Pretreatment method for detecting metal elements in kapok powder

A technology for metal elements and kapok, which is applied in the field of pretreatment for detecting metal elements in kapok powder, can solve the problems of cumbersome operation process, large amount of reagents, polluted components, etc., and achieves good digestion effect, complete digestion and uniform dispersion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

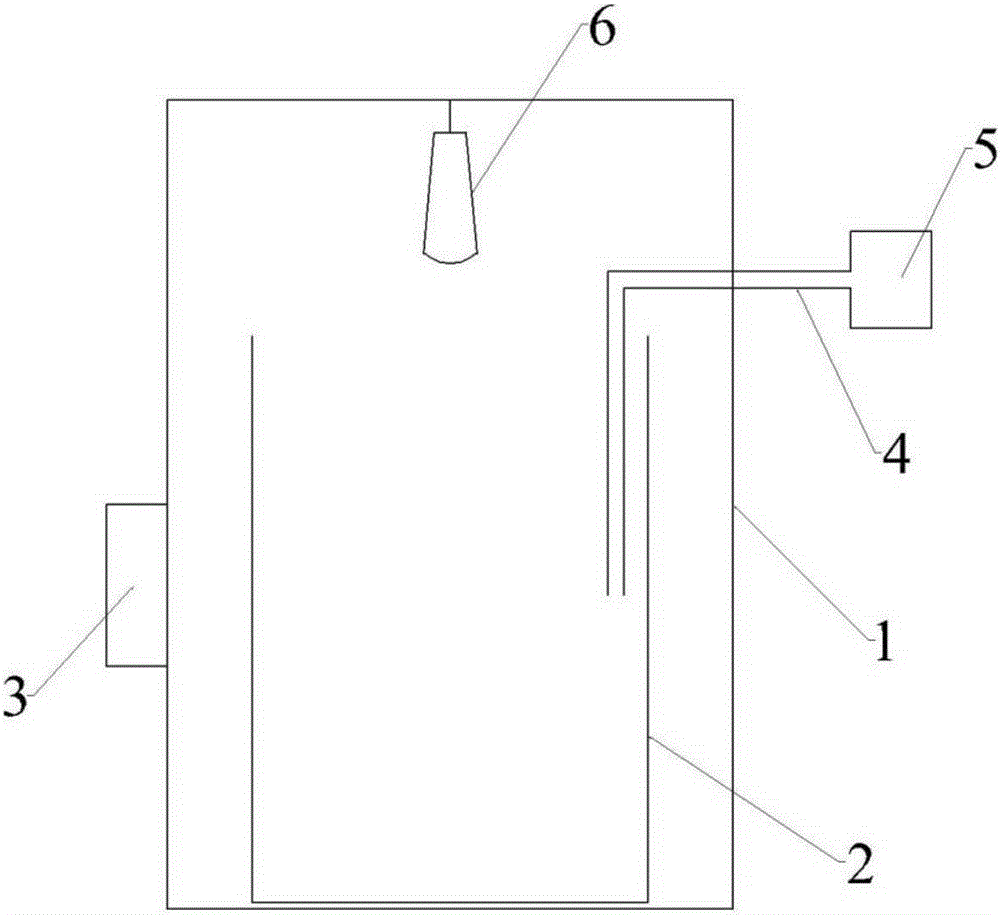

Image

Examples

example 1

[0025] A pretreatment method for detecting metal elements in kapok powder, comprising the following steps:

[0026] Step 1, pulverizing the kapok and putting it into a digestion tank, adding nitric acid with a mass fraction of 15% and hydrogen peroxide with a mass fraction of 30%, and standing for 10 hours; wherein, the nitric acid and hydrogen peroxide in each gram of kapok The addition amount is respectively 8 milliliters and 3 milliliters;

[0027] Step 2. Put the digestion tank into the digestion apparatus for microwave digestion. The microwave power used is 1600W; the specific procedure of microwave digestion is: first keep at 115°C for 3 minutes, then raise the temperature to 145°C within 3 minutes and Hold for 3 minutes, then increase the temperature to 158°C within 3 minutes and hold for 3 minutes, and finally increase the temperature to 175°C within 3 minutes and hold for 8 minutes;

[0028] Step 3. Transfer the digestion sample solution in the digestion tank to a po...

example 2

[0035] A pretreatment method for detecting metal elements in kapok powder, comprising the following steps:

[0036] Step 1, pulverizing the kapok and putting it into a digestion tank, adding nitric acid with a mass fraction of 15% and hydrogen peroxide with a mass fraction of 30%, and standing for 14 hours; wherein, the nitric acid and hydrogen peroxide in each gram of kapok The addition amount is respectively 12 milliliters and 5 milliliters;

[0037] Step 2. Put the digestion tank into the digestion apparatus for microwave digestion. The microwave power used is 1600W; the specific procedure of microwave digestion is: first keep at 125°C for 7 minutes, then raise the temperature to 155°C within 7 minutes and Hold for 7 minutes, then increase the temperature to 165°C within 7 minutes and hold for 7 minutes, and finally increase the temperature to 185°C within 7 minutes and hold for 12 minutes;

[0038] Step 3. Transfer the digestion sample liquid in the digestion tank to a poly...

example 3

[0045] A pretreatment method for detecting metal elements in kapok powder, comprising the following steps:

[0046] Step 1, putting kapok pulverized into a digestion tank, adding nitric acid with a mass fraction of 15% and hydrogen peroxide with a mass fraction of 30%, and standing for 12 hours; wherein, the nitric acid and hydrogen peroxide in each gram of kapok The addition amount is respectively 10 milliliters and 4 milliliters;

[0047] Step 2. Put the digestion tank into the digestion apparatus for microwave digestion. The microwave power used is 1600W; the specific procedure of microwave digestion is: first keep at 120°C for 5 minutes, then raise the temperature to 150°C within 5 minutes and Hold for 5 minutes, then increase the temperature to 160°C over 5 minutes and hold for 5 minutes, and finally increase the temperature to 180°C over 5 minutes and hold for 10 minutes.

[0048] Step 3. Transfer the digestion sample liquid in the digestion tank to a polytetrafluoroeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com