Foam-like low-temperature SCR catalyst and preparation method thereof

An SCR catalyst and foam-like technology, which is applied in the field of foam-like low-temperature SCR catalyst and its preparation, can solve the problems of difficult mixing of flue gas and reducing agent, lower utilization rate of catalyst and low utilization rate of reducing agent, etc. Effects of denitration efficiency, good thermal stability and anti-sulfur and water resistance, excellent low temperature activity and denitration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

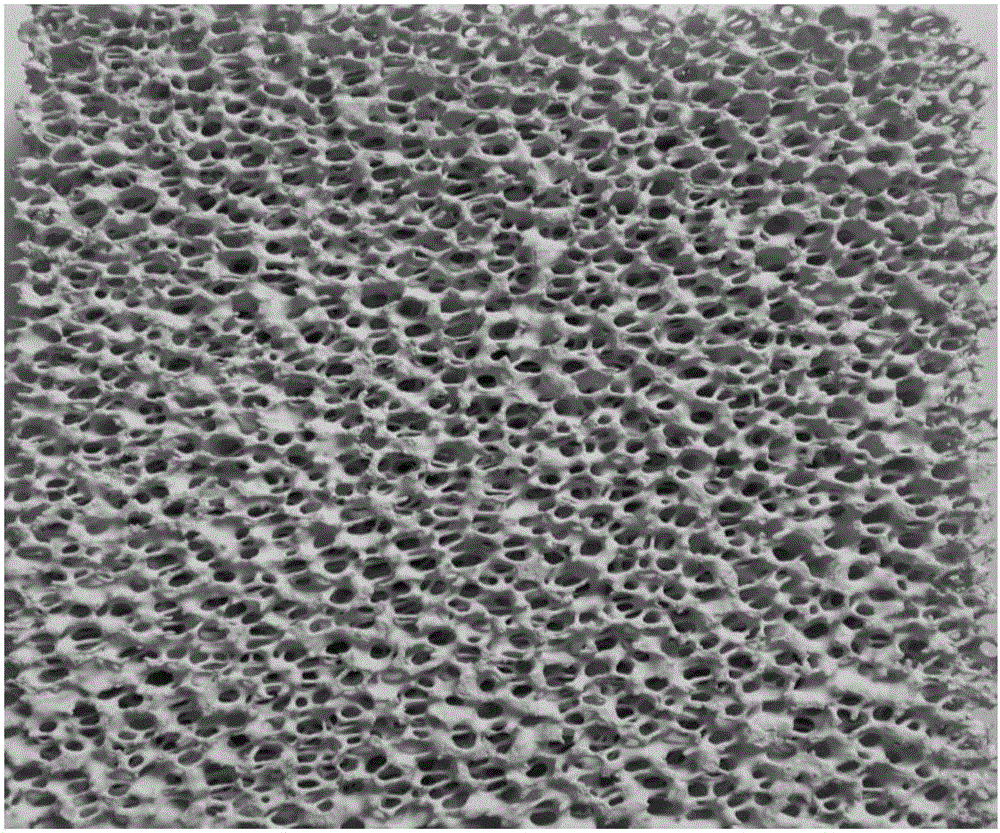

Image

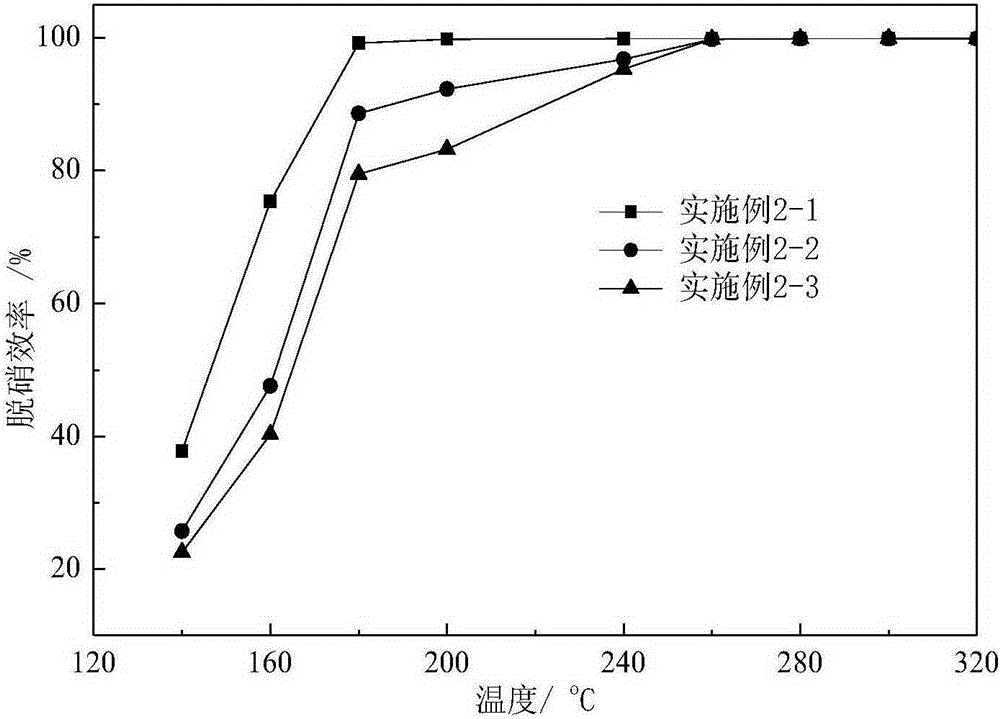

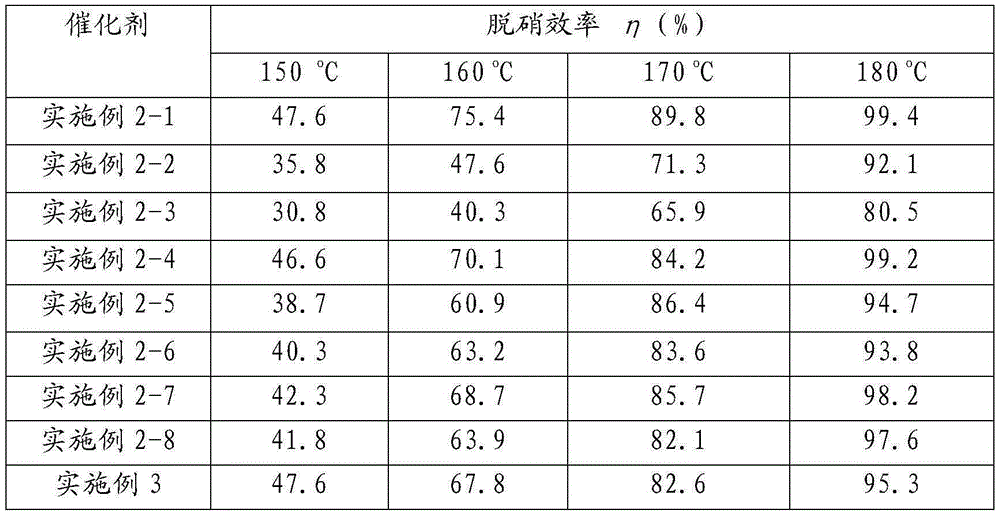

Examples

Embodiment 1-1

[0038] Add 7.5Kg of deionized water to the reaction kettle and heat it to 50°C, add 1.35Kg of oxalic acid and stir until dissolved, slowly add 0.24Kg of ammonium metavanadate, add 0.45Kg of ammonium heptamolybdate after 1-10min, and add 0.45Kg of ammonium heptamolybdate after stirring for 20min and 0.08Kg manganese nitrate, stirring for 1.5h, adding 0.03Kg ammonium sulfate, stirring for 30min, to obtain an impregnation solution of active components.

[0039] Add 6Kg TiO to the active ingredient impregnation solution 2 The powder was stirred to a slurry state, and ultrasonically dispersed for 1.5 hours under stirring conditions to obtain a low-temperature SCR catalyst slurry; the low-temperature SCR catalyst slurry was dried at 250 °C for 3.0 hours, then crushed, and then calcined at 450 °C in an air flow for 3.5 hours. , pulverized to 300 mesh to obtain active coating powder 1-1, where V 2 O 5 , MoO 3 , MnO 2 and SO 2 The loadings relative to the substrate were 3%, 6%, 0....

Embodiment 1-2

[0041] Compared with Example 1-1: the mass of oxalic acid was changed from 1.35Kg to 0.9Kg, the mass of ammonium metavanadate was changed from 0.24Kg to 0.16Kg, and the rest of the process was the same as that of Example 1-1, to obtain active coating powder 1-2 , where V 2 O 5 , MoO 3 , MnO 2 and SO 2 The loadings relative to the substrate were 2%, 6%, 0.5% and 0.25%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com