Preparation method of calcium phosphate bone cement simultaneously releasing zinc ions and silicate ions

A calcium phosphate bone cement, silicate ion technology, applied in medical science, prosthesis and other directions, can solve the problems of no induced osteogenesis, expensive growth factors, and the existence of sudden release phenomenon, so as to promote osteogenesis and improve bone formation. Bone properties, the effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

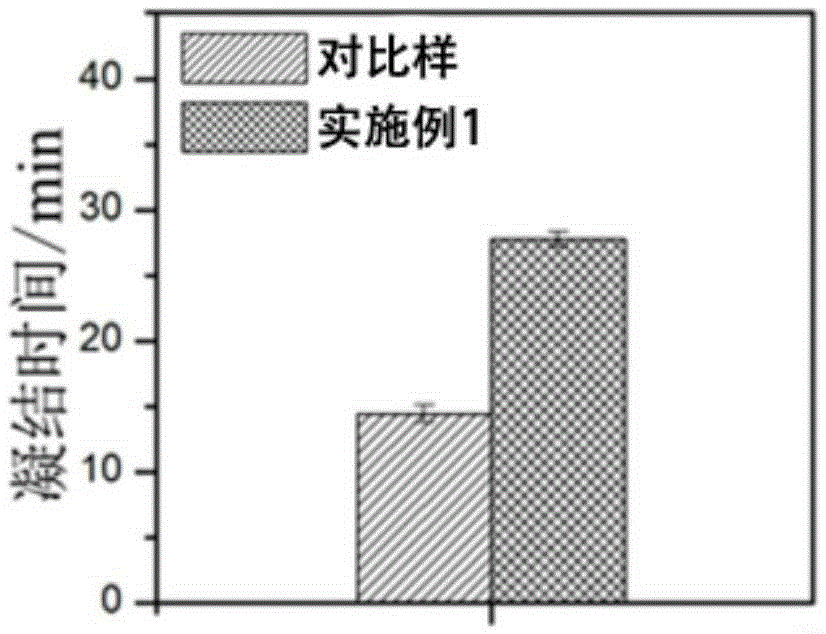

Embodiment 1

[0032] Select zinc silicate as an inorganic salt additive containing both zinc ions and silicate ions, and add it to the bone cement of the "partially crystalline calcium phosphate + anhydrous calcium hydrogen phosphate" system. The implementation steps include:

[0033] (11) A microwave hydrothermal method is used to prepare zinc silicate powder. Dissolve zinc acetate and ethyl orthosilicate in deionized water successively, the molar ratio of zinc to silicon is 2:1, and adjust the pH of the solution to 7 with ammonia. As the chemical reaction progresses, the solution gradually becomes a uniform white emulsion. The white emulsion was hydrothermally heated in a microwave at 160°C for 1 hour, and the white precipitate was washed with deionized water after the hydrothermal was completed and dried at 80°C to obtain the desired zinc silicate powder.

[0034] (12) Weigh 0.1 g of the zinc silicate powder prepared in step (11), weigh 0.9 g of the bone cement powder of the "partially cryst...

Embodiment 2

[0041] Select zinc-doped monocalcium silicate as an inorganic salt additive containing zinc ions and silicate ions, and add it to the bone cement of the "dihydrogen phosphate + α-tricalcium phosphate + calcium carbonate" system. The implementation steps include:

[0042] (11) A high-temperature solid-phase reaction method is used to prepare zinc-doped monocalcium silicate. Weigh a certain mass of zinc oxide and calcium silicate, where the molar ratio of zinc to calcium is 1:19. After the mixing is uniform, it is calcined at 1000° C. and kept for 4 hours to obtain the zinc-doped monocalcium silicate required for the experiment.

[0043] (12) Weigh 0.2 g of zinc-doped monocalcium silicate powder prepared in step (11), weigh 0.8 g of bone cement powder of the system of "dihydrogen phosphate + α-tricalcium phosphate + calcium carbonate", and It is evenly mixed. A 0.25mol / L disodium hydrogen phosphate solution was selected as the blending solution, and added to the zinc-doped monocalc...

Embodiment 3

[0050] Select zinc phosphate and dicalcium silicate as inorganic salt additives containing zinc ions and silicate ions, and add them to the "amorphous calcium phosphate + calcium hydrogen phosphate dihydrate" system bone cement. The implementation steps include:

[0051] (11) Weigh 0.05 g of dicalcium silicate, 0.05 g of zinc phosphate, and weigh 0.9 g of bone cement powder of the "amorphous calcium phosphate + calcium hydrogen phosphate dihydrate" system, and mix them evenly. A 0.1 mol / L potassium citrate solution was selected as the blending solution, and the liquid phase was added to the zinc phosphate and dicalcium silicate-containing bone cement powder prepared in this example according to the liquid-to-solid ratio of 0.4 mL / g, and blended Into a paste.

[0052] (12) Put the pastes prepared in step (11) into injectable instruments, respectively, and form and solidify the bone cement after injection.

[0053] Comparison sample:

[0054] (21) Weigh 1 g of bone cement powder of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com