Small-particle-size low-rank coal pyrolysis technology and equipment coupling multi-stage dust reducing

A small particle size, pyrolysis technology, used in gas dust removal, chemical industry, petroleum industry, etc., can solve the problems of low material temperature, uneven heating, reduced heat transfer efficiency, etc., to improve tar quality, suppress dust generation, The effect of improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

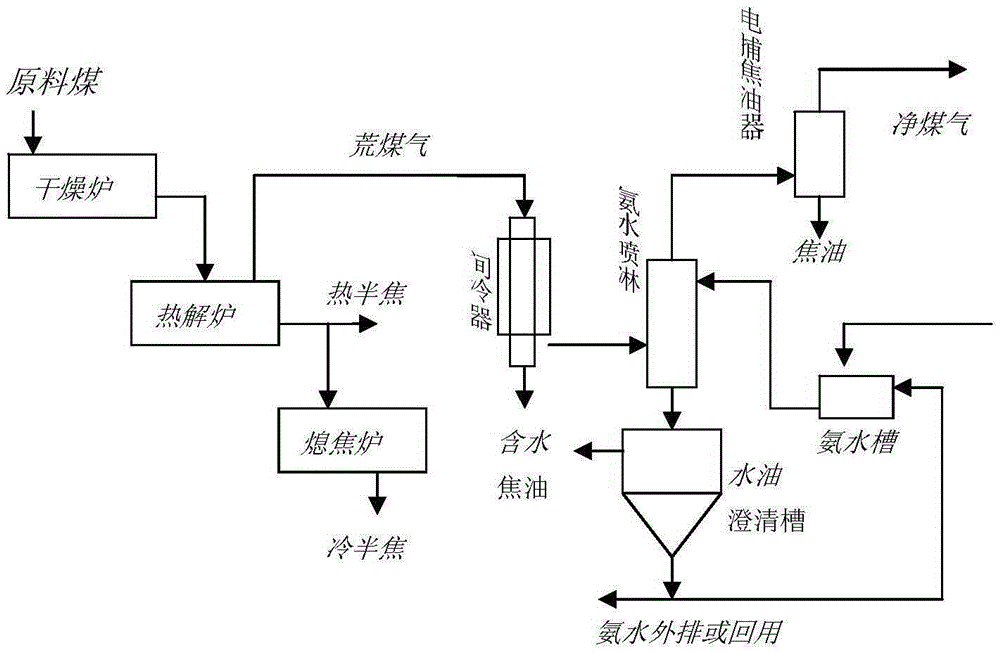

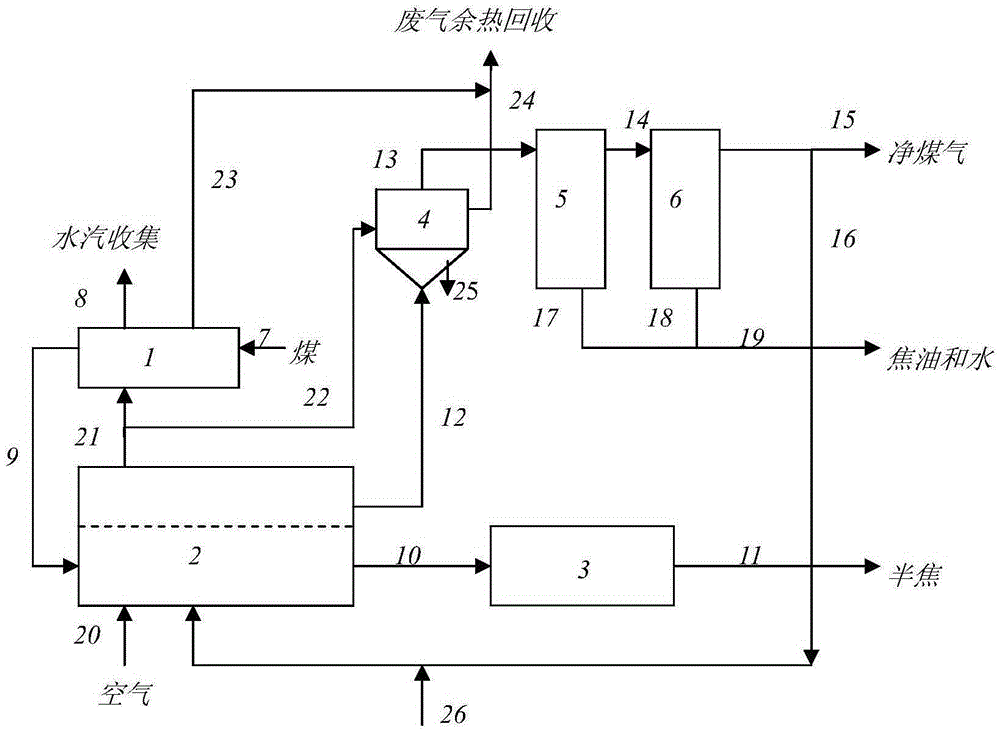

[0044] Such as image 3 As shown, it is a process roadmap for pyrolysis of small particle size low-rank coal coupled with multi-stage dust reduction in the present invention. From a structural point of view, the equipment included in the whole process includes: external heat dryer 1, pyrolysis furnace 2, coke quencher 3, high-temperature dust collector 4, tubular cooler 5, and electric tar collector 6. The external heat dryer 1 is connected to the pyrolysis furnace 2, and the pyrolysis furnace 2 is connected to the coke quencher 3 to form a solid processing path. The pyrolysis furnace 2 is connected to the high-temperature dust collector 4, the high-temperature dust collector 4 is connected to the tubular cooler 5, and the tubular cooler 5 is connected to the electric tar catcher 6 to form a gas treatment path.

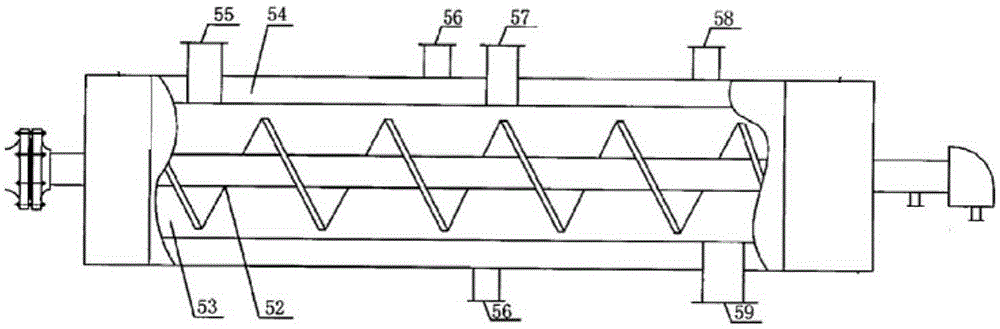

[0045] Such as Figure 4 and Figure 5 As shown, it is a schematic structural diagram of the external heat dryer in the present invention. It includes drive motor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com