Preparation method of silicone modified acrylic hydrogel antifouling coating

An antifouling coating, acrylic technology, applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problems of loss of antifouling performance, hydrogel surface damage, and change of material surface properties, etc. To achieve the effects of prolonging the anti-pollution period, scientific design and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

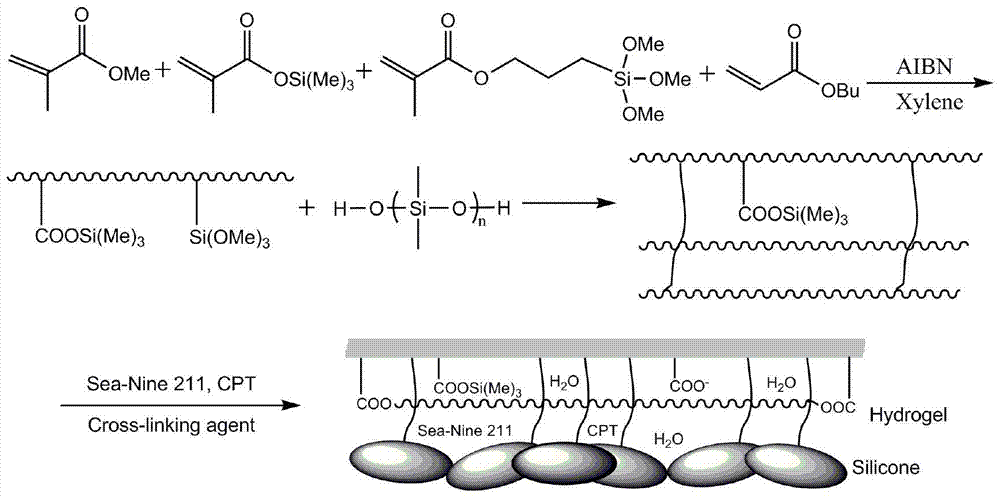

[0022] (1) Synthesis of silicone modified acrylic resin:

[0023] Add 20g of butyl acetate and 180g of xylene into a four-necked flask equipped with a stirrer, reflux condenser, constant pressure dropping funnel, and thermometer, raise the temperature to 90°C, and then weigh 50g of methyl methacrylate, 48g of formazan Trimethylsilyl acrylate, 10g γ-(methacryloyloxy) propyltrimethoxysilane, 92g n-butyl acrylate, 1.5g azobisisobutyronitrile mixed solution, through constant pressure dropping funnel After 3 hours of constant-speed dropwise addition, 0.5 g of azobisisobutyronitrile was added, and the reaction was continued for 3 hours. Cool to 60°C, add 20g of hydroxy silicone oil, react for 12h, cool to room temperature, and finally add 30g of xylene to adjust the dilution of the resin to complete the reaction.

[0024] The specific synthetic route is as figure 1 shown.

[0025] (2) Preparation of two-component hydrogel antifouling coating: the coating contains two components A...

Embodiment 2

[0030] (1) Synthesis of silicone modified acrylic resin:

[0031] Add 20g of butyl acetate and 180g of xylene into a four-necked flask equipped with a stirrer, reflux condenser, constant pressure dropping funnel, and thermometer, raise the temperature to 90°C, and then weigh 50g of methyl methacrylate, 48g of formazan Tributylsilyl acrylate, 10g γ-(methacryloyloxy)propyltrimethoxysilane, 62g n-butyl acrylate, 30g 2-ethylhexyl acrylate, 1.5g azobisisobutyronitrile The mixed solution was added dropwise at a constant rate for 3 hours with a constant pressure dropping funnel, and 0.5 g of azobisisobutyronitrile was added to continue the reaction for 3 hours. Cool to 60°C, add 20g of hydroxyl silicone oil (average molecular weight: 400), react for 12h, cool to room temperature, and finally add 30g of xylene to adjust the dilution of the resin to complete the reaction.

[0032] Concrete synthetic route is consistent with embodiment 1.

[0033] (2) Preparation of two-component hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com