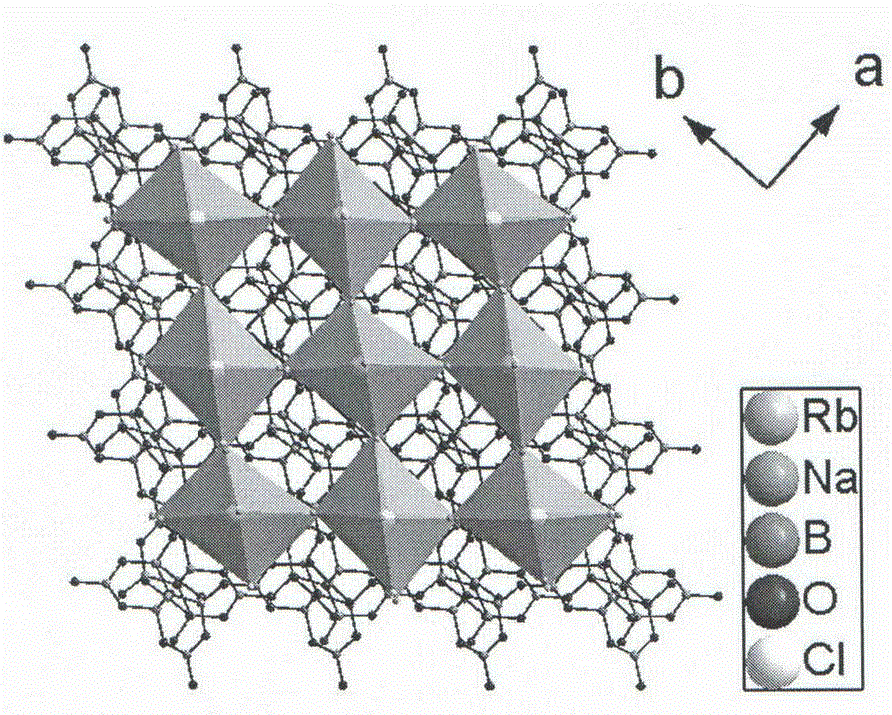

Compound rubidium sodium chloroborate, and rubidium sodium chloroborate optical crystal and preparation method and application thereof

A technology of sodium rubidium chloroborate and optical crystals, which is applied in chemical instruments and methods, boron halide compounds, optics, etc., and can solve problems such as high price, long growth cycle, and deliquescent crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] According to the reaction formula: Rb 2 CO 3 +Na 2 CO 3 +2NaCl+12H 3 BO 3 →2RbNa 2 B 6 o 10 Cl+18H 2 O↑+2CO 2 ↑Synthesis of RbNa 2 B 6 o 10 Cl compounds:

[0061] Rb 2 CO 3 、Na 2 CO 3 , NaCl, H 3 BO 3 Weigh the raw materials at a molar ratio of 1:1:2:12, put them into a mortar, mix and grind carefully, then put them into a Φ100mm×100mm open corundum crucible, put them into a muffle furnace, and slowly raise the temperature to 350°C, Keep the temperature for 24 hours, cool to room temperature, take it out and put it into the muffle furnace after the second grinding, then raise the temperature to 500°C, keep the temperature for 24 hours, cool to room temperature, take it out and put it into the muffle furnace after the third grinding, Then raise the temperature to 650°C, keep the temperature for 72 hours, take out and grind the single-phase polycrystalline powder of rubidium sodium chloroborate compound, and then carry out X-ray analysis on the product,...

Embodiment 2

[0068] According to the reaction formula: Rb 2 O+Na 2 CO 3 +2NaCl+12H 3 BO 3 →2RbNa 2 B 6 o 10 Cl+18H 2 O↑+CO 2 ↑Synthesis of RbNa 2 B 6 o 10 Cl compounds:

[0069] Rb 2 O, Na 2 CO 3 , NaCl, H 3 BO 3 Weigh the raw materials directly according to the molar ratio of 1:1:2:12, and combine the weighed raw materials with the flux H 3 BO 3 -Na 2 O is mixed at a molar ratio of 1:4, where H 3 BO 3 with Na 2 The molar ratio of O is 3:1, put it into an open platinum crucible of Φ80mm×80mm, heat up to a temperature of 780°C, and keep the temperature for 20 hours to obtain a mixed melt;

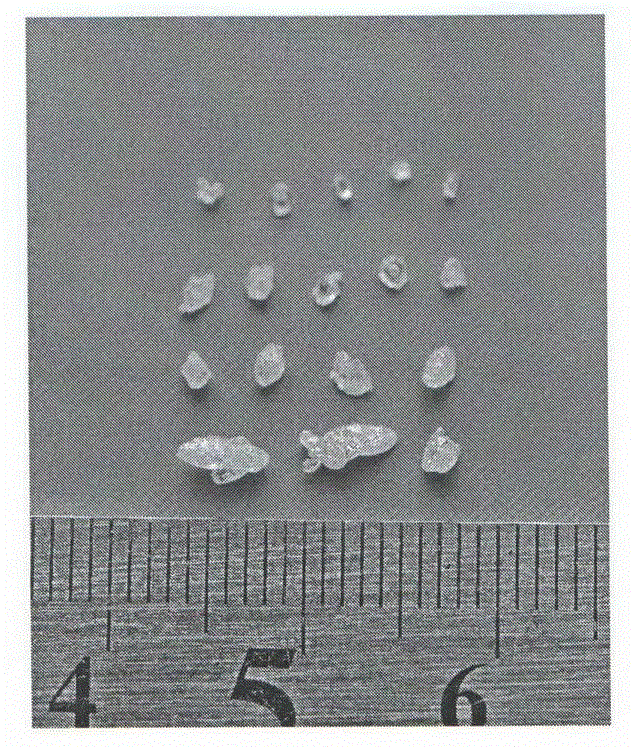

[0070] Then lower the temperature of the mixed melt to 750°C. At this time, the seed rod is quickly inserted into the liquid surface, and the temperature is slowly lowered to 650°C at a rate of 0.5°C / h, and the seed rod is lifted out of the liquid surface. There are aggregates, and then the temperature is lowered to room temperature at a rate of 10°C / h to obtain rubidium sodium chl...

Embodiment 3

[0075] According to the reaction formula: Rb 2 CO 3 +Na 2 CO 3 +2NaCl+6B 2 o 3 →2RbNa 2 B 6 o 10 Cl+2CO 2 ↑Synthesis of RbNa 2 B 6 o 10 Cl compounds:

[0076] Rb 2 CO 3 、Na 2 CO 3 , NaCl and B 2 o 3 Weigh the raw materials directly according to the molar ratio of 1:1:2:6, and combine the weighed raw materials with flux Na 2 O-PbO is mixed at a molar ratio of 1:3, where Na 2 The molar ratio of O to PbO is 1:2, put it into a Φ80mm×80mm open platinum crucible, heat up to 750°C, and keep the temperature for 20 hours to obtain a mixed melt;

[0077] Lower the temperature of the mixed melt to 730°C. At this time, quickly extend the seed rod under the liquid surface, slowly lower the temperature to 630°C at a rate of 5°C / h, and lift the seed rod out of the liquid surface. There will be Aggregates, and then lowered to room temperature at a rate of 8°C / h to obtain sodium rubidium chloroborate seed crystals;

[0078] Crystal growth in compound melts: RbNa will be ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com