Electrolyte for in-situ growth of barium strontium titanium ferroelectric film on surface of titanium substrate and preparing method of film

A technology of barium strontium titanate and ferroelectric thin film, which is applied in the field of functional thin film materials, can solve the problems of affecting thin film performance, loose film surface, large roughness value, etc., and achieve fast film forming speed, high bonding strength and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

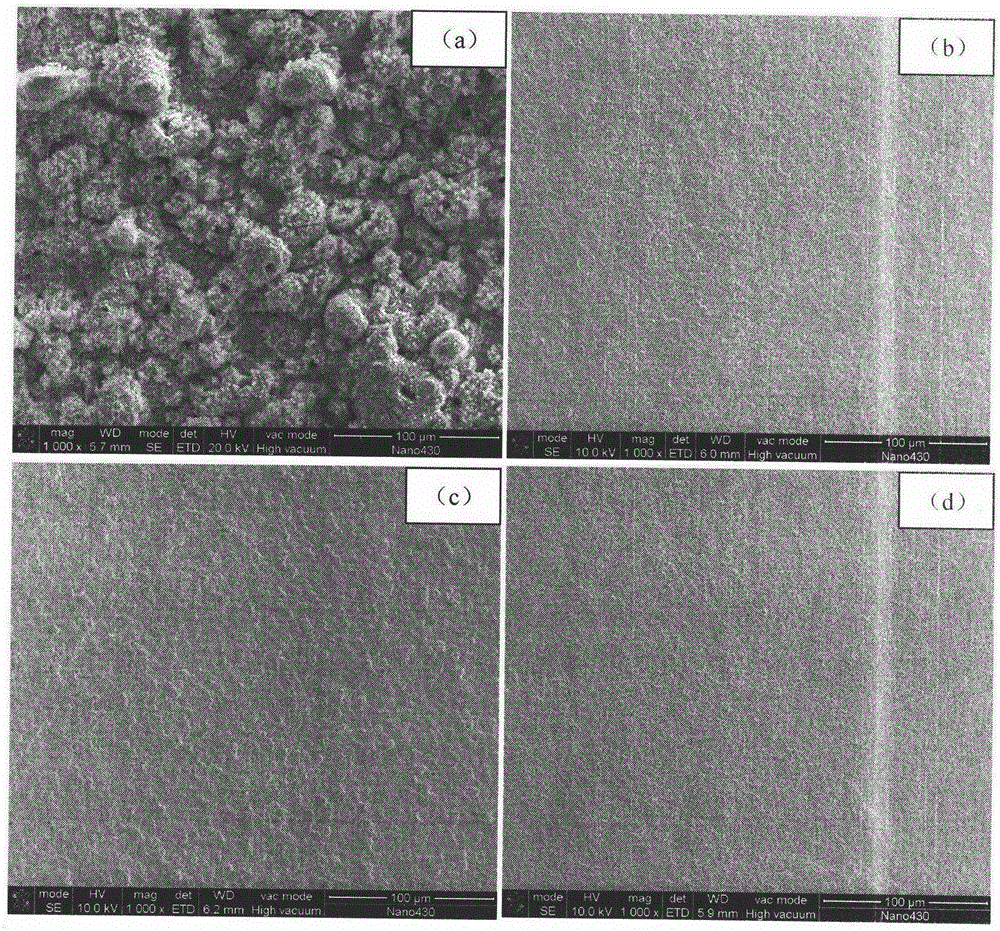

[0044] In-situ growth of barium strontium titanate ferroelectric thin film on commercially pure titanium TA2 specifically includes the following steps:

[0045] (1) Sample preparation: Cut the Ti plate into a substrate of 40*20*2mm, and grind the Ti substrate step by step with 180# to 1000# sandpaper until the surface is bright and smooth.

[0046] (2) Pre-treatment of the sample: Wash the polished Ti sheet in acetone and deionized water respectively, and dry it for later use.

[0047] (3) Electrolyte preparation: 0.5mol / LBa(OH) 2 , 0.5mol / LSr(OH) 2 and 0.03mol / LEDTA as the solute, and deionized water as the solvent to prepare 1L of electrolyte. The prepared electrolyte was stirred on a magnetic heating stirrer for 30 minutes, the heating temperature was set at 60° C., and the rotation speed was 1500 r / min.

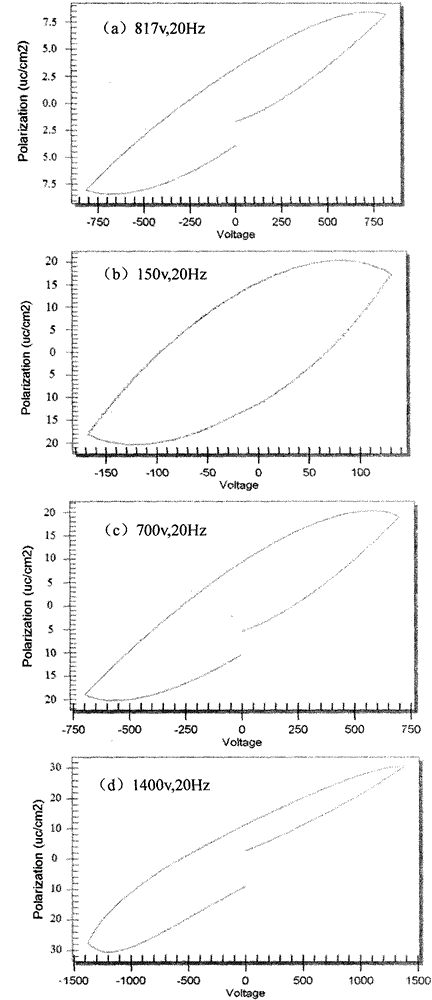

[0048] (4) Ferroelectric thin film preparation: connect the titanium sheet pretreated in steps (1) and (2) to the anode, and place it in the electrolyte solution in st...

Embodiment 2

[0051] In this embodiment, except for the composition of the electrolyte and the reaction time, other features are the same as in Embodiment 1.

[0052] The electrolyte composition is as follows: with 0.5mol / LBa(OH) 2 , 0.5mol / LSr(OH) 2 and 0.05mol / LEDTA as the solute, and deionized water as the solvent to prepare 1L of electrolyte.

[0053] The reaction time of this embodiment is 15min.

[0054] The phase composition and surface morphology of the obtained film are similar to those in Example 1, and the surface roughness of the film is about 0.408um. The hysteresis loop of the thin film measured by the RADIANT Precision Premier II system is as follows: image 3 As shown in (c), under the condition of 700V applied electric field and 20Hz frequency, the remnant polarization is about 12μC / cm 2 . The dielectric constant of the film is 455.3 and the dielectric loss is 0.167 under the condition of 1KHz measured by AGILENT4284APrecisionLCRMETER system (test signal is 0.1V).

Embodiment 3

[0056] In this embodiment, except for the composition of the electrolyte and the reaction time, other features are the same as in Embodiment 1.

[0057] The electrolyte composition is as follows: with 0.5mol / LBa(OH) 2 , 0.5mol / LSr(OH) 2 and 0.06mol / LEDTA as the solute, and deionized water as the solvent to prepare 1L of electrolyte.

[0058] The reaction time of this embodiment is 15min.

[0059] The phase composition and surface morphology of the obtained thin film are similar to those in Example 1, and the surface roughness of the thin film is about 0.422um. The hysteresis loop of the thin film measured by the RADIANT Precision Premier II system is as follows: image 3 As shown in (d), under the conditions of 1400V applied electric field and 20Hz frequency, the remnant polarization is about 10μC / cm 2 . The dielectric constant of the film is 387.2 and the dielectric loss is 0.456 under the condition of 1KHz measured by AGILENT4284APrecisionLCRMETER system (test signal is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Remanent polarization | aaaaa | aaaaa |

| Surface roughness value | aaaaa | aaaaa |

| Surface roughness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com