A kind of silicon-containing alloy target material and preparation method thereof

A silicon alloy and target material technology, which is applied in the field of silicon-containing alloy target material and its preparation, can solve the problems that the density of CrSi products is difficult to meet the target material requirements, the purity is reduced, and the target material is polluted by impurities, and the microstructure is uniform. , high density and low content of impurity elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

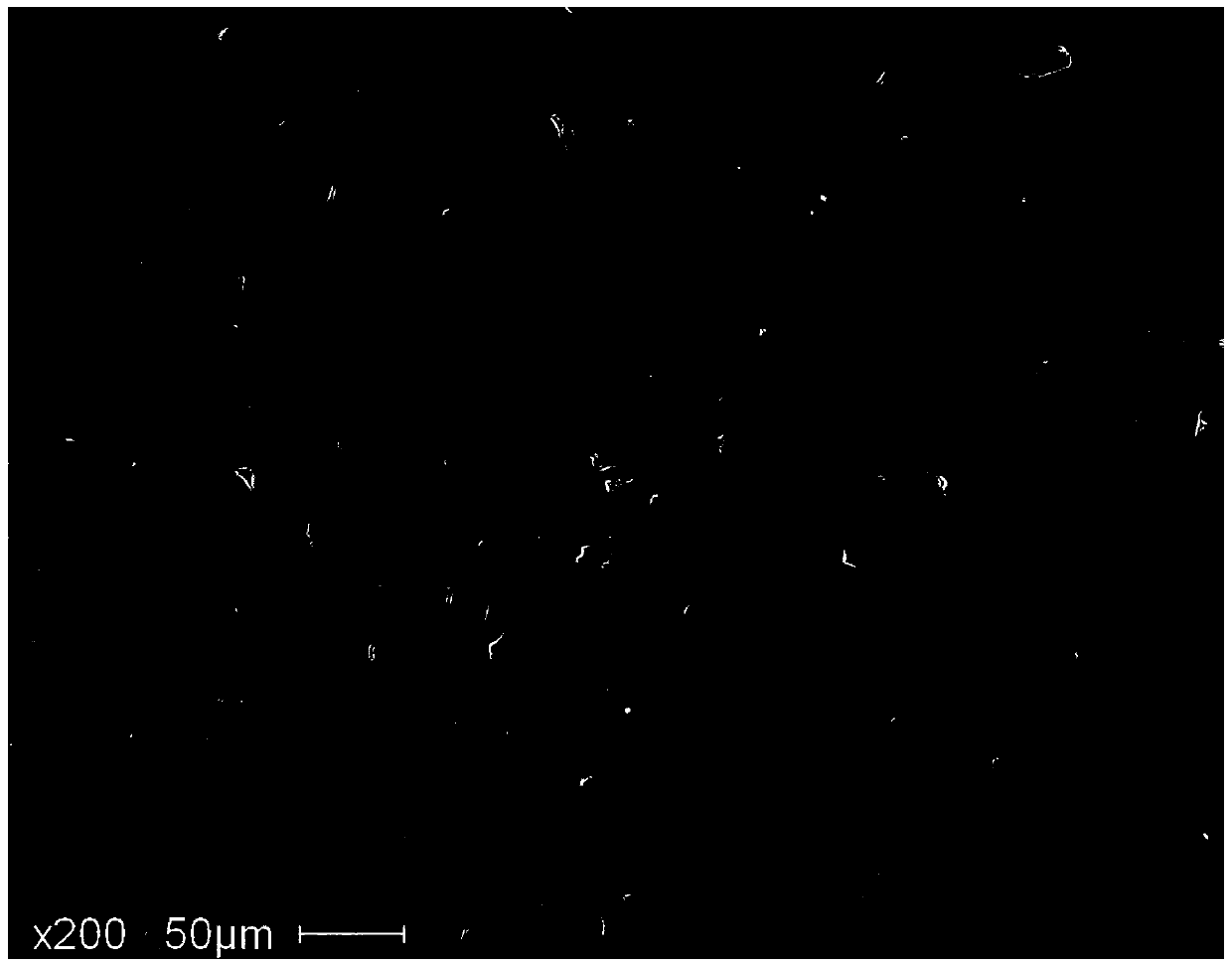

Image

Examples

Embodiment 1

[0056] The chromium-silicon alloy target includes the following atomic percentages: chromium 20%, silicon 80%;

[0057] The preparation method of the chromium-silicon target material of this example comprises the following steps:

[0058] Powder preparation steps: Weigh chromium powder with an average particle size of 35-40 μm and pure silicon powder with an average particle size of 45-75 μm according to the weight ratio corresponding to the atomic percentage of 20% chromium and 80% silicon, and mechanically alloy them by mechanical mixing process Chemical treatment, that is, mixing in a high-energy ball mill for 16 hours under the protection of an inert gas to obtain a uniformly mixed pre-alloyed powder; the average particle size of the obtained pre-alloyed powder is 40-50 μm;

[0059] Cold isostatic pressing treatment steps: put the pre-alloyed powder into a cold isostatic pressing forming mold for cold isostatic pressing treatment. During the treatment process, the cold iso...

Embodiment 2

[0065] The chromium-silicon alloy target includes the following atomic percentages: 70% chromium and 30% silicon.

[0066] The preparation method of the chromium-silicon target material of this example comprises the following steps:

[0067] Powder preparation steps: according to the weight ratio corresponding to 70% chromium and 30% silicon by atomic percentage, weigh chromium powder with an average particle size of 20-45 μm and silicon-chromium alloy powder with an average particle size of 35-45 μm, and mix them in a V-shaped Mix in the mixer for 3h to 10h, vacuumize for protection during the mixing process, and the vacuum degree is lower than 10 -4 Pa, thus obtaining a uniformly mixed pre-alloyed powder; the average particle size of the obtained pre-alloyed powder is 30-40 μm;

[0068] Cold isostatic pressing treatment step: put the pre-alloyed powder into a cold isostatic pressing forming mold for cold isostatic pressing treatment. During the treatment process, the cold ...

Embodiment 3

[0075] The chromium-silicon alloy target consists of the following atomic percentages: 50% chromium and 50% silicon. The preparation method of the chromium-silicon target material of this example comprises the following steps:

[0076] Powder preparation steps: according to the weight ratio corresponding to 50% chromium and 50% silicon by atomic percentage, weigh chromium powder with an average particle size of 20-45 μm and chromium-silicon alloy powder with an average particle size of 45-75 μm and mix them in a high-energy ball mill for 5 hours. Vacuumize and fill with high-purity argon for protection during the mixing process to obtain uniformly mixed pre-alloyed powder; the average particle size of the obtained pre-alloyed powder is 35-45 μm;

[0077] Cold isostatic pressing treatment step: put the pre-alloyed powder into a cold isostatic pressing forming mold for cold isostatic pressing treatment. During the treatment process, the cold isostatic pressing pressure is 200 MP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com