3D blowing membrane

An air film, 3D technology, applied in the direction of adhesive additives, layered products, synthetic resin layered products, etc., can solve the problems of easy brittleness, poor comprehensive performance, poor waterproof performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

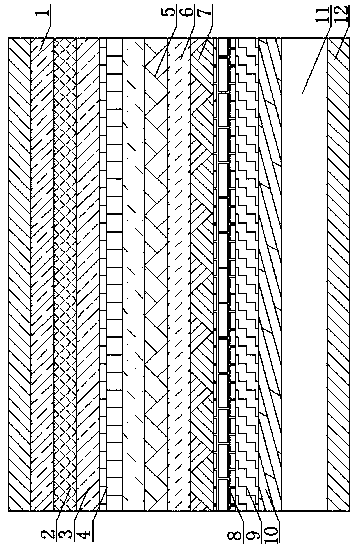

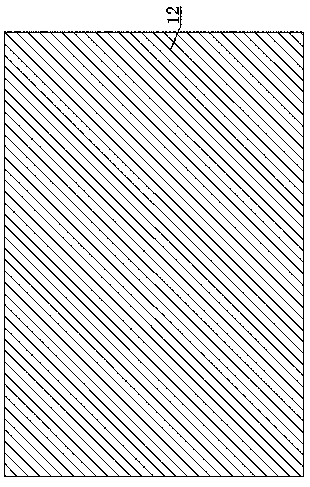

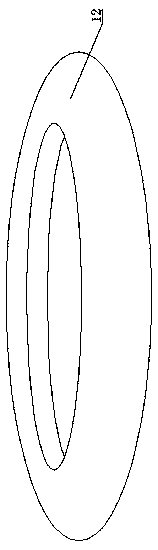

[0012] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0013] refer to Figure 1-3 , a 3D blown film, including an annular film body, the annular mold body includes a TPU film layer 11, using the TPU film layer 11 to replace the traditional PVC film layer, which is conducive to improving the performance of the blown film, TPU is a mature Environmentally friendly and non-toxic materials, it has the characteristics of high strength, good toughness, wear resistance, aging resistance, weather resistance, heat resistance and cold resistance, which are unmatched by other plastics and natural materials, and has high pressure bearing capacity, which can effectively improve the final The quality of the blown film; the upper end o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com