Method for converting ginsenoside through plant complex enzyme

A technology for transforming human and ginsenosides with compound enzymes is applied in the field of utilizing plant compound enzymes to transform ginsenosides, which can solve the problems of poor specificity, low yield, environmental pollution and the like, and achieve the effects of easy product drying, convenient operation and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Configure LL liquid medium (0.5gNH 4 Cl, 1.0gK 2 HPO 4 , 0.5gKH 2 PO 4 , 0.25gMgSO 4 and 1.0g yeast powder, water 1000ml, pH value 7.0), sterilized at 121°C for 15min, cooled to room temperature; Ginseng was ground into powder, sterilized at low temperature at 50-90°C, then cooled to room temperature; 4.8g Mix the sterilized ginseng powder with 1.2g plant compound enzyme; add LL liquid medium and distilled water to adjust the moisture, the moisture in the solid fermentation system is 50-80%; mix well, seal it, and place it in a constant temperature incubator at 30°C Ferment for 7 days to obtain ginseng fermentation product; use 50-200mL of 80% methanol aqueous solution for the fermentation product, ultrasonically extract at 50°C for 10-50min, filter, and concentrate the filtrate under reduced pressure to obtain the crude ginsenoside extract; add the crude ginsenoside extract to After dissolving in ionic water, extract with saturated n-butanol solution, concentrate ...

Embodiment 2

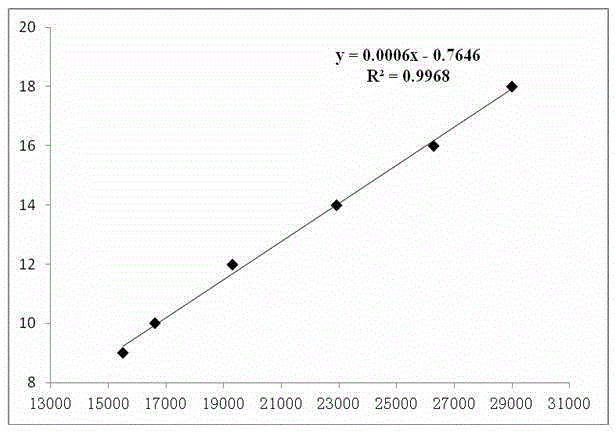

[0023] Configure LL liquid medium (0.5gNH 4 Cl, 1.0gK 2 HPO 4 , 0.5gKH 2 PO 4 , 0.25gMgSO 4 and 1.0g yeast powder, water 1000ml, pH value 7.0), sterilized at 121°C for 15min, cooled to room temperature; Ginseng was ground into powder, sterilized at low temperature at 50-90°C, then cooled to room temperature; 4.8g Mix the sterilized ginseng powder with 1.2g plant compound enzyme; add LL liquid medium and distilled water to adjust the moisture, the moisture in the solid fermentation system is 50-80%;; mix well, seal it, and place it in a 40°C constant temperature incubator The ginseng fermentation product was obtained by medium fermentation for 8 days; the fermentation product was extracted with 50-200mL of 80% methanol aqueous solution, ultrasonically extracted at 50°C for 10-50min, filtered, and the filtrate was concentrated under reduced pressure; extraction and concentration under reduced pressure to obtain solid fermented ginsenoside extract. According to the results ...

Embodiment 3

[0025] Configure LL liquid medium (0.5gNH 4 Cl, 1.0gK 2 HPO 4 , 0.5gKH 2 PO 4 , 0.25gMgSO 4 and 1.0g yeast powder, water 1000ml, pH value 7.0), sterilized at 121°C for 15min, cooled to room temperature; Ginseng was ground into powder, sterilized at low temperature at 50-90°C, then cooled to room temperature; 3.6g Mix the sterilized ginseng powder with 2.4g plant compound enzyme; add LL liquid medium and distilled water to adjust the moisture, the moisture in the solid fermentation system is 50-80%; mix well, seal it, and place it in a constant temperature incubator at 50°C Ferment for 9 days to obtain ginseng fermentation product; use 50-200mL of 80% methanol aqueous solution for the fermentation product, ultrasonically extract at 50°C for 10-50min, filter, and concentrate the filtrate under reduced pressure; add deionized water to dissolve, then extract with saturated n-butanol solution , concentrated under reduced pressure to obtain solid fermented ginsenoside extract. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com