Preparation method of anti-oxidative natural gas engine lubricating oil

A natural gas and engine technology, applied in the field of preparation of natural gas engine lubricating oil, can solve the problems of low oxidation resistance and nitrification resistance, and achieve the effects of good nitrification resistance, good oxidation resistance and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

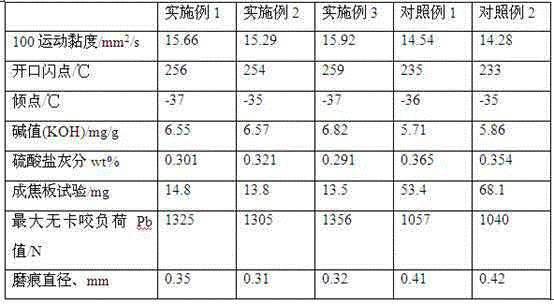

Examples

Embodiment 1

[0031] Step 1: In parts by weight, take the kinematic viscosity at 100°C as 1-5mm 2 100 parts of mineral oil per s, 5 parts of epoxidized soybean oil, and 3 parts of α-olefin oxide, after mixing evenly, heat and reflux for heat preservation at a heating temperature of 40°C, reflux for 1 hour, and let cool;

[0032]Step 2: Add 5 parts of hydrogenated castor oil, 1 part of dibutyl succinate, 0.3 part of sorbitan monooleate to the mixture prepared in step 1, and the range of alkali value is 250-300mgKOH / g sulfurized calcium alkylphenate 0.4 part, coconut oil fatty acid diethanolamide 0.2 part, rust inhibitor 0.1 part, cloud removing agent 0.2 part, demulsifier 0.1 part, metal deactivator 0.3 part, friction modifier 0.1 part , 0.4 parts of pour point depressant, 0.2 part of defoamer, 0.2 part of co-solvent, 0.2 part of corrosion inhibitor, 0.2 part of dye, 0.2 part of extreme pressure agent. 2 hours, let cool and serve.

Embodiment 2

[0034] Step 1: In parts by weight, take the kinematic viscosity at 100°C as 1-5mm 2 150 parts of mineral oil per s, 10 parts of epoxidized soybean oil, and 5 parts of α-olefin oxide, after mixing evenly, heat and reflux for heat preservation at a heating temperature of 60°C, reflux for 2 hours, and let cool;

[0035] Step 2: Add 10 parts of hydrogenated castor oil, 2 parts of dibutyl succinate, 1 part of sorbitan monooleate to the mixture prepared in step 1, and the range of alkali value is 250-300mgKOH / g of sulfurized calcium alkylphenate 0.6 part, coconut oil fatty acid diethanolamide 0.4 part, rust inhibitor 0.1 part, cloud removing agent 0.2 part, demulsifier 0.1 part, metal deactivator 0.3 part, friction modifier 0.1 part , 0.4 parts of pour point depressant, 0.2 part of defoamer, 0.2 part of co-solvent, 0.2 part of corrosion inhibitor, 0.2 part of dye, 0.2 part of extreme pressure agent, mix well, heat and reflux heat preservation, heating temperature 60 ℃, reflux heat ...

Embodiment 3

[0037] Step 1: In parts by weight, take the kinematic viscosity at 100°C as 1-5mm 2 120 parts of mineral oil per s, 8 parts of epoxidized soybean oil, and 4 parts of α-olefin oxide, after mixing evenly, heat and reflux for heat preservation at a heating temperature of 50°C, reflux for 2 hours, and let cool;

[0038] Step 2: Add 8 parts of hydrogenated castor oil, 2 parts of dibutyl succinate, 0.5 part of sorbitan monooleate to the mixture prepared in step 1, and the range of alkali value is 250-300mgKOH / g of sulfurized calcium alkylphenate 0.5 part, coconut oil fatty acid diethanolamide 0.3 part, rust inhibitor 0.1 part, cloud removing agent 0.2 part, demulsifier 0.1 part, metal deactivator 0.3 part, friction modifier 0.1 part , 0.4 parts of pour point depressant, 0.2 parts of defoamer, 0.2 part of co-solvent, 0.2 part of corrosion inhibitor, 0.2 part of dye, 0.2 part of extreme pressure agent, mix well, heat and reflux heat preservation, heating temperature 55 ℃, reflux heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com