Epoxy drawn grain anticorrosive floor

An epoxy wrinkle and wrinkle surface technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings and other directions, can solve the problems of affecting the owner's production, prone to cracking, slow construction speed, etc., to achieve low maintenance costs, increase wrinkle surface , the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

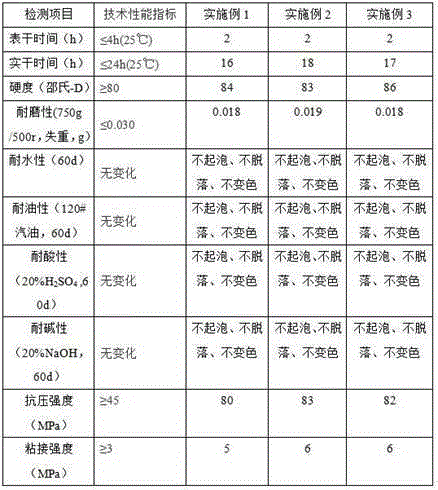

Embodiment 1

[0015] An epoxy corrugated surface anticorrosion floor, comprising an anticorrosion primer layer, an anticorrosion layer, an anticorrosion intermediate coating, and a corrugated surface anticorrosion layer; the corrugated surface anticorrosion layer is composed of A component and B component, and A group The composition of the component is: 40 parts of epoxy bisphenol A type epoxy resin, 32.5 parts of phenolic resin, 0.5 part of dicyclohexylmethane diisocyanate, 8 parts of cyclohexane, 2 parts of n-butanol, 0.36 parts of crotonic acid, 0.86 parts of cobalt naphthenate, 1.2 parts of wetting and dispersing agent, 0.9 parts of leveling agent, 0.6 parts of defoamer, 15 parts of diatomaceous earth, 8 parts of mica powder; the composition of component B is: tert-butyl styrene 10 12 parts, 12 parts of styrene, 3.6 parts of diethylenediamine, 0.8 parts of toluenesulfonic acid; the weight ratio of component A and component B is 10:3.

[0016] The wetting and dispersing agent is BYK-220...

Embodiment 2

[0019] An epoxy corrugated surface anticorrosion floor, including an anticorrosion primer layer, an anticorrosion layer, an anticorrosion intermediate coating, and a corrugated surface anticorrosion layer, the corrugated surface anticorrosion layer is composed of A component and B component, and A group The components are: 45 parts of epoxy bisphenol A type epoxy resin, 35 parts of phenolic resin, 0.3 parts of dicyclohexylmethane diisocyanate, 7 parts of cyclohexane, 2 parts of n-butanol, 0.2 parts of crotonic acid, 0.8 parts of cobalt naphthenate, 1.4 parts of wetting and dispersing agent, 0.9 parts of leveling agent, 0.6 parts of defoamer, 13 parts of diatomaceous earth, 8 parts of mica powder; the composition of component B is: tert-butyl styrene 12 10 parts, 10 parts of styrene, 4 parts of diethylenediamine, 0.8 parts of toluenesulfonic acid; the weight ratio of component A and component B is 10:3.

[0020] The wetting and dispersing agent is BYK-220S, the leveling agent i...

Embodiment 3

[0023] An epoxy corrugated surface anticorrosion floor, including an anticorrosion primer layer, an anticorrosion layer, an anticorrosion intermediate coating, and a corrugated surface anticorrosion layer, the corrugated surface anticorrosion layer is composed of A component and B component, and A group The composition of the component is: 50 parts of epoxy bisphenol A epoxy resin, 40 parts of phenolic resin, 0.6 part of dicyclohexylmethane diisocyanate, 8 parts of cyclohexane, 3 parts of n-butanol, 0.4 part of crotonic acid, 0.9 parts of cobalt naphthenate, 1.8 parts of wetting and dispersing agent, 1.0 parts of leveling agent, 0.7 parts of defoamer, 16 parts of diatomaceous earth, 10 parts of mica powder; the composition of component B is: tert-butyl styrene 15 15 parts, 15 parts of styrene, 6 parts of diethylenediamine, 1.0 parts of toluenesulfonic acid; the weight ratio of component A and component B is 10:3.

[0024] The wetting and dispersing agent is BYK-220S, the level...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com