Synthetic method of high-purity ultrafine ZrC-SiC composite powders

一种复合粉体、合成方法的技术,应用在化学仪器和方法、碳化合物、无机化学等方向,能够解决热分解产物坚硬、准确配制困难、易发泡和流失等问题,达到来源方便、容易研磨粉碎细化、比例准确不变的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

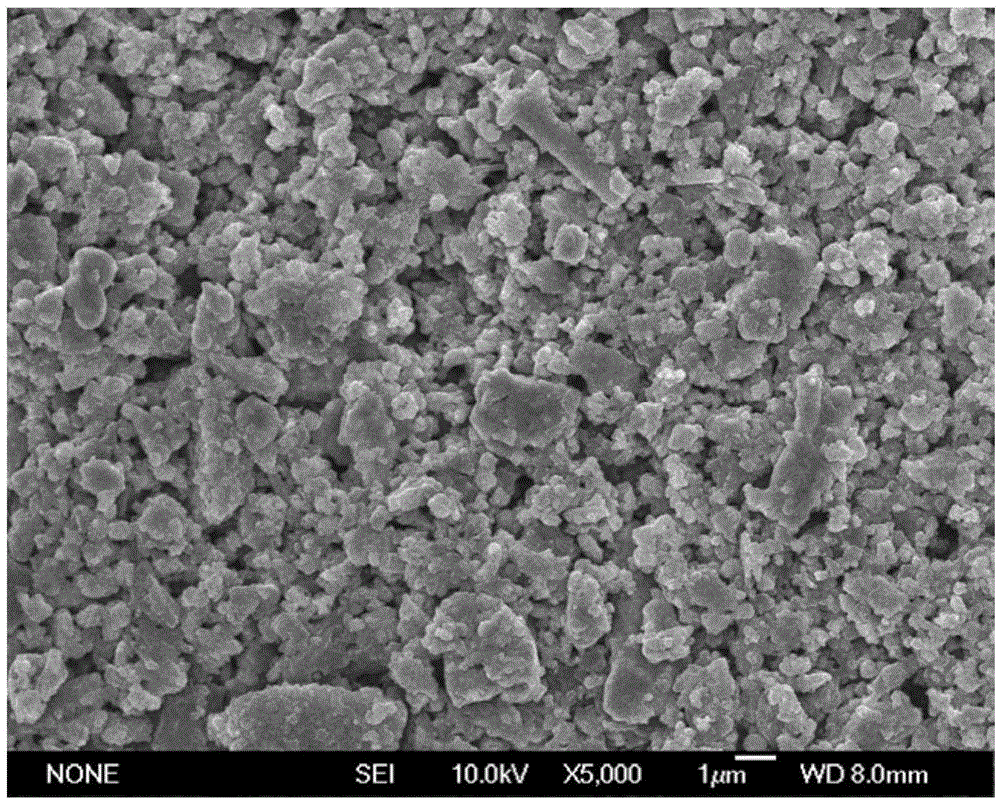

Image

Examples

Embodiment 1

[0049] Synthesis of 50mol% ZrC-50mol% SiC composite powder

[0050] Accurately weigh 200g of zirconium silicate micropowder and 249g of sucrose, i.e. (Zr+Si): C=1:4, add to 150ml of deionized water, and add 3ml of ammonium polyacrylate dispersant, mix and grind in a roller mill for 12h to obtain Water-based slurry with good suspension stability; add 30g of acrylamide monomer and 1.5g of methylene bisacrylamide cross-linking agent, continue to mix and grind for 1 hour, pour it into a beaker, add dropwise 10% ammonium persulfate aqueous solution to trigger Add 2ml of 50% concentration of tetramethylethylenediamine solution dropwise, then add 1.5ml of catalyst in aqueous solution of tetramethylethylenediamine, stir evenly, let it stand for about 3min, and then the in-situ gel solidifies; pound the wet gel into pieces and put it in a 100°C oven Dry in medium for 16 hours, then heat up to 220°C for pretreatment for 8 hours; put the pretreated jelly block into a graphite crucible, k...

Embodiment 2

[0052] Synthesis of 75mol% ZrC-25mol% SiC Composite Powder

[0053] Accurately weigh 1833g zirconium silicate micropowder, 2464g zirconia micropowder, 3993g sucrose, (Zr:Si:C=0.75:0.25:3.5), add to 2000ml deionized water, and add 60ml ammonium polyacrylate dispersant, in the roller mill The water-based slurry with good suspension stability was obtained after medium mixing for 12 hours. Then add 200g of acrylamide monomer, 15g of N',N'-methylene bisacrylamide cross-linking agent, continue to mix and grind for 1 hour, pour it into an enamel tank, add 15% concentration of oxidation-reduction agent aqueous solution 15ml (ammonium persulfate : Ammonium sulfite = 1.5: 1), stir evenly and let stand for about 5 minutes, the water-based slurry gel solidifies in situ; the wet gel is cut into thin slices ≤ 3mm thick with a zirconia ceramic knife, and heated at 120°C Dry in an oven for 12 hours, then raise the temperature to 180°C for pretreatment for 24 hours; put it into a graphite cru...

Embodiment 3

[0056] Synthesis of 90mol% SiC-10mol% ZrC Composite Powder

[0057] Accurately weigh 183.3g zirconium silicate micropowder, 1200g glucose, add 1600g silica sol (concentration is 30wt%, i.e. SiO 2 The content is 480g, at this time Si:Zr:C=0.9:0.1:4), mixed in a roller mill for 8h to obtain a water-based slurry with good suspension stability. Then add 150g of acrylamide monomer, 6g of N',N'-methylenebisacrylamide cross-linking agent, continue to mix and grind for 2 hours, then discharge the material into the enamel pot, add azobisisobutylamidine hydrochloride with a concentration of 5% 10ml of saline solution, stir evenly, and keep warm in a 70°C water bath for about 5 minutes, and the water-based slurry will gel and solidify in situ. Break the wet gel into pieces, dry it in an oven at 100°C for 16 hours, then raise the temperature to 200°C for 10 hours, put it into a graphite crucible, and heat it to 1450°C for 2 hours under the protection of argon in a carbon tube heating fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com