Resource utilization method of household garbage incineration residue sorting tailing

A domestic waste incineration and waste incineration technology, which is applied in the field of comprehensive utilization of solid waste resources, can solve problems affecting the strength of road construction materials, the impact of clinker calcination process, and large dry shrinkage of block products, so as to achieve resource utilization and large-scale treatment, high slag addition ratio, and low product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

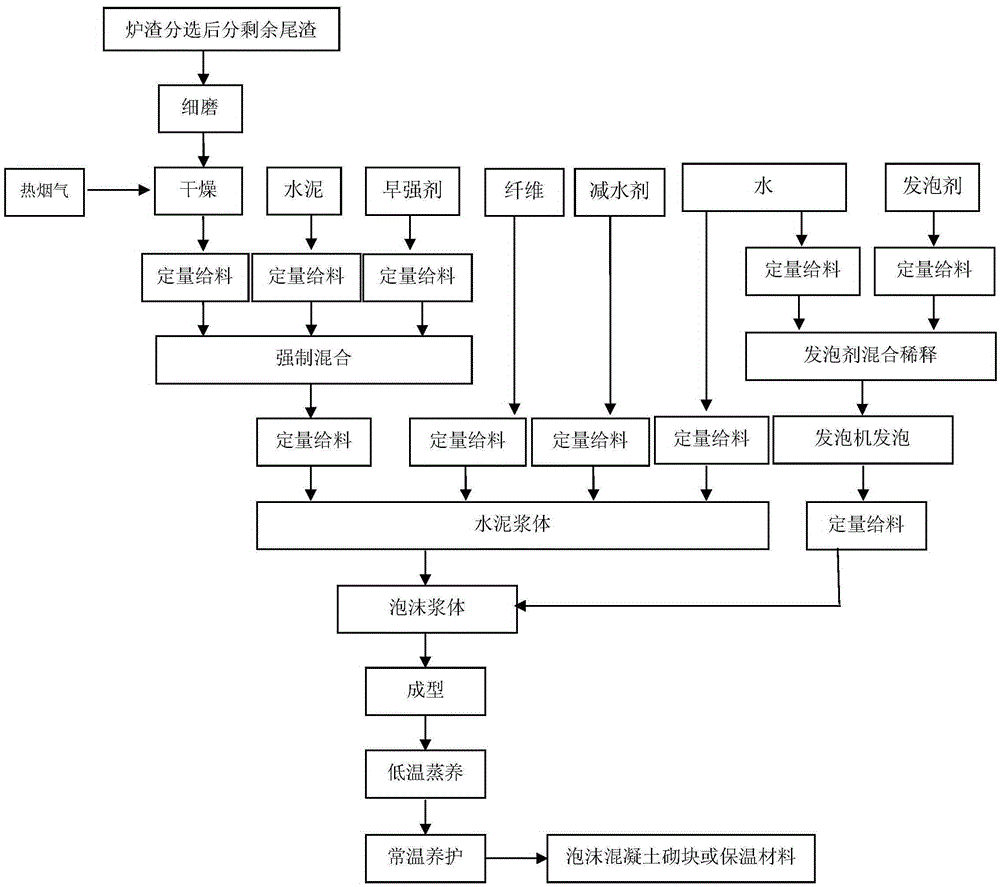

Method used

Image

Examples

Embodiment 1

[0048] Prepare foam concrete blocks as follows:

[0049] 1) Fine grinding: Grinding the remaining tailings after sorting out iron, aluminum, copper, zinc, gold, silver and other metals from the waste incineration plant slag, the particle size is 700cm in specific surface area 2 / g; The finely ground tailings powder is directly dried with hot flue gas to obtain sorted tailings micropowder with a moisture content of 1% and free CaO and MgO contents <1%.

[0050] 2) Mixture preparation: dry-mix the fine powder of sorted tailings with cement and early strength agent in proportion, and the mixing time is 10 minutes. Ordinary Portland cement is used for cement; the ratio of sorted tailings micropowder:cement is 3:7; the early strength agent is sodium silicate and triethanolamine compounded at 1:1, and the addition ratio is cement and sorted tailings micropowder dry basis 1% of the total amount.

[0051] 3) Foam preparation: Dilute the foaming agent 50 times with water and stir sli...

Embodiment 2

[0058] Prepare foam concrete blocks as follows:

[0059] 1) Fine grinding: Grinding the remaining tailings after sorting out iron, aluminum, copper, zinc, gold, silver and other metals from the waste incineration plant slag, the particle size is 400cm in specific surface area 2 / g; The finely ground tailings powder is directly dried with hot flue gas to obtain sorted tailings micropowder with a moisture content of 0.5% and free CaO and MgO contents <1%.

[0060] 2) Mixture preparation: dry-mix the fine powder of sorted tailings with cement and early strength agent in proportion, and the mixing time is 5 minutes. Ordinary Portland cement is used for cement; the ratio of sorted tailings micropowder:cement is 4:6; the early strength agent is calcium chloride, and the addition ratio is 3% of the total dry basis of cement and sorted tailings micropowder.

[0061] 3) Foam preparation: Dilute the foaming agent 30 times with water and stir slightly evenly, and then use a cement foami...

Embodiment 3

[0068] Prepare the insulation material as follows:

[0069] 1) Fine grinding: Grinding the remaining tailings after sorting out iron, aluminum, copper, zinc, gold, silver and other metals from the waste incineration plant slag, the particle size is 500cm in specific surface area 2 / g; The finely ground tailings powder is directly dried with hot flue gas to obtain sorted tailings micropowder with a moisture content of 0.3% and free CaO and MgO contents <1%.

[0070] 2) Mixture preparation: dry-mix the sorted tailings fine powder with cement and early strength agent in proportion, and the mixing time is 7 minutes. Ordinary Portland cement is used for cement; the ratio of sorted tailings powder: cement is 1:19; the early strength agent is sodium sulfate and urea compounded at 1:1, and the addition ratio is the total amount of cement and sorted tailings powder on a dry basis 2%.

[0071] 3) Foam preparation: Dilute the foaming agent 40 times with water and stir slightly evenly, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com