Graft polymerization type light stabilizer and preparation method thereof

A technology of light stabilizer and graft polymerization, which is applied in the field of graft polymerization type light stabilizer and its preparation, can solve the problems of small molecular weight, poor compatibility of polymer materials, intolerant of extraction, etc., and achieves low volatility , Superior polymer compatibility, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

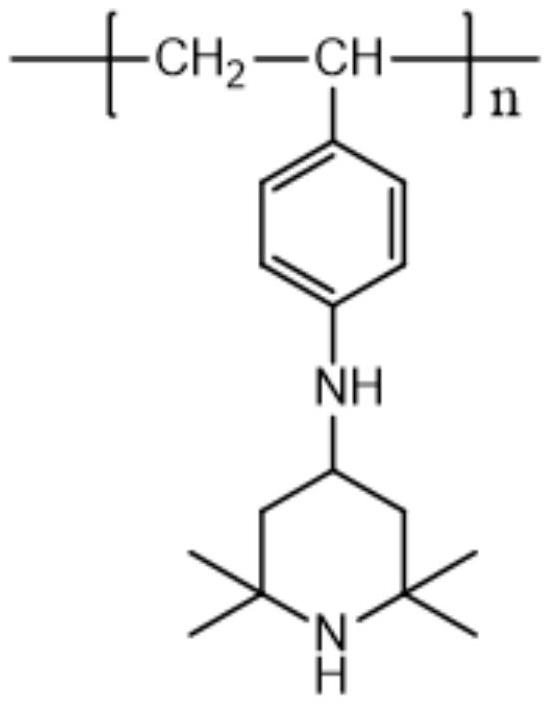

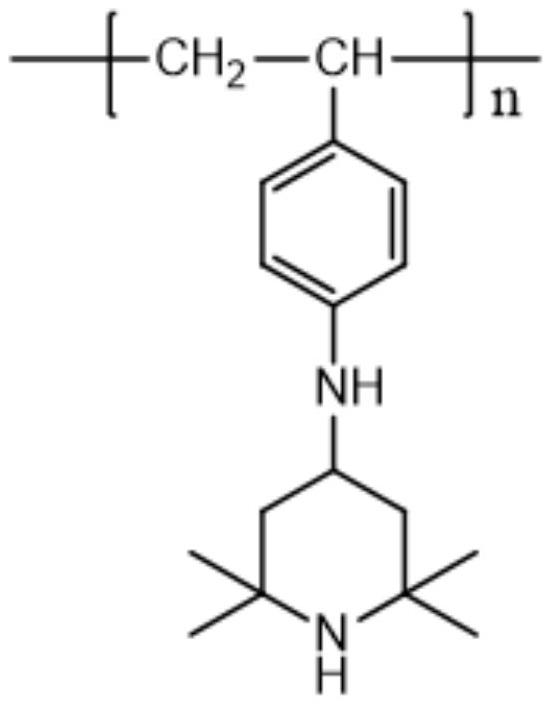

Image

Examples

Embodiment 1

[0028] A preparation method of a graft polymerization type light stabilizer, comprising the following steps:

[0029] Add 75.2g intermediate 2,2,6,6-tetramethyl-N-(4-vinylphenyl)piperidin-4-amine, 225g xylene, 0.38g titanocene dichloride to the polymerization reactor and 0.076g co-catalyst MAO, after replacing the air with nitrogen, start stirring to make the materials fully mixed, then feed nitrogen to make the pressure in the kettle reach 1.2Mpa, turn on the heating system and raise the temperature to 120°C for 5 hours, then cool down and wash with water, divide the water After that, 0.75 g of activated carbon was added to the organic layer for dehydration and decolorization, filtered, and the filtrate was directly distilled to obtain 69.8 g of the graft polymerization type light stabilizer, and the yield of this step was 92.8%.

Embodiment 2

[0031] A preparation method of a graft polymerization type light stabilizer, comprising the following steps:

[0032] Add 152.6g intermediate 2,2,6,6-tetramethyl-N-(4-vinylphenyl)piperidin-4-amine, 535g xylene, 0.91g titanocene dichloride to the polymerization reactor and 0.16g co-catalyst MAO, after replacing the air with nitrogen, start stirring to make the materials fully mixed, then feed nitrogen to make the pressure in the kettle reach 2.0Mpa, turn on the heating system and raise the temperature to 140°C for 6 hours, then cool down and wash with water, divide the water Then add 1.55g of activated carbon to the organic layer for dehydration and decolorization, filter, and distill the filtrate to obtain 140.3g of the graft polymerization light stabilizer, the yield of this step is 91.9%.

Embodiment 3

[0034] A preparation method of a graft polymerization type light stabilizer, comprising the following steps:

[0035] Add 233.7g intermediate 2,2,6,6-tetramethyl-N-(4-vinylphenyl)piperidin-4-amine, 930g xylene, 2.33g dichlorozirconocene to the polymerization reactor and 0.62g co-catalyst EAO, after replacing the air with nitrogen, turn on the stirring to make the materials fully mixed, then pass in nitrogen to make the pressure in the kettle reach 2.5Mpa, turn on the heating system and raise the temperature to 150°C for 6 hours, then cool down and wash with water, divide the water Then add 2.5 g of activated carbon to the organic layer for dehydration and decolorization, filter, and distill the filtrate to obtain 209.8 g of the graft polymerization light stabilizer, and the yield of this step is 89.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com