Aeolotropic super-hydrophobic surface of aluminum material and preparation method of aeolotropic super-hydrophobic surface

A super-hydrophobic surface and anisotropic technology, applied in the coating process of metal materials, etc., can solve the problems of strong adhesion, difficult rolling, and small adhesion, so as to reduce surface tension, promote oxidation process, and improve corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

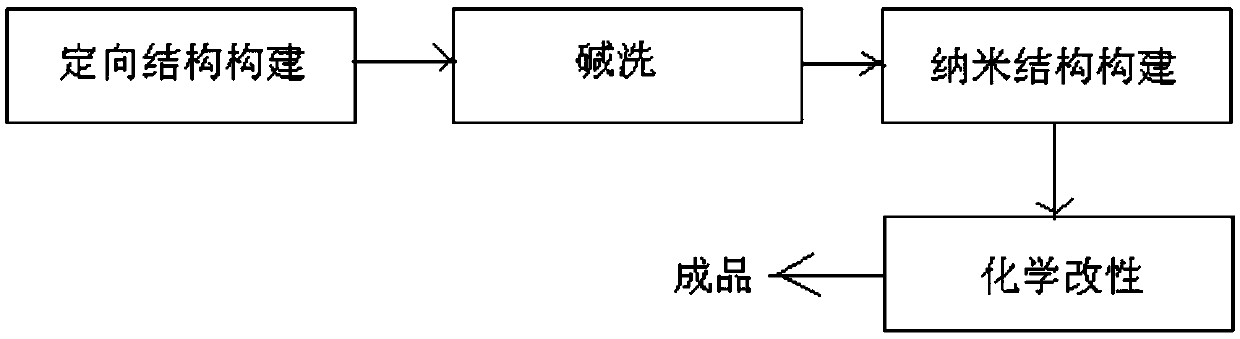

[0035] A preparation technology for the anisotropic superhydrophobic surface of an aluminum material, comprising the following processing steps:

[0036] (1) Construction of directional structure: fix the aluminum or aluminum alloy material, first use the tool for directional rough grinding for 10-20 times, and then perform directional fine grinding for 10-20 times in the same direction, and the rough grinding tool can be 150-240 An industrial scouring pad with a particle size of 80-400 mesh, or a wire brush with a wire diameter of 0.3-0.5mm, and the fine grinding tool can be an industrial scouring pad with a particle size of 320-1000, or a mesh of 600-1200 Metallographic sandpaper, or a wire brush with a wire diameter of 0.1-0.2mm, different types of coarse grinding and fine grinding tools can be used interchangeably;

[0037] (2) Alkaline cleaning: Ultrasonic clean the polished sample in acetone, alcohol and deionized water for 5 minutes, dry it and immerse it in a NaOH solu...

Embodiment 1

[0041] (1) Directional structure construction: Fix the aluminum or aluminum alloy material, first use 80-mesh coarse sandpaper for 15 times of directional rough grinding, and then use 600-mesh fine sandpaper for 15 times of directional fine grinding in the same direction;

[0042] (2) Alkaline cleaning: ultrasonically clean the polished sample in acetone, alcohol and deionized water for 5 minutes, blow dry, immerse in NaOH solution with a concentration of 0.2mol / L for 60 seconds, wash with deionized water, dry and set aside ;

[0043] (3) Nanostructure construction: put the polished and alkali-washed sample into deionized solution with a mass fraction of 0.3% triethanolamine boiled, and add 1% polyoxyethylamine surfactant, after heating for 30 minutes, stop heating, After the solution is cooled, take out the sample, wash it with deionized water, and blow dry;

[0044] (4) Chemical modification: Soak the sample in 1.0% fluorosilane ethanol solution, keep it warm in a 60°C wate...

Embodiment 2

[0046] (1) Construction of directional structure: Fix the aluminum or aluminum alloy material, first use 240-mesh coarse sandpaper for 20 times of directional rough grinding, and then use 1000-mesh fine sandpaper for 10 times of directional fine grinding in the same direction;

[0047] (2) Alkaline cleaning: ultrasonically clean the polished sample in acetone, alcohol and deionized water for 5 minutes, blow dry, immerse in NaOH solution with a concentration of 0.2mol / L for 60 seconds, wash with deionized water, dry and set aside ;

[0048] (3) Construction of nanostructure: put the polished and alkali-washed sample into deionized solution with a mass fraction of 1.2% triethanolamine, and add 0.5% anionic surfactant sodium lauryl sulfate. After heating for 60 minutes, stop Heating, after the solution is cooled, take out the sample, wash it with deionized water, and blow dry;

[0049] ⑷Chemical modification: Soak the sample in 1.0% fluorosilane ethanol solution, keep it warm in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com