A Composite Channel Organic Field Effect Transistor

A composite channel and organic field technology, which is applied in the manufacturing of electrical components, electrical solid-state devices, semiconductor/solid-state devices, etc., can solve the problems of few interfaces and insufficient number of carriers, and achieve high switching current ratio and high current carrying. The effect of sub-mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

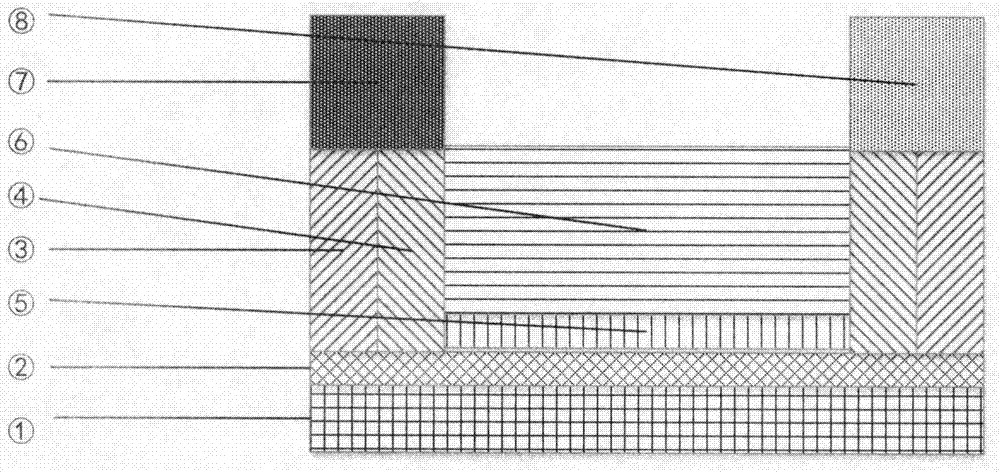

[0024] Such as figure 1 As shown, an organic field effect transistor with a composite channel, its preparation steps are as follows:

[0025] 1) The heavily doped silicon wafer was ultrasonically cleaned with acetone, ethanol, and deionized water for 30 minutes, and then dried in a glove box for 1 hour to clean the surface of the heavily doped silicon wafer;

[0026] 2) Place the above heavily doped silicon wafer in a UV / ozone environment for 120 minutes to obtain SiO 2 gate dielectric layer;

[0027] 3) On SiO 2 Positive photoresist is coated on the gate dielectric layer, and after pre-baking, exposure, development, and film hardening processes, ③ is obtained by photolithography. Pentacene active layer, control the evaporation rate to a vacuum of 1×10 -4 Pa; remove the glue after evaporation;

[0028] 4) Repeat step 3) to obtain ④ by photolithography, and the channel length is 200nm; then use the vacuum coating method to evaporate a 30nm thick C60 active layer on the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com