technology, applied in the field of electrochemical batteries, can solve the problems such as the barrier layer is not easy to peel off, waste, etc., and achieve the effects of improving electrochemical performance, easy operation, and improving electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

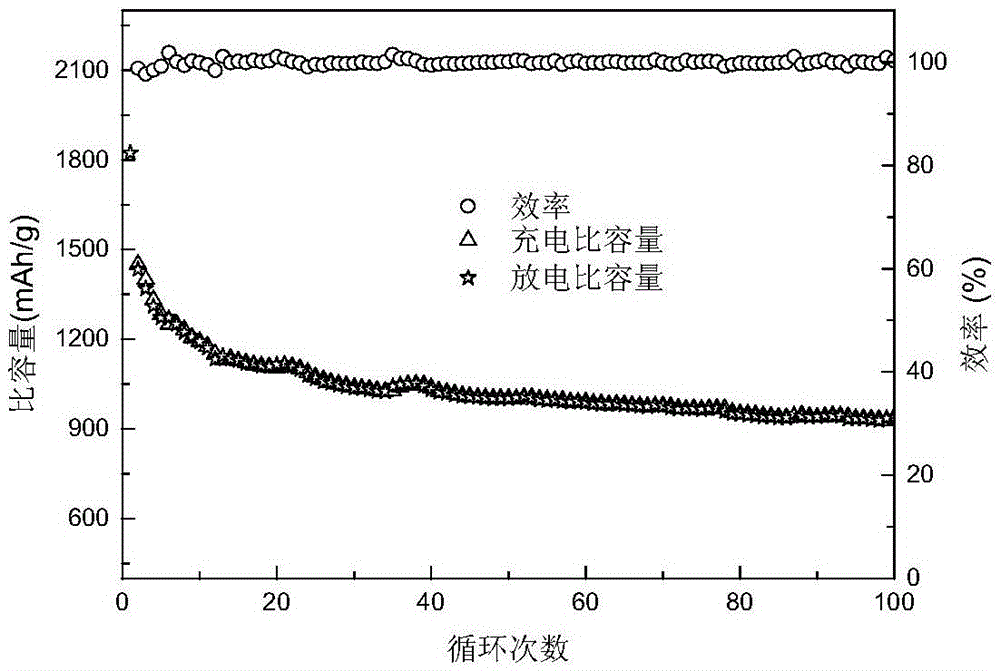

Examples

Embodiment 1

[0020] Pretreatment of aluminum foil current collector:

[0021] Cut the aluminum foil to a certain size and spread it on a clean glass plate, wash it repeatedly with ethanol and dry it at room temperature before use.

[0022] Preparation of positive electrode sheet:

[0023] The positive electrode active material sulfur, the conductive agent, and the N-methylpyrrolidone (NMP) solution of polyvinylidene fluoride (PVDF) were used as a binder, and mixed at a mass ratio of 7:2:1. Stir on a magnetic stirrer for 8 hours to obtain a viscous slurry; apply the viscous slurry evenly on the current collector, and then dry it in a vacuum oven at 50°C for 20 hours to obtain a positive pole piece.

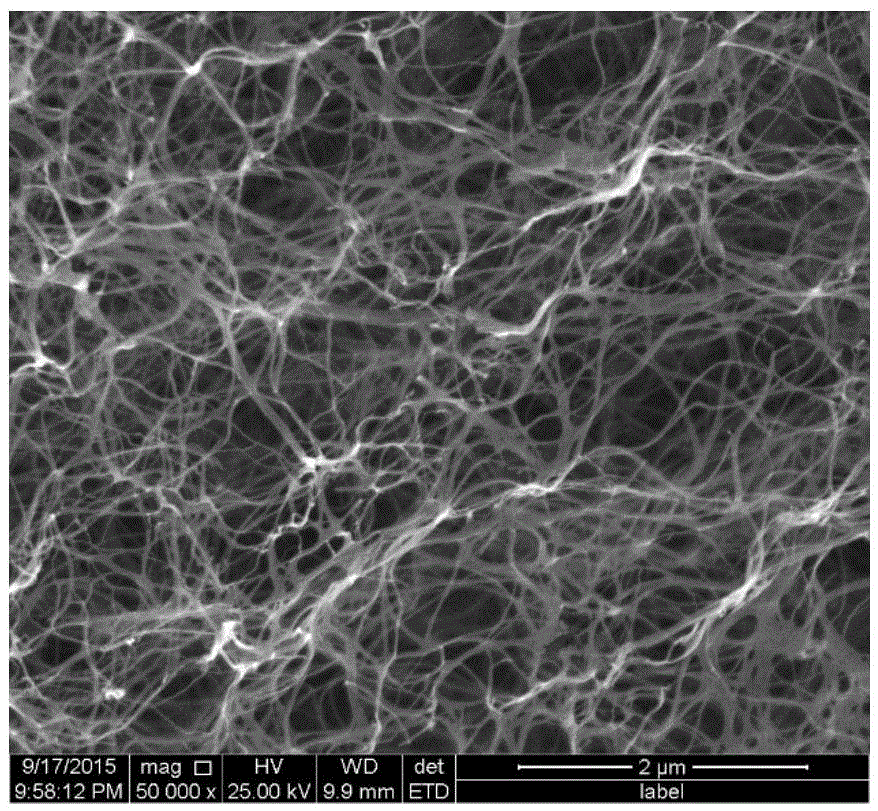

[0024] The preparation method of bacterial cellulose derivatized carbon fiber barrier layer is:

[0025] The bacterial cellulose hydrogel was cut into small pieces with a blade, washed several times with deionized water, and then soaked in deionized water for 1 day. The bacterial cellulose w...

Embodiment 2

[0032] Pretreatment of aluminum foil current collector:

[0033] Cut the aluminum foil to a certain size and spread it on a clean glass plate, wash it repeatedly with ethanol and dry it at room temperature before use.

[0034] Preparation of positive electrode sheet:

[0035] The positive electrode active material sulfur, the conductive agent, and the N-methylpyrrolidone (NMP) solution of polyvinylidene fluoride (PVDF) were used as a binder, and mixed at a mass ratio of 7:2:1. Stir on a magnetic stirrer for 8 hours to obtain a viscous slurry; apply the viscous slurry evenly on the current collector, and then dry it in a vacuum oven at 50°C for 20 hours to obtain a positive pole piece.

[0036] The preparation method of activated carbon barrier layer is:

[0037]Disperse the activated carbon in the ethanol solution, place the PVDF membrane in the Millipore ultrafiltration cup, then pour the dispersed activated carbon suspension into the ultrafiltration cup, and adjust the gas...

Embodiment 3

[0043] Pretreatment of aluminum foil current collector:

[0044] Cut the aluminum foil to a certain size and spread it on a clean glass plate, wash it repeatedly with ethanol and dry it at room temperature before use.

[0045] Preparation of positive electrode sheet:

[0046] The positive electrode active material sulfur, the conductive agent, and the N-methylpyrrolidone (NMP) solution of polyvinylidene fluoride (PVDF) were used as a binder, and mixed at a mass ratio of 7:2:1. Stir on a magnetic stirrer for 8 hours to obtain a viscous slurry; apply the viscous slurry evenly on the current collector, and then dry it in a vacuum oven at 50°C for 20 hours to obtain a positive pole piece.

[0047] The preparation method of barrier layer is:

[0048] Disperse the graphite powder in the ethanol solution, place the PVDF membrane in the Millipore ultrafiltration cup, then pour the dispersed graphite powder suspension into the ultrafiltration cup, and adjust the gas pressure of the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com