A device for clean production of tungsten disulfide

A tungsten disulfide, clean production technology, applied in tungsten compounds, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of difficult continuous production, low equipment investment, low yield, etc., achieve clean and efficient production, reduce adhesion performance, to avoid the effect of the tower opening being too large

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

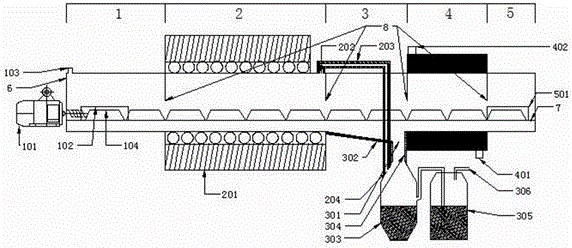

[0013] Such as figure 1 As shown, a specific embodiment of the tungsten disulfide clean production device of the present invention includes the following: it is composed of a box-type reaction tube 6 and a sulfur recovery tower 303. The box-type reaction tube is divided into a feed zone 1 and a reaction zone 2. , low temperature zone 3, cooling zone 4 and discharge zone 5, there is a push boat track 7 in the box-type reaction tube, and push boats 104 are arranged on the track, an inert gas inlet 103 is arranged at the upper end of the feed zone 1, and a feed port is arranged at the side 102, the head is connected to the electric pusher 101; the reaction zone 2 is heated and controlled by the resistance furnace 201, and there is a gas outlet 202 on the top of the reaction zone at the lower end of the air flow, which is connected to the sulfur recovery tower 303 through the resistance wire insulation pipe 203, and the gas passes through the gas inlet 204 Enter; the sulfur outlet...

Embodiment 2

[0015] Same as in Example 1, the slope 301 on the side of the sulfur outlet in the low temperature zone has a slope of 10 degrees, and the surface of the slope is sprayed with 2.5 mm of tungsten disulfide. The device is used for continuous production for 5 months without closure.

Embodiment 3

[0017] Same as in Example 1, the slope 301 on both sides of the sulfur outlet in the low temperature zone has a slope of 15 degrees, and 5.0 mm of tungsten disulfide is sprayed on the surface of the slope. The device is used for continuous production for August without closure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com