Production method for protective feed acidifier

A technology of feed acidifier and production method, which is applied in the field of feed processing, can solve the problems of large one-time investment, high one-time investment of plant and equipment, and low melting point active ingredients, so as to ensure health and integrity, good promotion value, and products The effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0094] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

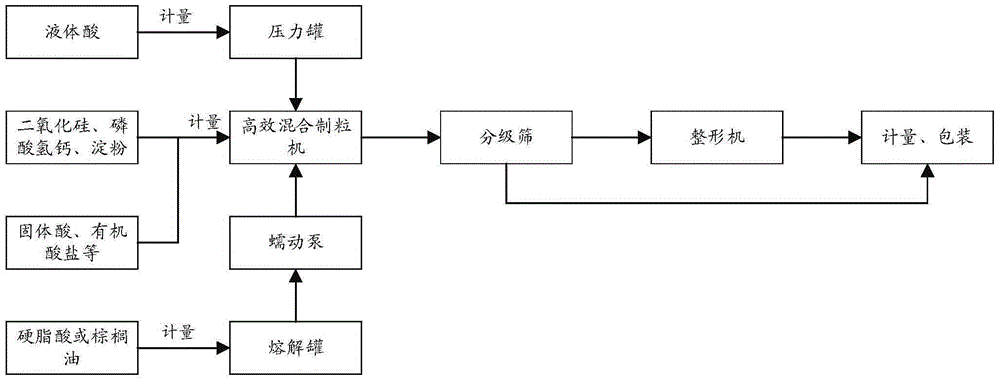

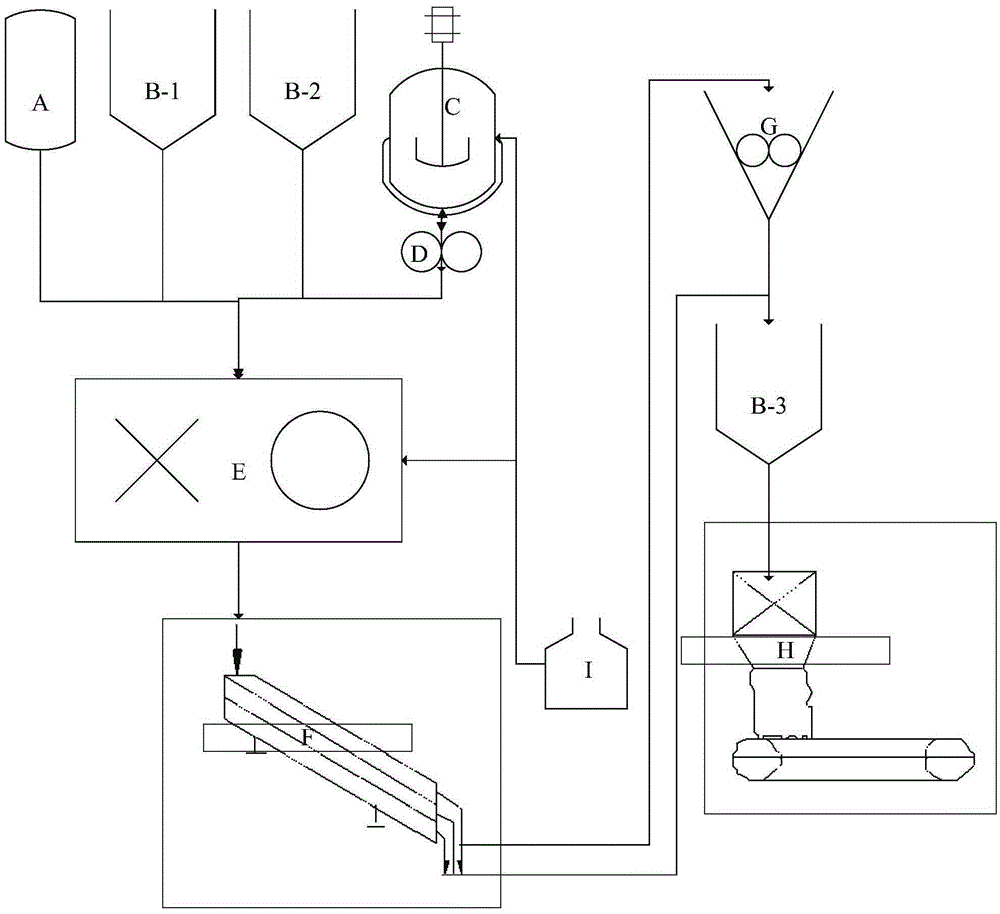

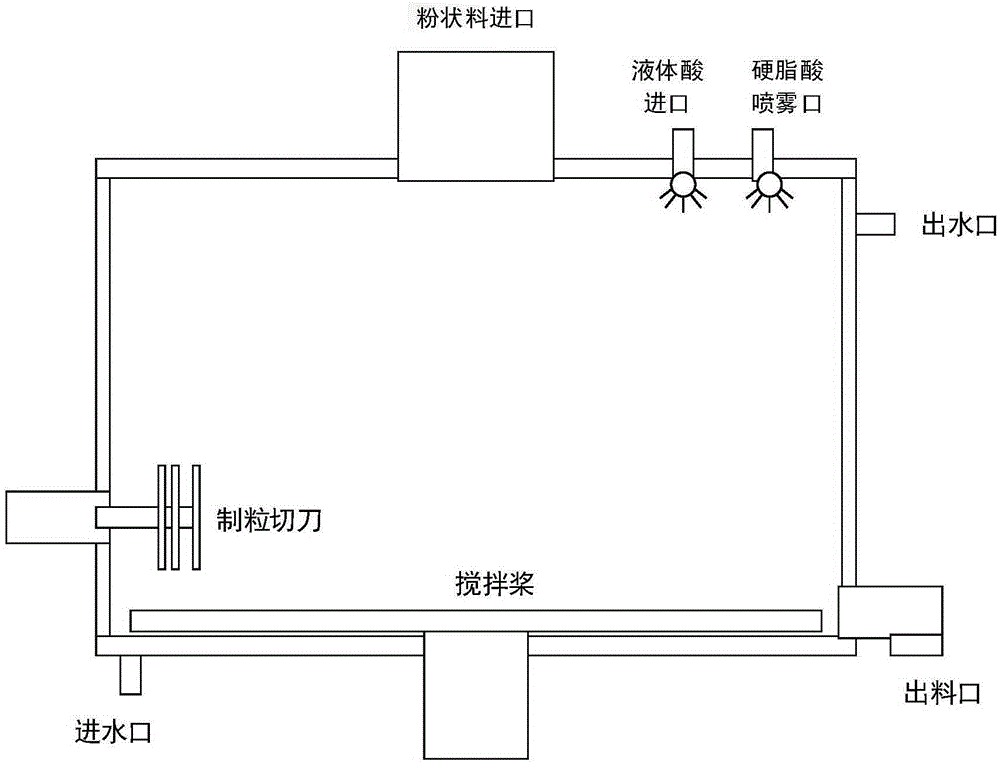

[0095] Such as Figure 1~3 The production method of shown protective type feed acidifier, specific embodiment is as follows:

[0096] 1) Material preparation:

[0097] Add liquid acid (phosphoric acid, lactic acid, etc.) into the liquid pressure tank (A) according to the formula, and set aside;

[0098] Add silicon dioxide, calcium hydrogen phosphate, starch, etc. into the material bin (B-1) according to the formula requirements, and set aside;

[0099] Add solid acids (citric acid, fumaric acid, malic acid) and organic acid salts (calcium formate, calcium propionate, calcium lactate, etc.) into the material bin (B-2) according to the formula requirements, and set aside;

[0100] Stearic acid or palm oil is added into the melting tank (C) according to the formula requirements, and stirred and melted at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com