Curing resin composition and semiconductor device employing same

A technology of curable resin and composition, which can be used in semiconductor devices, semiconductor/solid-state device parts, electric solid-state devices, etc., and can solve problems such as lack of records

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0204] Hereinafter, the present invention will be described in more detail with reference to examples, but the present invention is not limited to these examples.

[0205] reaction products and products 1 H-NMR analysis can be performed using JEOLECA500 (500MHz). In addition, the measurement of the number-average molecular weight and weight-average molecular weight of the reaction product and the product can use AllianceHPLC system 2695 (manufactured by Waters), RefractiveIndexDetector2414 (manufactured by Waters), chromatographic column: TskgelGMH HR -M×2 (manufactured by Tosoh Co., Ltd.), guard column: TskgelguardcolumnH HR L (manufactured by Tosoh Co., Ltd.), column oven: COLUMN HEATERU-620 (manufactured by Sugai), solvent: THF, and measurement conditions: 40°C.

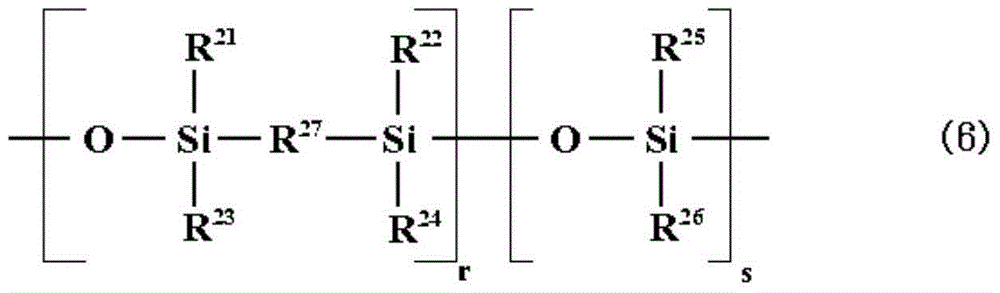

[0206] [Polyorganosiloxane (A)]

[0207] As the polyorganosiloxane (A), the following products were used.

[0208] GD-1125A: manufactured by Changxing Chemical Industry Co., Ltd., vinyl content 1.13% by weight...

Synthetic example 1

[0214] 15.86 g of phenyltriethoxysilane (manufactured by Shin-Etsu Chemical Co., Ltd.) and 6.16 g of methyl isobutyl ketone (MIBK) were charged into the reaction vessel, and the mixture thereof was cooled to 10°C. To the above mixture were added dropwise 4.32 g of water and 0.16 g of 5N hydrochloric acid (2.4 mmol as hydrogen chloride) over 1 hour. After the dropwise addition, their mixture was kept at 10°C for 1 hour. Thereafter, 26.67 g of MIBK was added to dilute the reaction solvent.

[0215] Next, the temperature of the reaction container was raised to 70° C., and when the temperature reached 70° C., 0.16 g (25 mmoles as hydrogen chloride) of 5N hydrochloric acid was added, and polycondensation reaction was performed in a nitrogen atmosphere for 4 hours.

[0216] Then, 11.18 g of divinyltetramethyldisiloxane and 3.25 g of hexamethyldisiloxane were added to the reaction solution, and a silylation reaction was performed at 70° C. for 4 hours. Thereafter, the reaction solu...

Synthetic example 2

[0227] Feed 210.9g of 3-glycidoxypropyltrimethoxysilane, 20.8g of tetraethoxysilane, 210.9g of methanol, 20.8g of ethanol and 17.4g of potassium fluoride (1% ethanol solution) in the reaction vessel, And their mixture was warmed to 50°C.

[0228] Next, 16.2 g of water and 16.2 g of ethanol were dripped over 30 minutes, and after further heating up, polycondensation reaction was performed under reflux for 4 hours.

[0229] Thereafter, volatile components were distilled off while raising the temperature to 80° C. under normal pressure. Thereafter, the remaining volatile components were distilled off while heating up to 100° C. under reduced pressure (30 Torr), to obtain a colorless and transparent liquid reaction product (141.5 g).

[0230] [Zinc compound (E)]

[0231] As the zinc compound (E), the following products were used.

[0232] Zinc octanoate: manufactured by Nippon Chemical Industry Co., Ltd., trade name "NIKKAOcthix Zinc" (Zn: 15%)

[0233]

[0234] Examples 1-5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com