Oil-displacing composition, preparing method of oil-displacing composition and intensified oil production method

A composition and oil displacement technology, which are applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve the problems of poor oil displacement efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] (1) The anionic surfactant structural formula of preparation is as follows, wherein R 1 The carbon chain distribution is: C 12 72.3wt%, C 14 27.7wt%, m 1 +m 2 = 3, n 1 +n 2 =20, m 3 +m 4 =8.

[0066]

[0067] Add 192.6 grams (1 mole) of mixed twelve / fourteen (C 12~14 ) amine, 9.5 grams of potassium hydroxide, when heated to 80-90°C, turn on the vacuum system, dehydrate under high vacuum for 1 hour, then replace with nitrogen for 3-4 times, adjust the reaction temperature of the system to 110°C and slowly introduce 132.9 grams (3.02 moles) of ethylene oxide, the control pressure is ≤0.50MPa, after the reaction of ethylene oxide is completed, slowly feed 1171.6 grams (20.2 moles) of propylene oxide at 150°C, the control pressure is ≤0.60MPa, wait After the propylene oxide reaction, the temperature was adjusted to 130° C. and 354.2 g (8.05 moles) of ethylene oxide was slowly introduced. After the reaction, lower the temperature to 90°C, remove low boilers in a...

Embodiment 2

[0075] (1) with 【Example 1】, the difference is that mixing twelve / fourteen (C 12~14 ) amine polyoxyethylene (3) polyoxypropylene (20) polyoxyethylene (8) ether and sodium chloroacetate do not need to be treated with acid after reacting, that is, after reflux reaction for 3 hours, change the distillation device to remove the solvent toluene / distillate Toluene (v / v=1), add water to the residue and stir evenly to obtain nonionic and anionic mixed surfactant S-2 containing sodium chloride and sodium hydroxide.

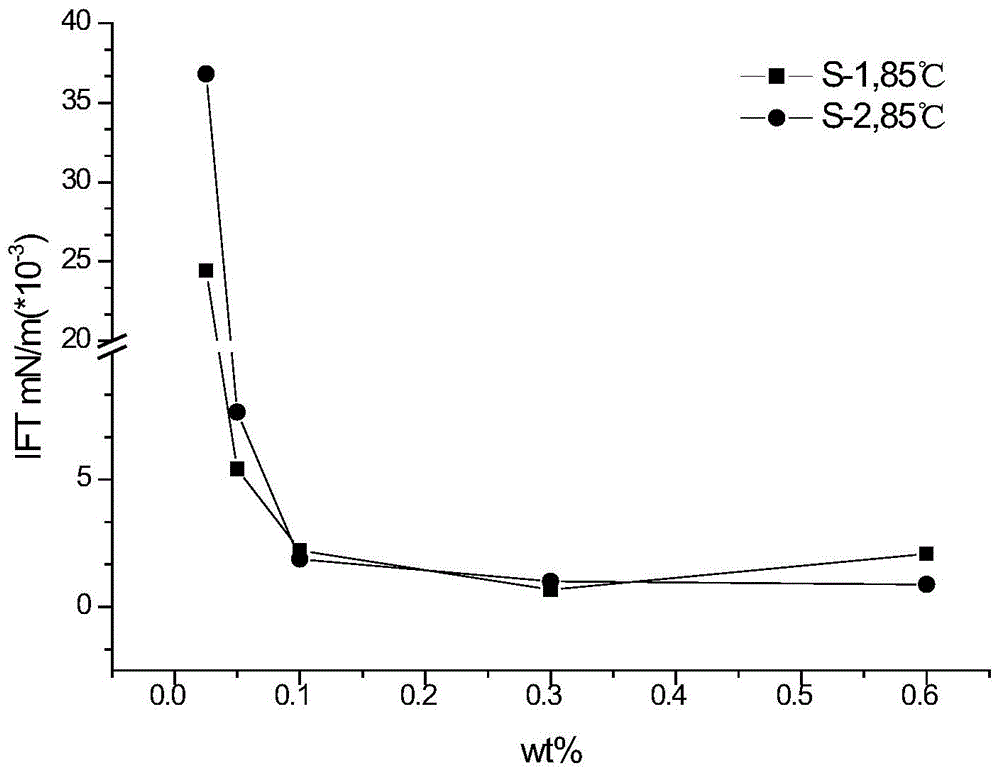

[0076] (2) Prepare the S-2 and modified polyacrylamide (P1, copolymerized AM / AMPS molar ratio = 2 / 1, viscosity-average molecular weight 15 million) aqueous solution prepared in step (1) respectively with Shengli Oilfield simulated formation water 1, and stir 4 hours, all the other are the same as [Example 1] (2), and the results are shown in Table 2. The oil-water interfacial tension of different concentrations of S-2 aqueous solutions, see figure 1 shown.

[0077] (3) ...

Embodiment 3

[0081] (1) The anionic surfactant structural formula prepared is as follows, wherein, m 1 +m 2 =8,n 1 +n 2 =16,m 3 +m 4 =15.

[0082]

[0083] Add 261 grams (1 mole) of dodecylaniline, 5.2 grams of sodium hydroxide and 13.1 grams of Anhydrous Potassium Carbonate in the 5L pressure reactor that stirrer is equipped with, carry out water removal and nitrogen replacement with [embodiment 1], Adjust the reaction temperature of the system to 110°C and slowly feed 354.2 grams (8.05 moles) of ethylene oxide, and control the pressure to ≤0.50 MPa. After the reaction of ethylene oxide is completed, slowly feed 933.8 grams (16.1 moles) ) Propylene oxide, control pressure≤0.60MPa, after the completion of the reaction of propylene oxide, adjust the temperature to 140°C and slowly feed 664.4 grams (15.1 moles) of ethylene oxide. After the reaction, the same post-treatment as in [Example 1] was carried out to obtain dodecylaniline polyoxyethylene (8) polyoxypropylene (16) polyoxyeth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com