Ag/AgCl loaded sodium nickel phosphate composite photocatalytic material as well as preparation method and application thereof

A technology of composite photocatalysis and sodium nickel phosphate, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., to achieve good photocatalytic activity, easy to popularize and use, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) First, prepare Na by high-temperature solid-phase method 4 Ni 3 P 4 o 15 :

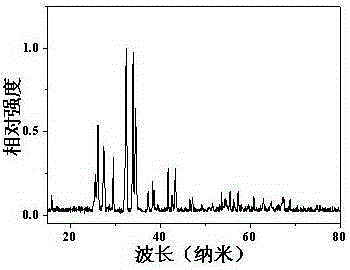

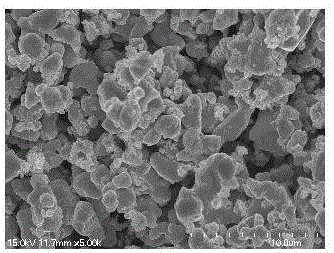

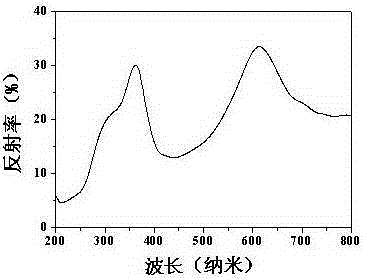

[0044] According to the chemical formula Na 4 Ni 3 P 4 o 15 The stoichiometric ratio of each element in, respectively weighed sodium carbonate Na 2 CO 3 : 0.848 g, nickel oxide NiO: 0.897 g, phosphorus pentoxide P 2 o 5 : 1.136 g, ground and mixed uniformly in an agate mortar; then, pre-calcined in a muffle furnace at 600° C. for 5 hours in an air atmosphere, cooled naturally, and took out the sample. Next, fully mix and grind the samples from the previous step again, calcinate them at 1000°C for 6 hours in an air atmosphere, cool to room temperature, take them out and grind them thoroughly to obtain Na 4 Ni 3 P 4 o 15 Photocatalyst powder.

[0045] (2) Second, prepare Ag / AgCl loaded Na 4 Ni 3 P 4 o 15 Composite photocatalytic materials:

[0046] Take 0.5g of Na 4 Ni 3 P 4 o 15 The particles were added to 30mL of deionized water, sonicated for 10 minutes; then mixed ...

Embodiment 2

[0054] (1) First, prepare Na by high-temperature solid-phase method 4 Ni 3 P 4 o 15 :

[0055] According to the chemical formula Na 4 Ni 3 P 4 o 15 The stoichiometric ratio of each element in , respectively weighed sodium oxide Na 2 O: 0.496 g, basic nickel carbonate NiCO 3 2Ni(OH) 2 4H 2 O: 4.514 g, ammonium dihydrogen phosphate NH 4 h 2 PO 4 : 1.841 g, ground and mixed evenly in an agate mortar; then pre-calcined in a muffle furnace at 550°C for 8 hours in an air atmosphere, cooled naturally, and took out the sample; then, fully mixed and ground the previous sample again , in an air atmosphere, calcined at 950°C for 10 hours, cooled to room temperature, taken out and thoroughly ground to obtain Na 4 Ni 3 P 4 o 15 Photocatalyst powder.

[0056] (2) Second, prepare Ag / AgCl loaded Na 4 Ni 3 P 4 o 15 Composite photocatalytic materials:

[0057] Take 0.5g of Na 4 Ni 3 P 4 o 15 The particles were added to 30mL of deionized water, sonicated for 10 minutes...

Embodiment 3

[0060] (1) First, prepare Na by high-temperature solid-phase method 4 Ni 3 P 4 o 15 :

[0061] According to the chemical formula Na 4 Ni 3 P 4 o 15 The stoichiometric ratio of each element in the formula, respectively weighed sodium bicarbonate NaHCO 3 : 1.344 g, nickel oxide Ni 2 o 3 : 0.992 g, phosphoric acid H 3 PO 4 : 1.568 g, ground and mixed in an agate mortar, pre-calcined in an air atmosphere at 400 ° C for 12 hours in a muffle furnace, cooled naturally, and took out the sample; again fully mixed and ground the aforementioned sample mixture, Calcined at 850°C for 14 hours in an air atmosphere, cooled to room temperature, taken out and thoroughly ground to obtain Na 4 Ni 3 P 4 o 15 Photocatalyst powder.

[0062] (2) Second, prepare Ag / AgCl loaded Na 4 Ni 3 P 4 o 15 Composite photocatalytic materials:

[0063] Take 0.5g of Na 4 Ni 3 P 4 o 15 The particles were added to 30 mL of deionized water, sonicated for 10 minutes, and then mixed with 10 mL ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com