Composite volatile corrosion inhibitor and application thereof in anticorrosion protection of large equipment

A gas-phase corrosion inhibitor, anti-corrosion and anti-rust technology, which is applied in anti-rust materials and anti-corrosion fields, can solve the problems of increasing the difficulty and cost of protection work, increasing the difficulty of airtightness, and corrosion of metal materials, so as to improve the overall technical level and ability of support, The effect of equipment corrosion rate reduction and high-efficiency corrosion protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

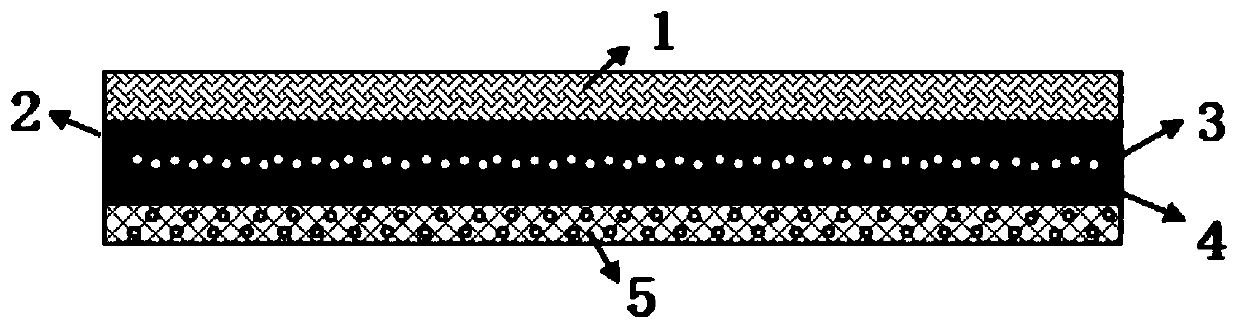

Image

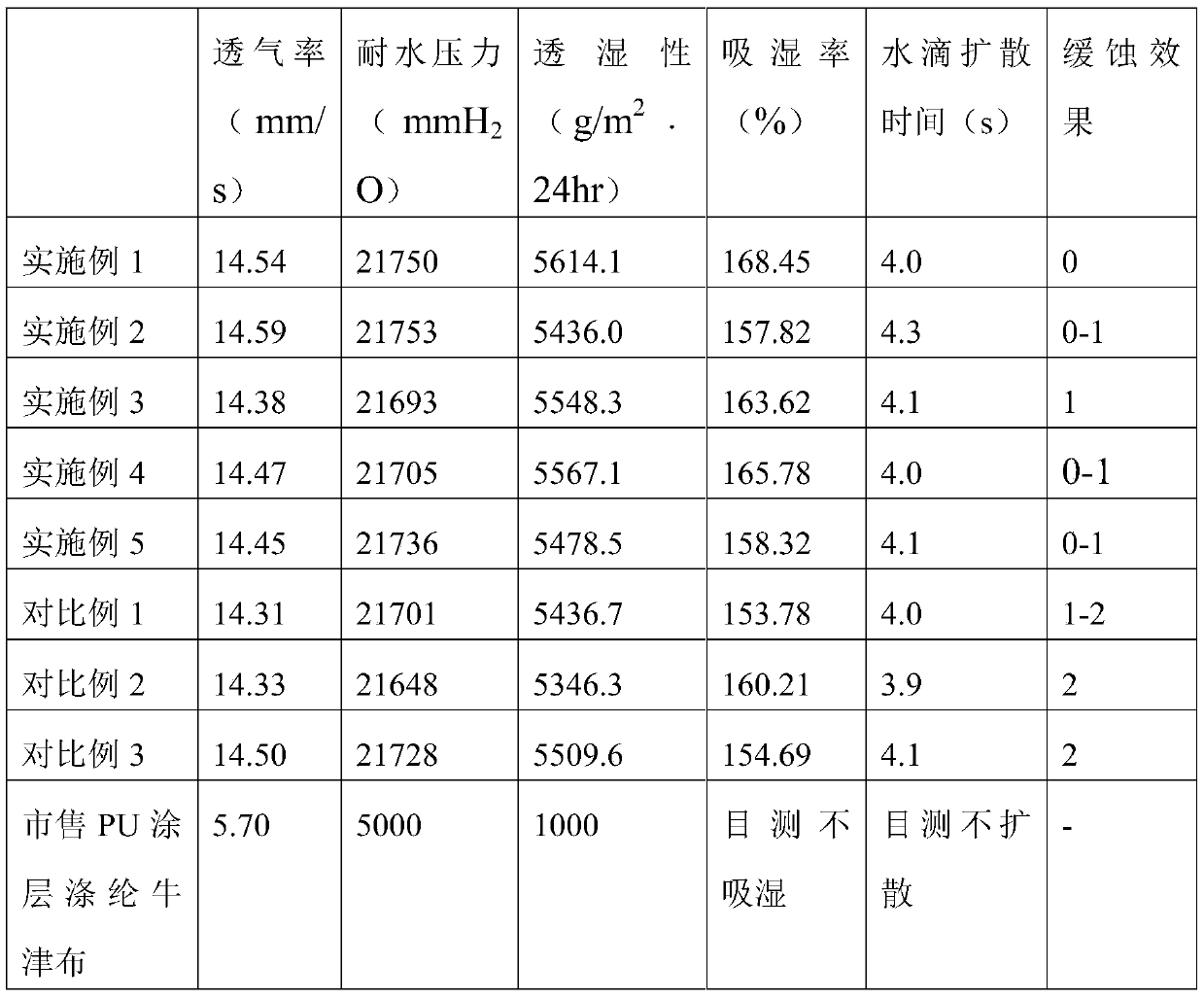

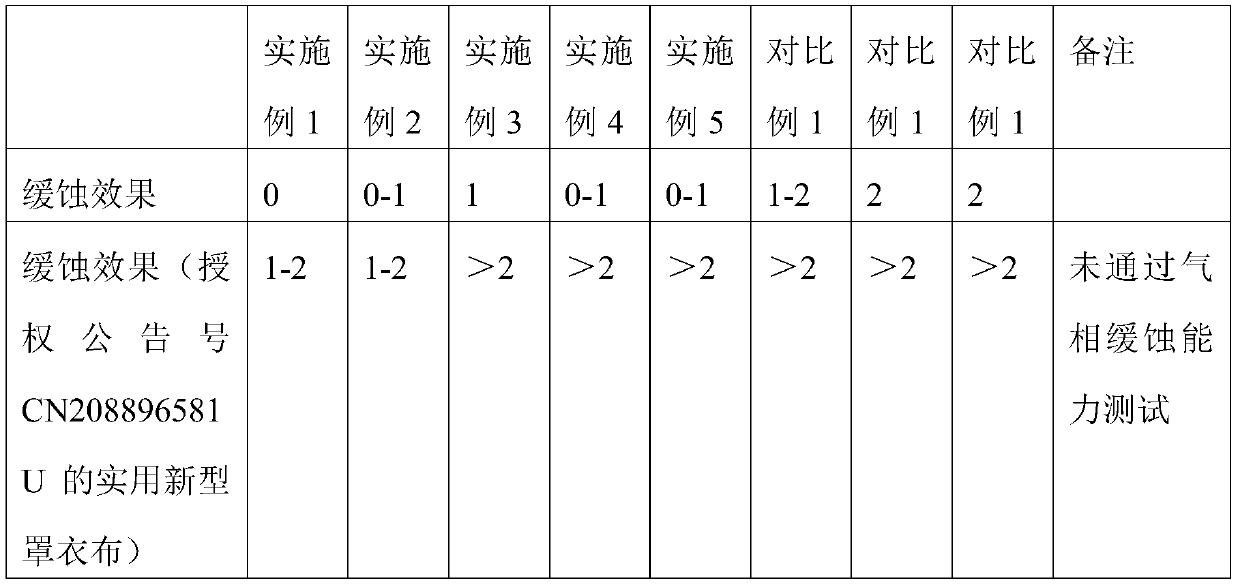

Examples

Embodiment 1

[0030] Embodiment 1 Composite vapor phase corrosion inhibitor (1)

[0031] Sodium tungstate: 25g, sodium molybdate: 25g, 2-methylimidazole: 25g, urea 25g, total mass 100g.

Embodiment 2

[0032] Embodiment 2 Composite vapor phase corrosion inhibitor (2)

[0033] Sodium tungstate: 20g, sodium molybdate: 40g, 2-methylimidazole: 35g, urea 5g, the total mass is 100g.

Embodiment 3

[0034] Embodiment 3 Composite vapor phase corrosion inhibitor (3)

[0035] Sodium tungstate: 25g, sodium molybdate: 30g, 2-methylimidazole: 25g, urea 20g, the total mass is 100g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Air permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com