A preparation method of a composite membrane with the function of adsorbing and separating heavy metal ions

A heavy metal ion, composite membrane technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of difficult recovery and recycling, and achieve fast adsorption rate and short production cycle. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

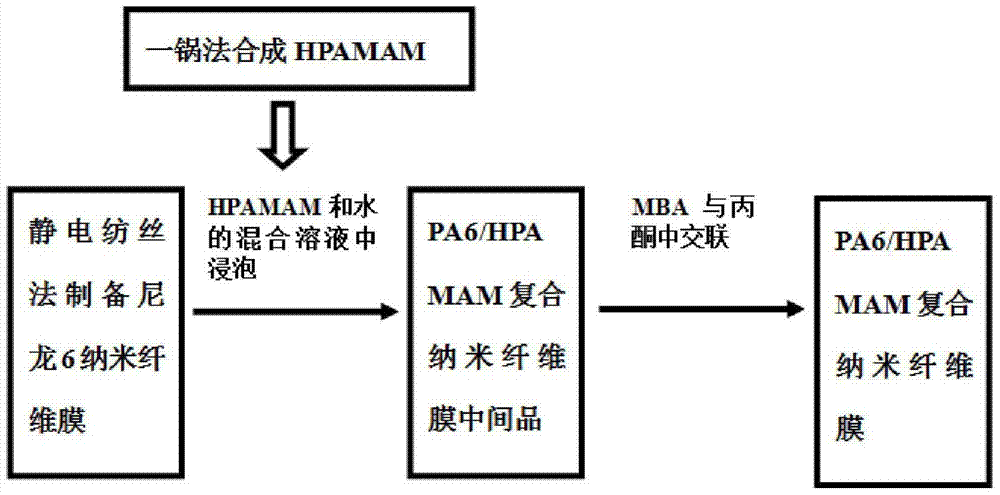

Method used

Image

Examples

Embodiment 1

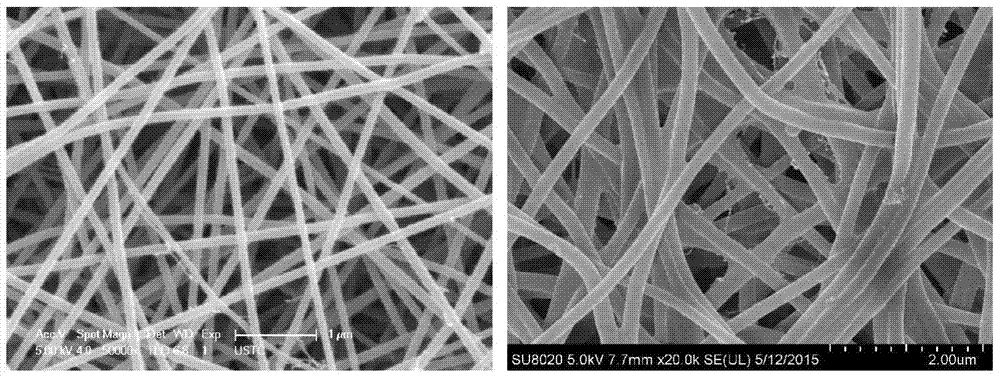

[0037] (1) Dissolve nylon 6 with a mixed solvent of formic acid and acetic acid (mass ratio of formic acid and acetic acid is 1:1), prepare nylon 6 spinning solution with a mass fraction of 17.5wt%, and then adjust the receiving distance to 15cm, voltage 20kV, at room temperature Down electrospinning to produce an electrospun membrane with a thickness of 0.08-0.12 mm;

[0038] (2) Add MBA (N,N-methylenebisacrylamide) (10.175g) and AEPZ (N-aminoethylpiperazine) (8.527g) to 120mL methanol / water mixed solvent (volume of methanol and water ratio of 7:3), polymerized at 50°C for 5 days under constant temperature and condensing reflux conditions, precipitated the resulting product twice in ice acetone, and moved the precipitated polymer into a vacuum drying oven at room temperature, -0.1MPa Dry under vacuum for 12 hours to obtain hyperbranched polyamidoamine, which is then placed in a desiccator for subsequent use.

[0039] (3) Cut the obtained electrospun membrane into a size of 5...

Embodiment 2

[0042](1) Dissolve nylon 6 with a mixed solvent of formic acid and acetic acid (mass ratio of formic acid and acetic acid is 1:1), prepare nylon 6 spinning solution with a mass fraction of 17.5wt%, and then adjust the receiving distance to 15cm, voltage 20kV, at room temperature Down electrospinning to produce an electrospun membrane with a thickness of 0.08-0.12mm;

[0043] (2) Add MBA (N,N-methylenebisacrylamide) (10.175g) and AEPZ (N-aminoethylpiperazine) (8.527g) to 120mL methanol / water mixed solvent (volume of methanol and water ratio of 7:3), polymerized at 50°C for 5 days under constant temperature and condensing reflux conditions, precipitated the resulting product twice in ice acetone, and moved the precipitated polymer into a vacuum drying oven at room temperature, -0.1MPa Dry under vacuum for 12 hours to obtain hyperbranched polyamidoamine, which is then placed in a desiccator for subsequent use.

[0044] (3) Cut the obtained electrospun membrane into a size of 5cm...

Embodiment 3

[0047] (1) Dissolve nylon 6 with a mixed solvent of formic acid and acetic acid (mass ratio of formic acid and acetic acid is 1:1), prepare nylon 6 spinning solution with a mass fraction of 17.5wt%, and then adjust the receiving distance to 15cm, voltage 20kV, at room temperature Down electrospinning to produce an electrospun membrane with a thickness of 0.08-0.12 mm;

[0048] (2) Add MBA (N,N-methylenebisacrylamide) (10.175g) and AEPZ (N-aminoethylpiperazine) (8.527g) to 120mL methanol / water mixed solvent (volume of methanol and water ratio of 7:3), polymerized at 50°C for 5 days under constant temperature and condensing reflux conditions, precipitated the resulting product twice in ice acetone, and moved the precipitated polymer into a vacuum drying oven at room temperature, -0.1MPa Dry under vacuum for 12 hours to obtain hyperbranched polyamidoamine, which is then placed in a desiccator for subsequent use.

[0049] (3) Cut the obtained electrospun membrane into a size of 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com