Carbonyl-containing material-coated barium titanate/polymer composite film and preparation method thereof and application

A technology of coating barium titanate and carbonyl materials, which is applied in the field of thin film dielectric materials, can solve environmental pollution and other problems, and achieve the effects of ensuring flexibility, high electrical breakdown strength, and high energy storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

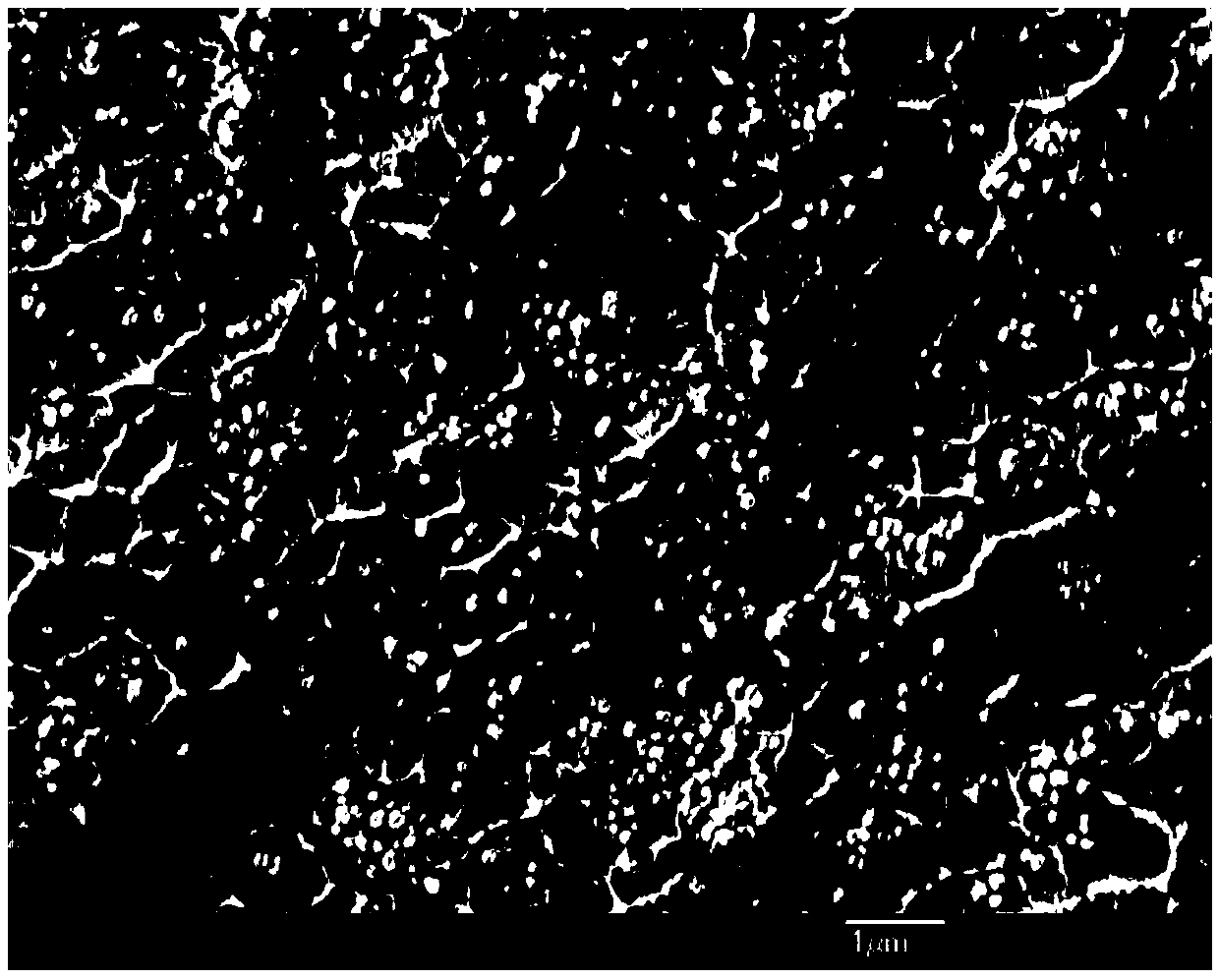

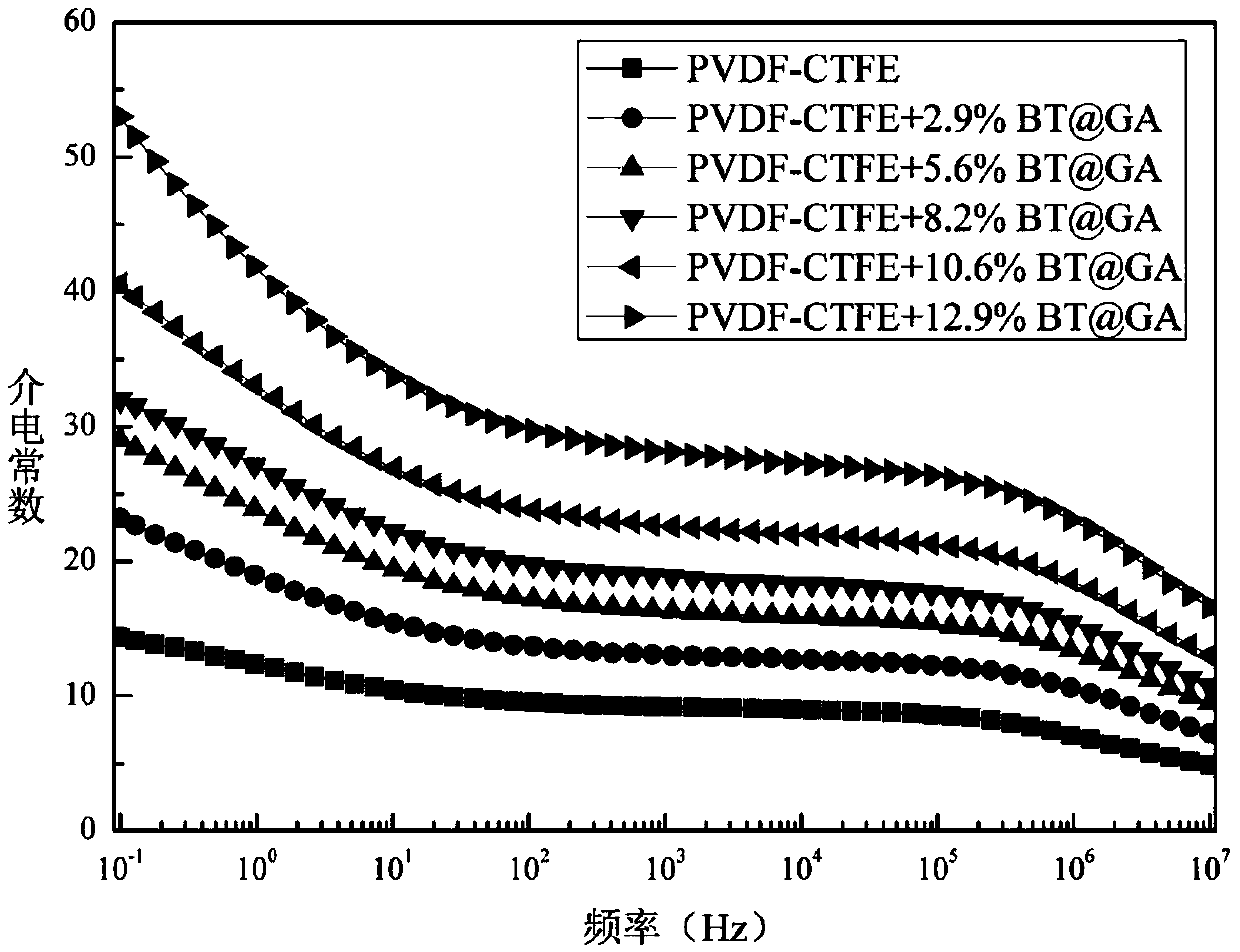

[0051] Commercial BaTiO with a particle size of 100 nm 3 Add water and water into a three-necked flask at a mass ratio of 3:20, ultrasonically and stir for 1 hour. Press BaTiO under ultrasound and stirring 3 5% of the mass was added with 3,4,5-trihydroxybenzoic acid, ultrasonicated and stirred for 1 h. Subsequently, the temperature was raised to 75°C under stirring, kept for 24 hours, then cooled to room temperature and settled for 24 hours. Centrifuge the upper layer mixture, and add the precipitated nanoparticles into water to wash. The mass ratio of nanoparticles to water is 1:20. After ultrasonication and stirring for 1 hour, centrifuge and dry to obtain the particles coated with 3,4,5-trihydroxyl Barium titanate nanoparticles of benzoic acid (abbreviated as BT@GA).

[0052] Dissolve polyvinylidene fluoride-co-chlorotrifluoroethylene (molecular weight: 300,000) in N,N-dimethylformamide to obtain a 10 wt% solution, and let it stand for 24 hours for defoaming.

[0053] T...

Embodiment 2

[0076] Commercially available barium titanate with a particle size of 100nm was coated with 4,4'-dihydroxybenzophenone containing a high-moment carbonyl functional group in the same manner as in Example 1, and polyvinylidene fluoride- 0%, 2.9%, 5.6%, 8.2%, 10.6%, 12.9% of the volume of co-chlorotrifluoroethylene added polyvinylidene fluoride-co-chlorotrifluoroethylene (molecular weight: 300,000) In formamide solution, ultrasonic, stirring and dispersing, casting into film, hot pressing treatment. The dielectric constant and electrical breakdown strength were tested in the same way, and the results are shown in Table 5 respectively.

[0077] According to the energy storage density U e =1 / 2·ε 0 ·ε r ·E b 2 Calculate the theoretical energy storage density of the above film capacitors, see Table 5.

[0078] Under the electric field strength of 0.5MV / cm, the D-E curve of the above-mentioned composite film was tested by the Sawyer-Tower circuit, and the charge density and disc...

Embodiment 3

[0085] Commercially available barium titanate with a particle size of 100 nm is coated with glycine containing a high-moment carbonyl functional group in the same manner as in Example 1, and the volume of polyvinylidene fluoride-co-chlorotrifluoroethylene is 0%. , 2.9%, 5.6%, 8.2%, 10.6%, 12.9% were added to the N,N-dimethylformamide solution of polyvinylidene fluoride-co-chlorotrifluoroethylene (molecular weight: 300,000), ultrasonically and stirred to disperse, Film casting, hot pressing treatment. The dielectric constant and electrical breakdown strength were tested in the same way, and the results are shown in Table 7 respectively.

[0086] According to the energy storage density U e =1 / 2·ε 0 ·ε r ·E b 2 Calculate the theoretical energy storage density of the above film capacitors, see Table 7.

[0087] Under the electric field strength of 0.5MV / cm, the D-E curve of the above-mentioned composite film was tested by the Sawyer-Tower circuit, and the charge density and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com