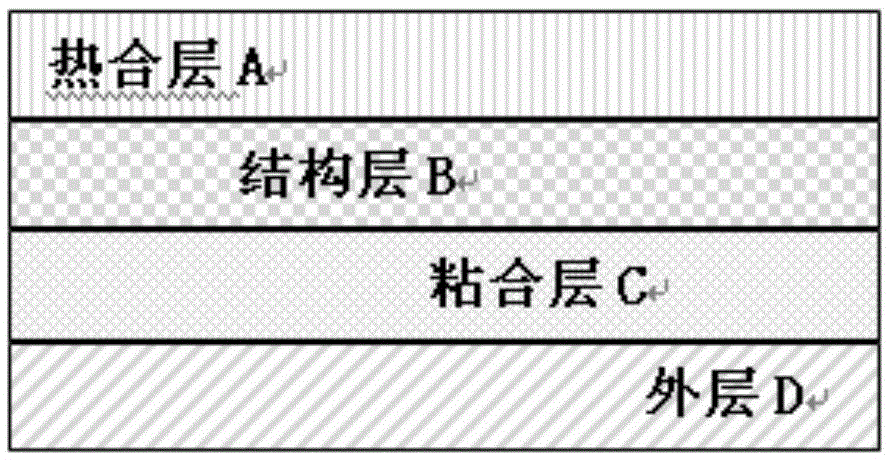

Disposable venous nutrition transfusion bag film and making method thereof

An infusion bag, a disposable technology, applied in the field of medical devices, can solve the problems of poor protection of treatment and nutritional infusion, increased manufacturing costs, and reduced efficacy of drugs, and achieve excellent drug compatibility, reduce the probability of deterioration, migration and precipitation The effect of less

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

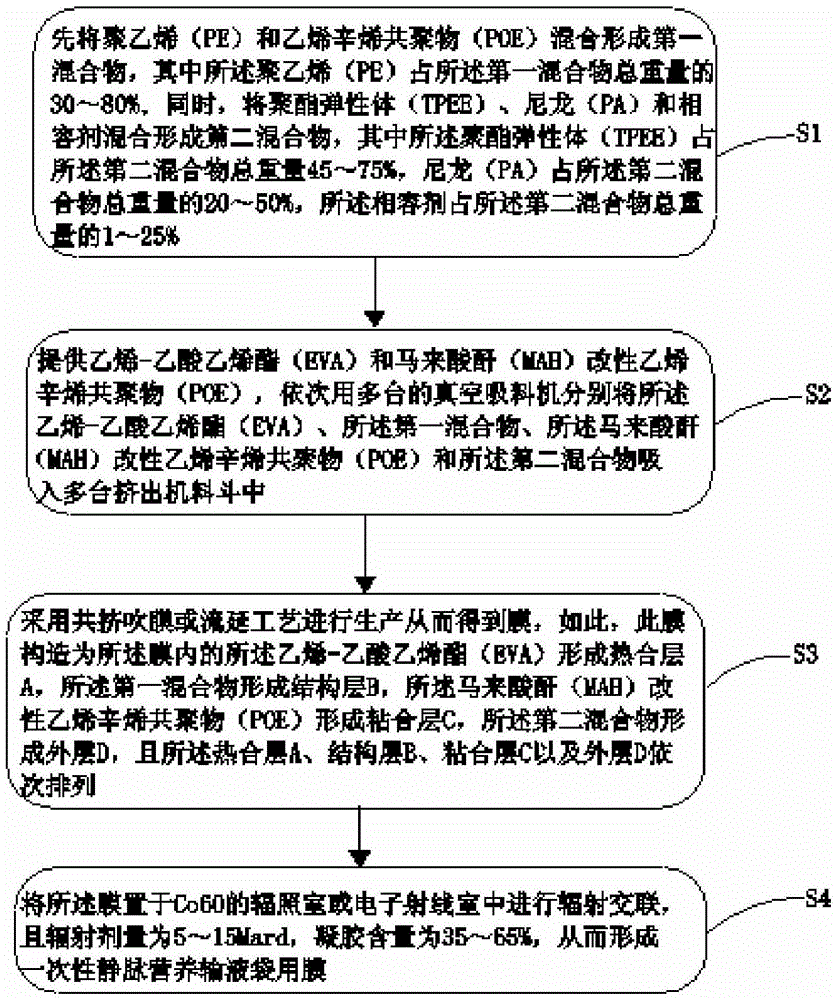

[0038] Such as figure 2 Shown, for the preparation method of a kind of disposable intravenous nutrition infusion bag film provided by the present invention, comprises the following steps:

[0039] S1: first mix polyethylene (PE) and ethylene octene copolymer (POE) to form a first mixture, wherein the polyethylene (PE) accounts for 30-80% of the total weight of the first mixture; Ester elastomer (TPEE), nylon (PA) and compatibilizer are mixed to form a second mixture, wherein said polyester elastomer (TPEE) accounts for 45% to 75% of the total weight of said second mixture, and nylon (PA) accounts for all The compatibilizer accounts for 20-50% of the total weight of the second mixture, and the compatibilizer accounts for 1-25% of the total weight of the second mixture.

[0040] Specifically, the melt flow index of the polyethylene (PE) under the conditions of 190°C and 2.16kg is 0.5-5g / 10min, the melting point is 80-120°C, and the density is 0.89-0.92g / cm 3 , the melt flow i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com