Light stabilizer intermediate and preparation method thereof

A light stabilizer and intermediate technology, which is applied in the field of light stabilizer intermediates and their preparation, can solve problems such as intolerance to extraction, small molecular weight, poor compatibility of polymer materials, etc., and achieve low volatility and low production cost. Effect of low and superior polymer compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

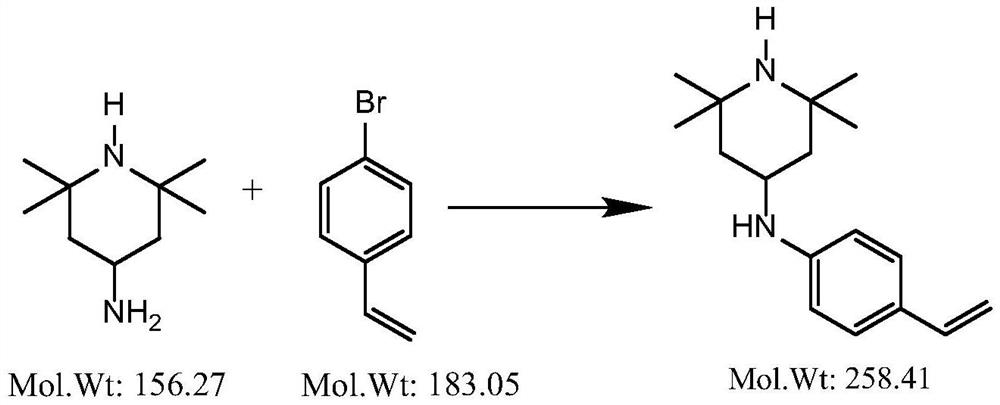

Image

Examples

Embodiment 1

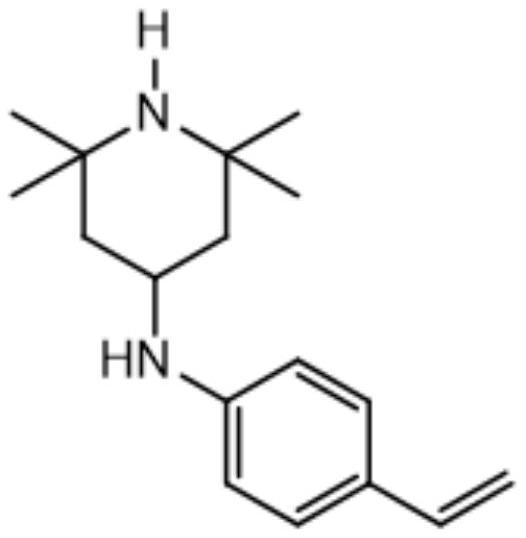

[0023] Add 50g of p-bromostyrene to the reaction kettle, add 100g of xylene and 0.25g of hydroquinone, start stirring to mix evenly, and add 43.5g of 4-amino-2,2,6 dropwise at a temperature of 50-53°C, 6-Tetramethylpiperidine, add 37g of 30% lye dropwise at a temperature of 55-58°C after dropping, keep warm at 85-88°C for 4 hours, wash with water, and remove the solvent by rotary evaporation to obtain intermediate 2,2 , 75.2g of 6,6-tetramethyl-N-(4-vinylphenyl)piperidin-4-amine, the yield was 91.0%;

Embodiment 2

[0025] A preparation method of light stabilizer intermediate, comprising the following steps:

[0026] Add 100g of p-bromostyrene to the reaction kettle, add 250g of xylene and 0.55g of hydroquinone, start stirring to mix evenly, and add 92.5g of 4-amino-2,2,6 dropwise at a temperature of 57-60°C, 6-Tetramethylpiperidine, add 80.5g of 30% lye dropwise at a temperature of 62-65°C after dropping, keep warm at 90-93°C for 5 hours, wash with water, spin evaporate to remove the solvent to obtain intermediate 2, 2,6,6-Tetramethyl-N-(4-vinylphenyl)piperidin-4-amine 152.6g, yield 92.3%;

Embodiment 3

[0028] A preparation method of light stabilizer intermediate, comprising the following steps:

[0029] Add 156g of p-bromostyrene to the reaction kettle, add 624g of xylene and 0.92g of hydroquinone, start stirring to mix evenly, and add 144g of 4-amino-2,2,6,6 dropwise at a temperature of 60-63°C -Tetramethylpiperidine, add 135g of 30% lye dropwise at 63-65°C after dropping, keep warm at 98-100°C for 5.5 hours after dropping, wash with water, and remove the solvent by rotary evaporation to obtain intermediate 2,2, 6,6-Tetramethyl-N-(4-vinylphenyl)piperidin-4-amine 233.7g, yield 90.6%;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com