Low-polymerization type hindered amine light stabilizer and preparation method thereof

A technology of hindered amine light stabilizer and light stabilizer, which is applied in the manufacture of rayon, one-component polyolefin rayon, chemical characteristics of fibers, etc., can solve the problem of easy failure of effective groups, poor light stability and low volatility and other problems, to achieve the effect of low volatility, good compatibility and good purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

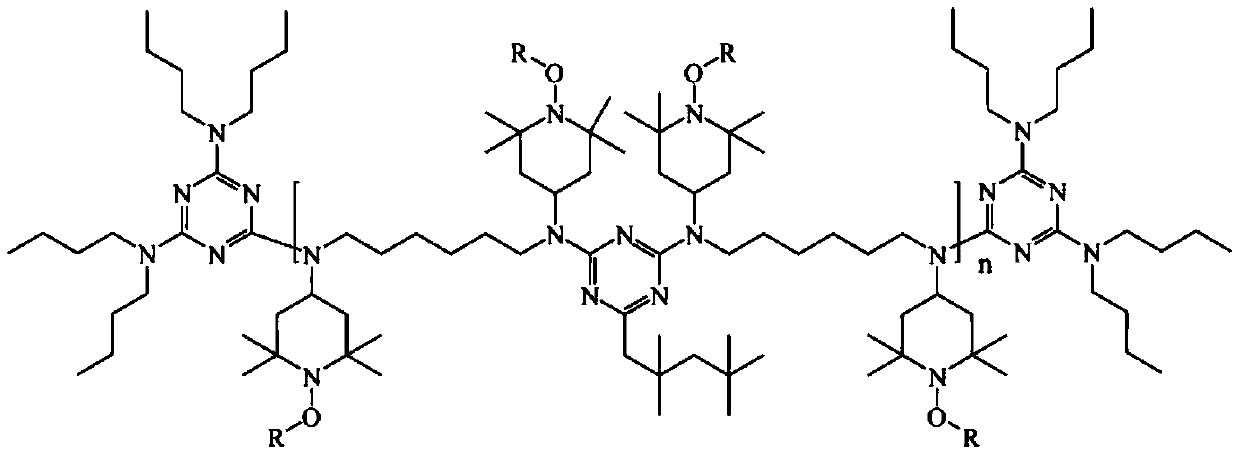

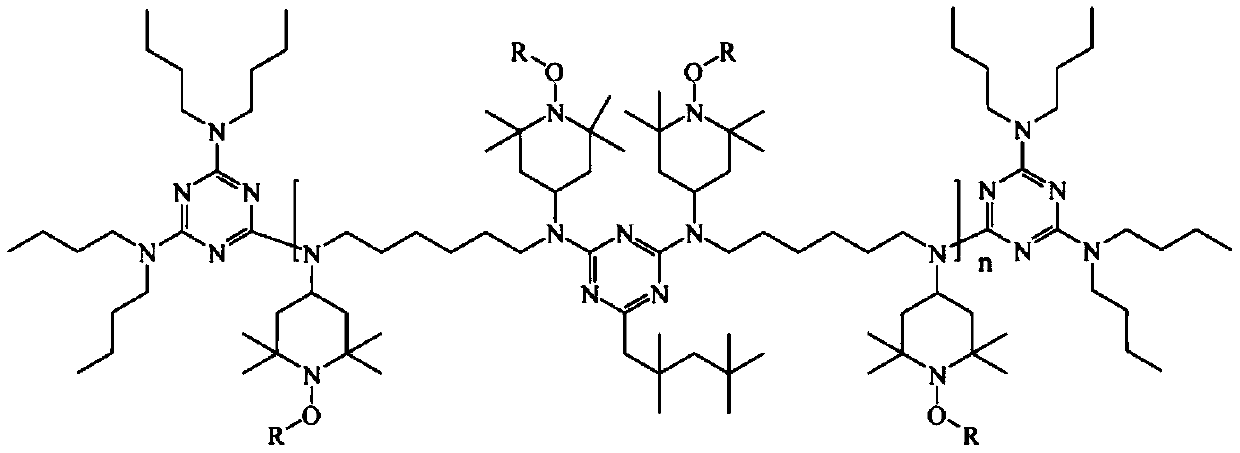

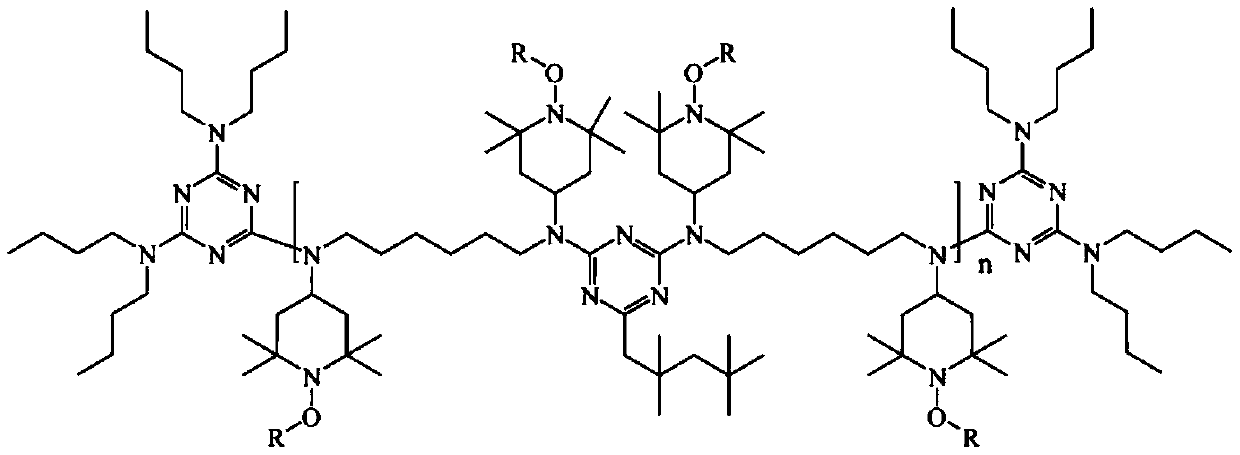

[0029] The preparation method of above-mentioned hindered amine light stabilizer, synthetic route is:

[0030]

[0031] where R 1 for C 1 -C 18 straight-chain alkanes, C 5 -C 7 Naphthenic.

[0032] The preparation method of hindered amine light stabilizer of the present invention comprises the following steps:

[0033] Step 1, add light stabilizer 944, 2,4-bis(di-n-butylamino)-6-chloro-1,3,5-s-triazine, strong base and solvent to the autoclave; Stabilizer 944, 2,4-bis(di-n-butylamino)-6-chloro-1,3,5-s-triazine, strong base, solvent feed ratio is 1:0.2-0.3:0.3-0.6:0.8- 1.2.

[0034] Step 2, pressurize nitrogen to 1.5-2.0MPa, heat to 160-200°C for 3-8h.

[0035] Step 3: lower the temperature, filter, wash, and evaporate the solvent under reduced pressure to obtain intermediate 1.

[0036] Step 4, intermediate 1, water, catalyst (I), 30% hydrogen peroxide solution are mixed; Intermediate 1: 30% hydrogen peroxide feed ratio is 1:0.8-1.2; Catalyst (I) is stannous sulfat...

Embodiment 1

[0042] Put 280g of light stabilizer 944, 74g of 2,4-bis(di-n-butylamino)-6-chloro-1,3,5-s-triazine, 300mL of xylene and 100g of 20% sodium hydroxide solution into the autoclave , replaced with nitrogen several times, pressurized to 2MPa, stirred, and heated to 160°C for 3h. Cool down, filter the reaction solution, wash the organic phase several times with 10% sodium chloride solution, evaporate the solvent under reduced pressure, and obtain intermediate 1.

[0043] Mix 340g of intermediate 1 with 500mL of water, stir at 15°C for 10min, add 20g of sodium tungstate, add dropwise 340g of 30% aqueous hydrogen peroxide, control the temperature between 20°C and 25°C, and continue the heat preservation reaction for 24h. After the reaction, it was extracted three times with 1000 mL of ethyl acetate, and the solvent was removed in vacuo to obtain intermediate 2, which was stored at low temperature until use.

[0044] Dissolve 380g of intermediate 2 in 500mL of ethanol, add 116g of n-p...

Embodiment 2

[0046]Put 280g of light stabilizer 944, 74g of 2,4-di(di-n-butylamino)-6-chloro-1,3,5-s-triazine, 300mL of toluene and 100g of 20% sodium hydroxide solution into the autoclave, Nitrogen was replaced several times, pressurized to 2MPa, stirred, and heated to 160°C for 3h. Cool down, filter the reaction solution, wash the organic phase several times with 10% sodium chloride solution, evaporate the solvent under reduced pressure, and obtain intermediate 1.

[0047] Mix 340g of intermediate 1 with 500mL of water, stir at 15°C for 10min, add 18g of stannous sulfate, add dropwise 340g of 30% aqueous hydrogen peroxide, control the temperature between 20°C and 25°C, and continue the heat preservation reaction for 24h. After the reaction, it was extracted three times with 1000 mL of ethyl acetate, and the solvent was removed in vacuo to obtain intermediate 2, which was stored at low temperature until use.

[0048] Take 380g of intermediate 2 and dissolve in 500mL of ethanol, then add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com