Method and preparation technology used for producing yellow phosphorus from low-grade phosphate ore

A low-grade, phosphate rock technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

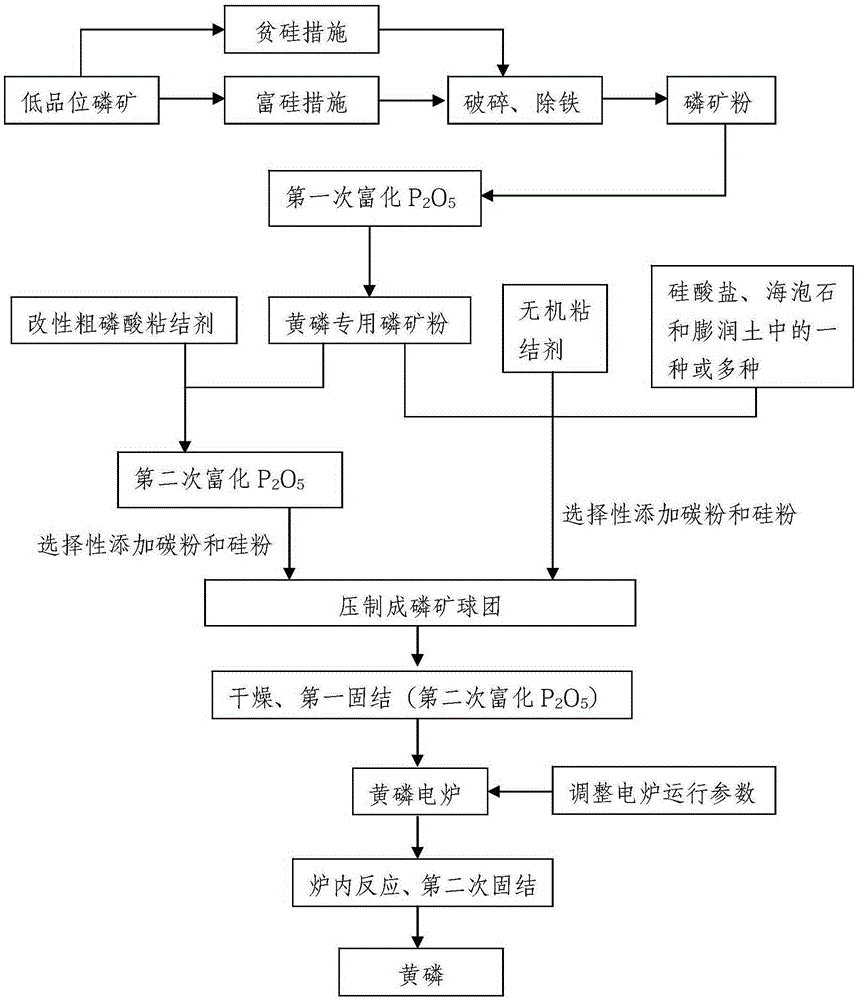

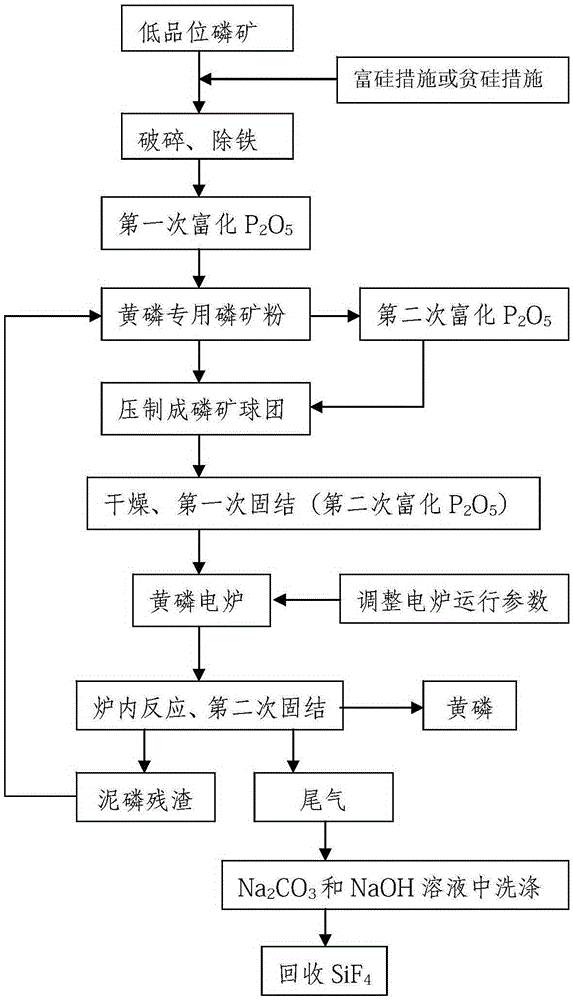

Method used

Image

Examples

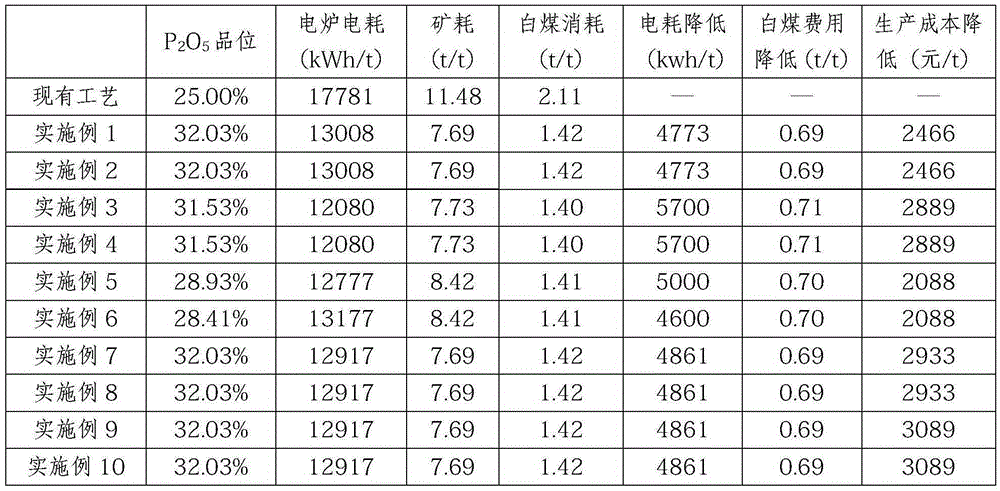

Embodiment 1

[0119] P with mining silicon-rich measures 2 o 5 Low-grade phosphate rock with a content of 22.5%, the first enrichment of P by reverse flotation 2 o 5 , to obtain the special phosphate rock powder for yellow phosphorus. Iron-containing compounds are removed during phosphate rock crushing. Add 4% modified crude phosphoric acid to the special phosphate rock powder for yellow phosphorus, and then perform 19MPa pressure to press into pellets. Phosphate ore pellets with a ball diameter of 5 mm to 30 mm are obtained by screening. After the phosphate rock pellets are consolidated by a consolidation machine, the sensible heat of the furnace gas in the yellow phosphorus electric furnace is used for secondary consolidation, and the final reaction is to obtain yellow phosphorus. Among them, the first consolidation temperature before entering the yellow phosphorus electric furnace is 650°C.

[0120] In this example, the phosphate rock powder P specially used for yellow phosphorus en...

Embodiment 2

[0123] P with mining silicon-rich measures 2 o 5 Low-grade phosphate rock with a content of 22.5%, the first enrichment of P by reverse flotation 2 o 5 , to obtain the special phosphate rock powder for yellow phosphorus. Iron-containing compounds are removed during phosphate rock crushing. Add 4% binder to the special phosphate rock powder for yellow phosphorus, and then perform 19MPa pressure to press into balls. Phosphate ore pellets with a ball diameter of 5 mm to 30 mm are obtained by screening. After the phosphate rock pellets are consolidated by a consolidation machine, the sensible heat of the furnace gas in the yellow phosphorus electric furnace is used for secondary consolidation, and the final reaction is to obtain yellow phosphorus. Among them, the first consolidation temperature before entering the yellow phosphorus electric furnace is 650°C.

[0124] In this example, the phosphate rock powder P specially used for yellow phosphorus enriched for the first time ...

Embodiment 3

[0127] with SiO 2 Content 35%, P 2 o 5 Low-grade phosphate rock with a content of 22.5% is obtained by positive flotation to obtain phosphate rock powder special for yellow phosphorus. Iron-containing compounds are removed during phosphate rock crushing. After drying the special phosphate rock powder for yellow phosphorus at 100-300°C (controlling the moisture content of the dry phosphate rock powder for yellow phosphorus to 0.6%), add the modified crude phosphoric acid. After stirring and homogenizing, press 14MPa pressure to form pellets, sieve to obtain phosphate rock powder pellets for yellow phosphorus with a ball diameter of 5mm to 30mm, and then consolidate the phosphate rock powder pellets for yellow phosphorus with a consolidation machine and use The sensible heat of the furnace gas in the yellow phosphorus electric furnace carries out secondary consolidation, and the final reaction produces yellow phosphorus. Among them, the first consolidation temperature before...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com