Potassium iodate preparation method

A technology of potassium iodate and potassium iodide, applied in the direction of iodine oxygen compounds, can solve the problems of three wastes, high toxicity of chlorine gas, high energy consumption, etc., and achieve the effect of uniform product particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

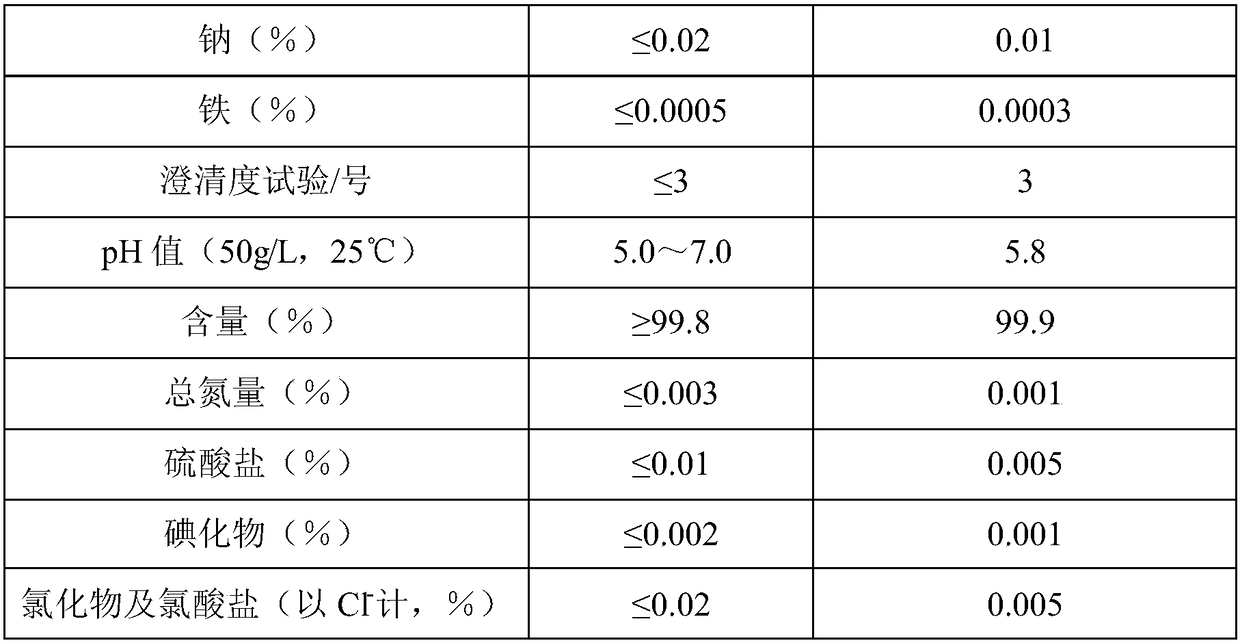

Image

Examples

Embodiment 1

[0016] A preparation method of potassium iodate, comprising the following steps:

[0017] (1) get 498g potassium iodide and 12.8g hydroiodic acid and be dissolved in 1000g water under room temperature and make potassium iodide aqueous solution;

[0018] (2) take by weighing 1166g mass concentration and be 30% hydrogen peroxide, under room temperature, potassium iodide aqueous solution and hydrogen peroxide are added in the first reaction module and the second reaction module of microchannel reactor respectively according to the mass ratio of 1.29:1 with feed pump Mix the reaction, control the reaction residence time to be 30S, and obtain the first reaction liquid;

[0019] (3) take by weighing 58.3g mass concentration and be 30% hydrogen peroxide, the first reaction solution that obtains and the hydrogen peroxide that weighs are passed in the 3rd reaction module of microchannel reactor simultaneously according to the mass ratio of 46:1, control reaction stays The time is 15S ...

Embodiment 2

[0024] A preparation method of potassium iodate, comprising the following steps:

[0025] (1) get 678g potassium iodide and 17.8g hydroiodic acid and be dissolved in 1000g water under room temperature and make potassium iodide aqueous solution;

[0026] (2) take by weighing 1615g mass concentration and be 28% hydrogen peroxide, under room temperature, potassium iodide aqueous solution and hydrogen peroxide are added in the first reaction module and the second reaction module of microchannel reactor respectively according to the mass ratio of 1.05:1 with feed pump Mix the reaction, control the reaction residence time to be 30S, and obtain the first reaction solution;

[0027] (3) take by weighing 69g mass concentration and be 28% hydrogen peroxide, the first reaction liquid that obtains and the hydrogen peroxide that weighs are passed in the third reaction module of microchannel reactor simultaneously according to the mass ratio of 48:1, control reaction residence time is 15S ...

Embodiment 3

[0030] A preparation method of potassium iodate, comprising the following steps:

[0031] (1) get 434.8g potassium iodide and 10.9g hydroiodic acid and be dissolved in 1000g water under room temperature and make potassium iodide aqueous solution;

[0032] (2) take by weighing 1032.8g mass concentration and be 29% hydrogen peroxide, under room temperature, potassium iodide aqueous solution and hydrogen peroxide are 1.4:1 according to mass ratio and add respectively the first reaction module and the second reaction module of microchannel reactor with feed pump Medium mixed reaction, control reaction residence time is 30S, obtains the first reaction solution;

[0033] (3) take by weighing 63.6g mass concentration and be the hydrogen peroxide of 29%, the first reaction solution obtained and the hydrogen peroxide that weighs are passed in the third reaction module of microchannel reactor simultaneously according to the mass ratio of 39:1, control reaction stay The time is 15S to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com