A kind of solid semi-crystalline unsaturated polyurethane prepolymer and preparation method thereof

A polyurethane prepolymer, unsaturated technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of material filamentation, filamentous appearance and material adhesion, etc., to achieve guaranteed The effect of the curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

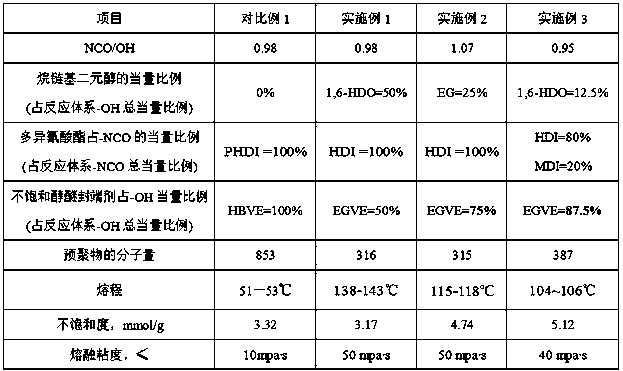

Embodiment 1

[0030] Keep nitrogen and stirring state, add 84.1g hexamethylene diisocyanate monomer (HDI), 0.05g dibutyltin dilaurate catalyst and 0.01g hydroquinone monomethyl ether polymerization inhibitor In a nitrogen-filled reactor, slowly heat up to 60°C, slowly add 29.5g of 1,6-hexanediol (1,6-HDO) dropwise, and control the rate of addition during the dropping process to prevent the temperature of the reaction system from exceeding 80°C, slowly heat up to 120°C, keep warm for 1-2 hours to complete the first-stage reaction; slowly drop 44.1g of vinyl glycol ether (EGVE) into the first-stage reaction system, and control the rate of addition during the dropping process to prevent the temperature of the reaction system from exceeding 130°C ; After adding vinyl glycol ether, slowly raise the temperature and keep the temperature at 150°C~160°C, keep it warm for 1 hour and then discharge. After cooling at room temperature, it will be a milky white brittle hard substance with a melting range ...

Embodiment 2

[0032] Keep nitrogen and stirring state, add 67.3g hexamethylene diisocyanate monomer (HDI), 0.04g dibutyltin dilaurate catalyst and 0.01g hydroquinone monomethyl ether polymerization inhibitor In a reaction kettle with nitrogen gas, slowly raise the temperature to 60°C, slowly add 6.2g of ethylene glycol dropwise, control the dropping rate during the dropping process to prevent the temperature of the reaction system from exceeding 80°C, slowly raise the temperature to 120°C, and keep warm for 1-2 hours to complete the first step. stage reaction; slowly add 52.9g of vinyl glycol ether (EGVE) dropwise into the first stage reaction system, and control the rate of addition during the dropping process to avoid the temperature of the reaction system from exceeding 125°C; after the addition of vinyl glycol ether, slowly Raise the temperature and keep the temperature at 125°C~130°C, keep it warm for 1 hour, and discharge the material. After cooling at room temperature, it is a white, ...

Embodiment 3

[0034] Keep nitrogen and stirring state, 108.1g hexamethylene diisocyanate monomer (HDI), 40.3g 2,4-diphenylmethane diisocyanate monomer (2,4-MDI), dibutyltin dilaurate catalyst 0.07g and 0.01g of hydroquinone monomethyl ether polymerization inhibitor were simultaneously added to a reactor with a stirring paddle that could pass through nitrogen, and the temperature was slowly raised to 60°C, and 12.2g of 1,6-hexanediol (1.6- HDO), the dropping process controls the dropping rate to avoid the temperature of the reaction system exceeding 80°C, slowly warming up to 120°C, and keeping warm for 1-2 hours to complete the first stage reaction; slowly drop 123.8g of vinyl glycol ether (EGVE) into In the first stage of the reaction system, the dropping rate is controlled during the dropping process to prevent the temperature of the reaction system from exceeding 125°C; after the addition of vinyl glycol ether, the temperature rises slowly and the temperature is kept at 120°C-125°C. Whit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| degree of unsaturation | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com